After a challenging winter and spring for vehicle batteries, Rotronics provides some top tips to ensure that vehicles are in prime condition and ready for summer.

This year’s challenging winter and spring did one good thing – show us all how big the effect of weather

conditions is on vehicle batteries. Badly maintained fleet batteries cost businesses a lot of money and now we are in the warmer season, it is important that lessons are learnt from the previous few months.

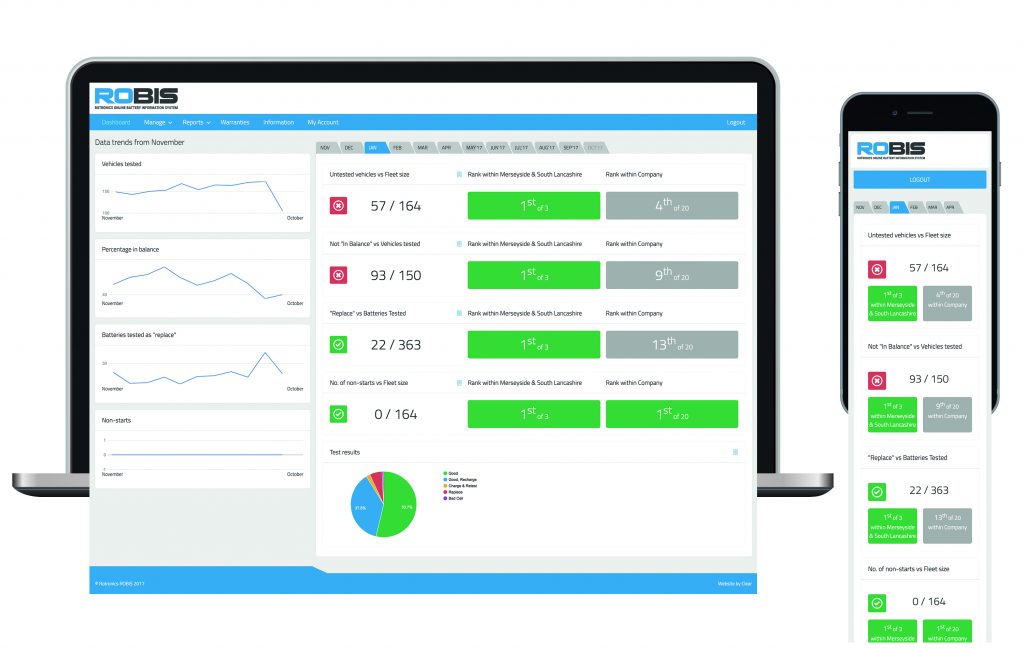

To reduce non-starts, Rotronics has developed ROBIS (Rotronics Online Battery Information System), a web-based dashboard and reporting system that collects battery and electrical data from a number of national/regional fleet workshop sources and will update software across the fleet.

With ROBIS, teams can access clear measurements for fleet battery performance, providing workshops with a powerful measurement tool that will ensure that they can closely manage their processes and budgets.

Ken Clark, Rotronics Managing Director, says: “From active users of our ROBIS system, we have identified that, from the beginning of November 2017 to the end of February 2018, on analysis of nearly 53,000 batteries from PSV and commercial vehicles within the segments of commercial fleets, trucks and buses, 52% of batteries were in a good condition and the rest needed charging or replacement.

Ken Clark, Rotronics Managing Director, says: “From active users of our ROBIS system, we have identified that, from the beginning of November 2017 to the end of February 2018, on analysis of nearly 53,000 batteries from PSV and commercial vehicles within the segments of commercial fleets, trucks and buses, 52% of batteries were in a good condition and the rest needed charging or replacement.

One in every two vehicles needed to have their batteries charged or replaced over the winter months.

“In addition, 15,000 of these batteries had voltages of below 12.4V and this is the point at which sulphation occurs. 14% of these tests resulted in a battery having to be replaced, equating to 7,000 batteries with a revenue of approximately £100 per battery. That totals around £700,000 of cost.”

While winter can affect a battery’s performance by up to 50%, the heat of the summer can also incur increased power demands. The processes of cooling systems, stop starts in summer traffic queues and longer than average vehicle idling spells trouble for a vehicle’s battery. The resultant pressure means it will be using more power than the electrical system can keep up with, with the increased external temperature causing loss of efficiency.

Rotronics has therefore come up with some tips that technicians can look to advise their customers on, so fleets can keep their vehicles on the road for longer.

► Make sure that your Booster Packs are charged and fully serviceable

► If you own or manage a fleet, make sure that the chargers and testers are fully operational, all of the time

► Run a visual battery health check; look for signs of corrosion, excessive electrolyte staining and gassing

► Test and charge to keep battery voltages above 12.5V, to prevent excessive deep cycling and risk of sulphation

► Charge at every opportunity

► The batteries should be in balance – 24V battery sets will only perform efficiently if both voltages and cranking amps are of similar values

► If you are using non-maintenance free batteries, be mindful when checking the electrolyte levels – if the battery is in a low state of charge, the electrolyte will be lower than you would expect

► If you top up a battery that is flat with electrolyte, there is a high risk the battery will be overfilled, causing the cells to expand as the battery takes on current

► Never top up flat batteries with electrolyte

► Always charge first, providing that the cells aren’t exposed