As electric LCVs become more and more commonplace, it is increasingly important to keep up with the new technology. Pico looks at a Renault Kangoo with a charging issue and the hurdles that diagnosing this type of fault brings.

Before we start, we have to talk about safe working with EVs, particularly when discussing charging issues. Firstly, please do not use this case study as a training or instructional guide for working on these vehicles – it is for informational purposes and intended only to give you an idea as to the possible applications of Pico Automotive products.

Secondly, the required CAT ratings of any measurement tools and accessories you use to diagnose faults on a charging EV depend on the part of the mains distribution network to which the vehicle’s charging station is connected (because the possible exposure to transient voltages or short circuit currents changes within the mains distribution network). This is irrespective of whether you are testing the High Voltage (HV) or, say, the 12V system on the vehicle.

Generally, an EV charging station is connected to the mains network after the main distribution board/circuit-breaker/ junction box (i.e. on their outlet) within a building. Therefore, your test equipment should have a CAT rating of III or IV when testing an EV connected to it. However, if the EV charging station is connected to the mains network before the main distribution board/circuit-breaker/ junction box, then your equipment must have a CAT rating of IV.

Without knowing (via proper investigation) exactly how a charging station is connected to the mains network, you should use only CAT IV rated equipment when carrying out measurements on a vehicle connected to a charger.

In this case study, we know that the vehicle’s charging station is connected to the mains network after the distribution board. Therefore, we know we can safely use our CAT III rated differential probe (and connectors) to carry out all our 12 V system measurements (not just HV measurements) in this case.

The vehicle

Renault, along with Nissan, are certainly one OEM that has been around the longest when it comes to full Battery Electric Vehicle here in the UK which means, as they age, the faults start to appear. This 2014 Renault Kangoo ZE is a full BEV, with the battery being underneath the vehicle’s floor pan.

Charging is done with an EVSE and connection made using the type 2 connector with the vehicle charging inlet being behind the badge on the front grill. Being the 400 version of the 5AM engine means this Kangoo cannot support rapid charging; this means everything is done through the On- Board Charger. Unfortunately, this means charging isn’t exactly fast with typical charge times of 11 hours from a flat battery to fully charged on a 3kW home supply. The customer complaint here, though, is the vehicle doesn’t charge at all.

The inspection

The first step is a quick interview with the customer – as always – to get a better idea of the issue and to ensure we can confirm the correct fault. The customer was unsure when the fault initially started as they were still connecting the vehicle overnight but, due to short journeys and a very slow charge time, it only became obvious when the battery continued to deplete.

The vehicle had already been through a number of hands, with the last one reporting that, due to a dead rat on the undertray, there could be rodent damage and so the OBC and inverter needs to be replaced.

Needless to say, a visual inspection was done first to ensure that we were free from rodents and any potential health hazards, but more importantly, if there were any exposed HV cables. All was OK and, continuing with the diagnosis, the next step was to confirm the fault.

Using the customer’s supplied home-charging cable, we connected to a mains socket and switched on. The indicators on the EVSE all illuminated as expected and no fault was being reported. Then connecting to the vehicle, the latch engaged indicating the vehicle detected a charge cable and the indicator on the dash also verified this (Fig. 1).

Typically, when you connect an EVSE to a vehicle, you will then hear the contactors ‘click’ in order to connect the HV Battery to the on-board charger and so allowing the battery to charge. In some cases, you will also hear the fans or cooling system starting when charging has begun. But, when connecting to the Kangoo, nothing was heard. Disconnecting the charge cable, we then moved to DTC’s.

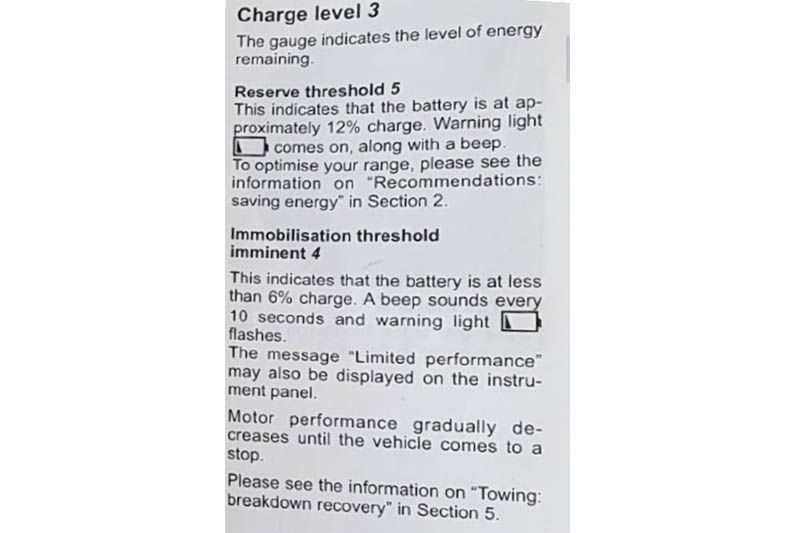

Checking for any fault codes was next on the list, although the only warnings on the instrument cluster were for low battery. Fault codes were relating to the low HV battery as expected but nothing else to give any type of direction. Looking at the live data, we confirmed that the SOC of the HV battery was at 3% which was backed up by the vehicle’s sound and visual warnings with the ignition on.

As shown in Fig. 2, 3% means that the immobilisation threshold is imminent. This is a dangerous level for a HV battery as it will reach a point when even charging could not take place when connected to an EVSE. If it were to drop much lower the battery would have to be removed to be charged with an HV battery recovery system. There are tools if a HV battery has completely discharged and would no longer put the vehicle into ready but it’s better for everyone if you could prevent getting to that stage.

Connecting the charger

To better understand what happens when we connect a charger to a vehicle, we should understand what the expected behavior should be. Typically, most EVs will follow the J1772 protocol, which is standard used for a vehicle to communicate to an EVSE. There are those that fall outside of this with the CHAdeMO and Tesla specific connectors operating slightly differently.

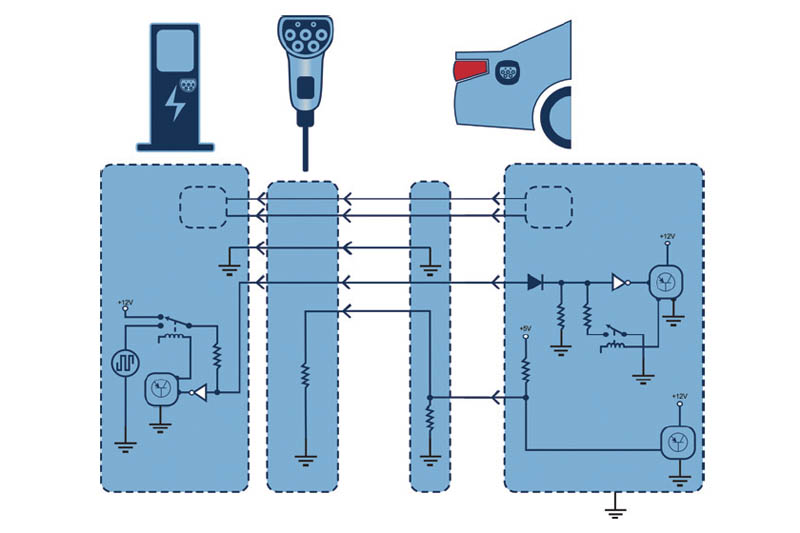

The Type 2 version communicates with the vehicle using a PWM signal and a series of resistors and transistors that control the electrical path. As mentioned at the beginning, this isn’t a training substitute and Pico would advise anyone to get their certification to work on hybrid and electric vehicles.

Here in the UK, there are a few options with the IMI route being the most popular. ZF also offers a High Voltage Expert route through their Technical Training program. To keep it very brief, the EVSE and the vehicle communicate using the PP and CP circuits. On the Type 2 connectors, the PP is there to inform the vehicle a connector is present and what the maximum current the connector can deliver. The EVSE may be able to physically deliver more but the vehicle will only take the current the connector is rated for to prevent overheating.

The CP circuit defines the different stages the vehicle is at during connection. With no connection to the vehicle, there should be a constant +12V signal from the CP terminal until connected to the vehicle inlet. Upon connection due to a number of resistors this pulls the +12V down to approximately 9V. This informs the EVSE that connection to the vehicle has been made and it now delivers a 1 kHz, ±12V PWM signal.

This PWM is important as the duty determines the amount of current that is available to the vehicle, which is still capped by the connector rating. Once the vehicle is happy that all the conditions have been met, it will switch another resistor which then pulls the +9V signal down to approximately +6V to commence charging. There are other voltage levels that it could change to depending on the functionality of the vehicle, such as venting the battery pack but the important ones are +9V and +6V (Fig. 3).

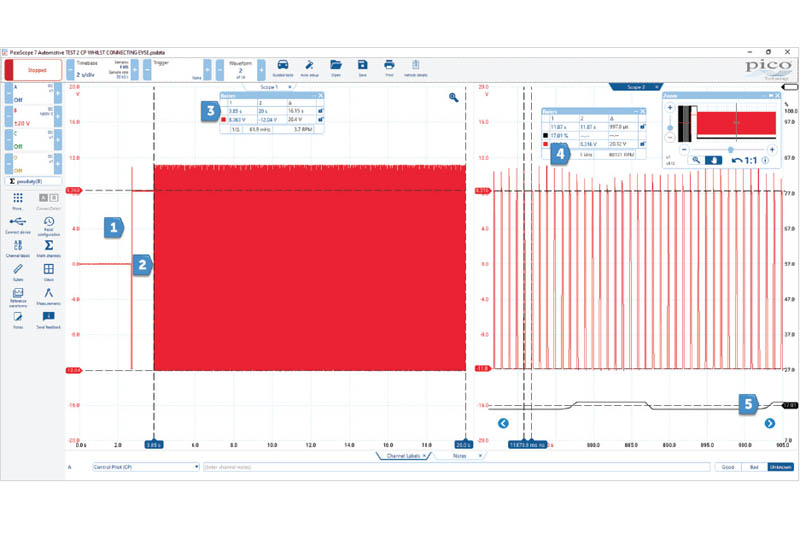

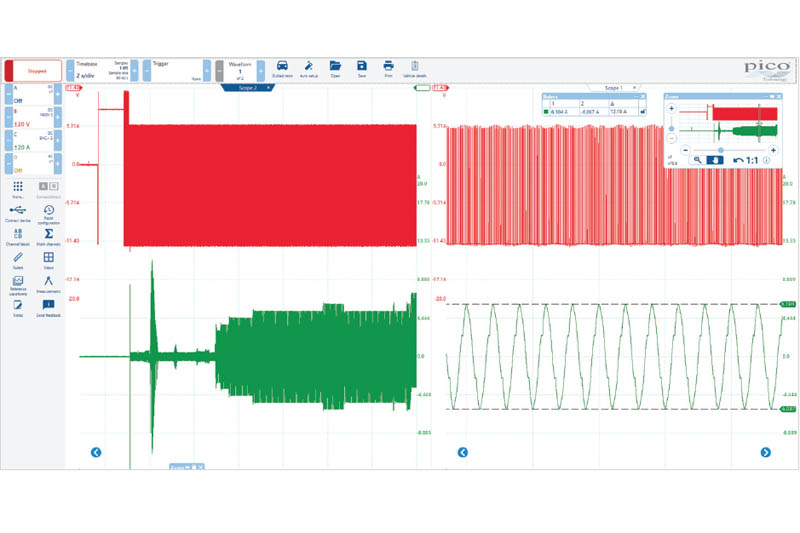

Taking all the necessary steps to ensure safety for the technician and the equipment we connected to the CP circuit at the On- Board Charger, OBC, using the active differential probe. The key was removed from the vehicle to ensure connections are made as per the customer, then the charging connector was connected to the vehicle inlet.

- EVSE connected to vehicle

- PWM signal starts and voltage drops to approximately 8.5V

- Time whilst in waiting for charging to commence

- 1kHz PWM frequency

- Maths channel duty showing 17%

From Fig. 4, we can see where the vehicle detected an EVSE and we can see the 1kHz signal start. This, along with the latching of the connector, tells us that PP circuit must be OK. As the PP terminal is the first to make connection, if there was anything wrong here, we wouldn’t see the PWM signal.

You might question why the waveform shows +9V and +6V but still shows a -12V? The EVSE generates a ±12V square wave which is sent along the CP circuit. Inside the OBC, we have a diode that will allow the block the negative part, but as we are connected on the outside of the OBC, the scope will see both the positive and negative part of the signal.

By letting the capture run, we are expecting the voltage level of the PWM signal to drop which would mean the vehicle has accepted the connector and closed the contactors on the HV battery to allow the OBC to charge the battery. However, we never saw this change.

What could prevent the contactors from closing? The signalling between the EVSE and the vehicle appears to be good so all that remains is the communication between the OBC and the Battery Management System (BMS). The vehicle drove to the workshop without any warning lights, so drivability is fine but it’s just the charging that is an issue.

Reaching a conclusion

The next part was more luck than judgement, but it’s nice to have some on your side from time to time! We reconnected the scan tool to double check for any change with DTCs and to do so involves switching the ignition on but I’d forgotten that I’d left the EVSE connected. Not good practise I know.

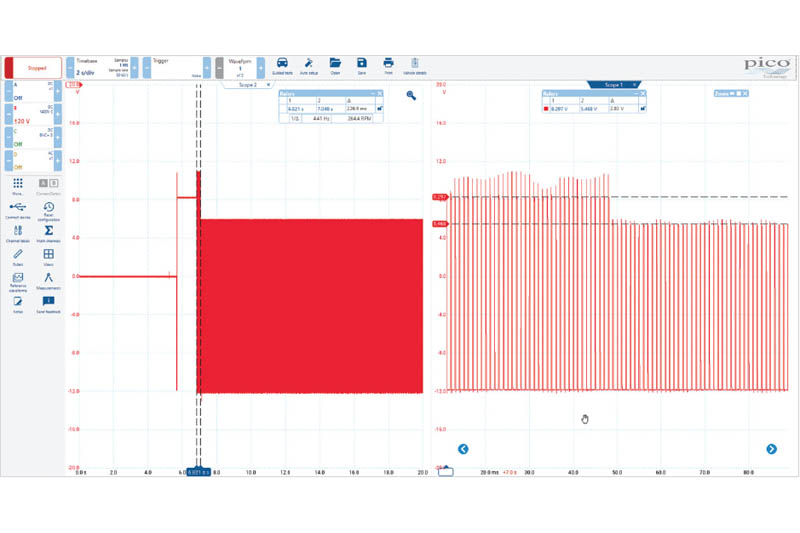

However, we then noticed that the EVSE clicked and the pattern from the CP dropped to the next step. I’m confident this isn’t expected behaviour but it makes sense, as putting the vehicle into ready mode closes the contactors. Removing the EVSE and then switching the ignition to on before reconnecting the EVSE gave us the pattern we were expecting (Fig. 5).

Adding a current clamp (as shown in Fig. 6) verified that current was indeed flowing. As expected with the ignition kept on and the charger connected, we can visually see that current is flowing from the mains to the OBC. After leaving it connected for a while, the battery SOC went up from 3% to 12% where the audible warning was no longer repeating and the range had also increased.

The customer was informed of where the testing had taken us and it was looking to be either a communication issue between the OBC and BMS. Either way, the contactors were not being closed when a charger was connected.

Final checks

There was further testing that needed to be carried out before being completely satisfied but, as customers sometimes do, they decided that they would take the information we had gained back to another garage where they then replaced the OBC.

We accept that this could well have been the case but no further diagnosis was carried out before the parts were fitted. If there are further tests to be carried out why wouldn’t you do them just for peace of mind, as what happens if it doesn’t fix the fault?

The OBC in this case didn’t fix the issue. One thing that none of us took into consideration was the battery lease program some manufacturers have in place. Whilst I knew about these programs, I had never worked on a vehicle with one and we should all be very aware of this when diagnosing EVs.

What I did not know was if the lease for the battery is not paid, the manufacturer can remotely disable the HV battery from charging, which is precisely what had happened to this vehicle. The current owner wasn’t the original owner and, when they had purchased the vehicle, that tiny piece of information regarding the battery lease was not fully explained.

This resulted in Renault remotely disabling the battery from charging with no warning given to the current owner. What I find strange though is there wasn’t any indication from the vehicle or the serial data to inform you that the battery had been disabled. From an aftermarket workshop view, if you had one of these turn up and were unaware that the batteries could be remotely disabled, it could cost you an awful lot of time and money.

As I mentioned at the beginning, please don’t use this as a training guide. I’ve purposely missed out connection drawings and some technical information with the hope that those wanting to diagnose these vehicles get the correct and approved training to do so.

Hopefully, this helps explain some of the new hurdles we have to face when working on electric vehicles. I also hope it inspires a new desire to learn more about how this new technology will affect our workshops in the future. Pico would like to think Daniel Mayo for helping with the challenge, and Peter Melville, HEVRA, for his continued technical support.

![Bosch outlines ESI[tronic] workshop software](https://cvwmagazine.co.uk/wp-content/uploads/2025/07/Bosch-ESItronic-25-165x109.jpg)