febi overviews the safety-critical nature of air springs and discusses its manufacturing process, which ensures the highest quality is achieved.

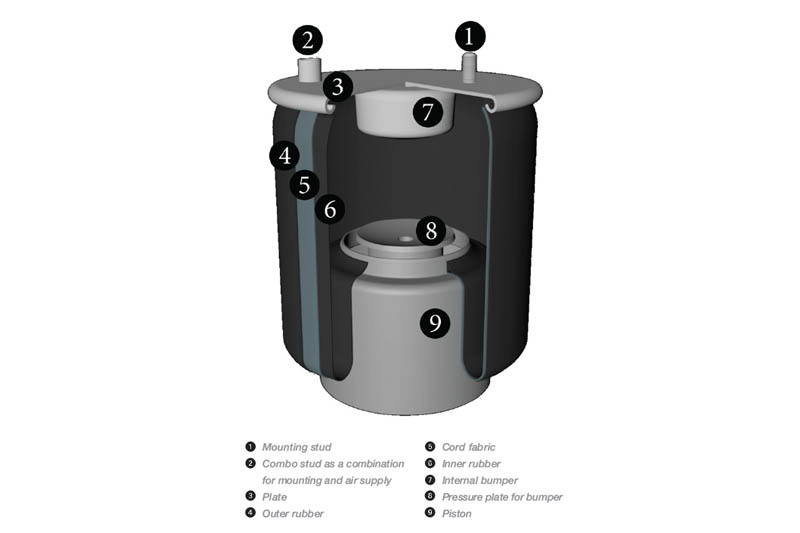

Air springs are placed between the axles and the vehicle chassis carrying the entirety of the vehicle’s weight. Together with the shock absorbers, they are responsible for driving stability and are a reliable and constant connection between the tyres and the road.

It is extremely important to keep the vehicle balanced and to transfer the wheel forces constantly during bends, braking, and acceleration. Besides these safety-critical tasks, the comfort of the driver and any sensitive loads being carried are also imperative. Due to variable pressurisation, air springs provide an adjustable spring rate, variable load-carrying ability, simplicity of height control and low friction. They are adaptable for light or heavy suspension applications.

The air spring’s ability to support a mass depends upon its effective area, which is a nominal area found by dividing the load supported by the spring and by the air pressure at any given position.

The spring rate is the result of the change in the effective area and the change in air pressure as the spring is deflected. The air pressure varies with the speed and magnitude of deflection; for a unit of deflection, the pressure – and, therefore, the spring rate – will be different for isothermal, adiabatic, or polytropic processes.

The rubber

The special rubber mixture of febi air springs ensures a good resistance against substances in the pressurised air – like oil mist and environmental influences on the outside of the air spring.

The recipe was developed over many years so it has the best properties for its intended purpose. The tensile strength of the rubber is tested to the maximum force until the rubber breaks. This ensures that only raw materials with the defined properties are used for production.

The cord fabric

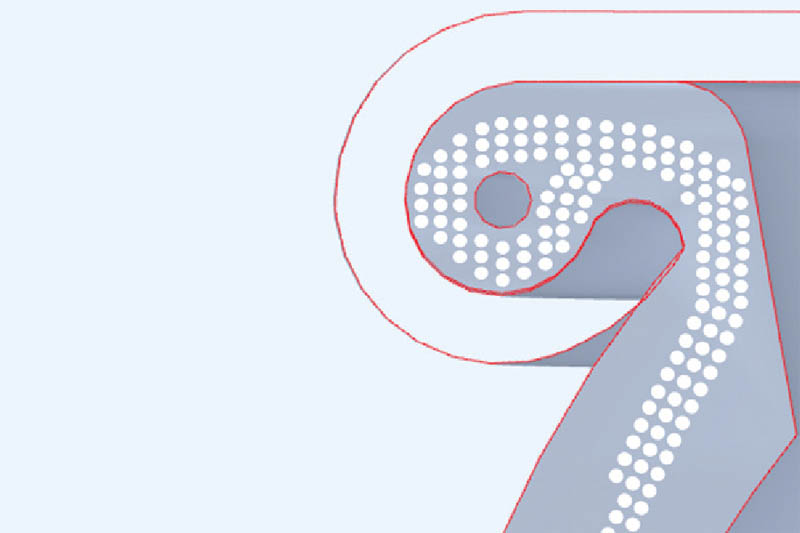

The cord fabric is used as a reinforcing element. Its woven structure gives the rubber the required strength and durability against pressure and other forces. Up to 3 reinforcing layers are used on some air spring references – such as in stressed areas with high demands on stability.

The fabric is made of a polyamide or a mixture of polyamide and aramid. It is placed between the outer and inner rubber layers. The positioning of the different rubber and reinforcing layers, as well as the manual or automatic wrapping process, is a key factor for durability and lifetime and is based on extensive experience.

Plastic or metal components

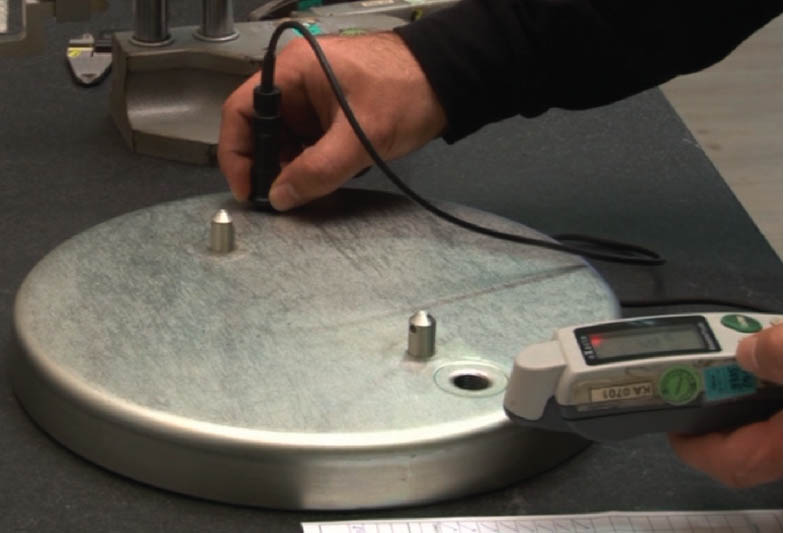

Since air springs are exposed to all environmental influences, the corrosion protection of metal parts is a constant topic. The material specification and hardness, as well as the corrosion protection coating, is tested constantly and has to be in accordance with defined OEM standards. Only approved parts where the functional dimensions are met with the high requirements are used in production.

Steam vulcanisation

There are different production methods in the air spring industry: vulcanisation with an electric heating mould or steam vulcanisation – or a combination of both. Steam vulcanisation is the better and state-of- the-art method.

While the electric heating mould is only “cooking” the air spring, steam vulcanisation is curing the material. This leads to a longer lifetime and durability of air springs. This is thanks to better vulcanisation and bonding of the different rubber and cord layers and consistent hardness of the complete rubber.

The steam is applied at different locations of the mould to heat specific areas where a higher temperature is needed for the vulcanisation – for example, where three reinforcing layers are applied in the area of the plate.

The production of air springs is anything but simple. It is all about controlling the time, pressure, and temperature to get the optimal vulcanisation result. The values of the production key factors are based on decades of experience.

Quality with confidence

To be sure that nothing goes wrong in the production process, air springs with plates and pistons are regularly checked by a simple, yet highly effective test. They are pressurised and checked for leaks in a water bath. Lights in the underwater area make even small bubbles visible.

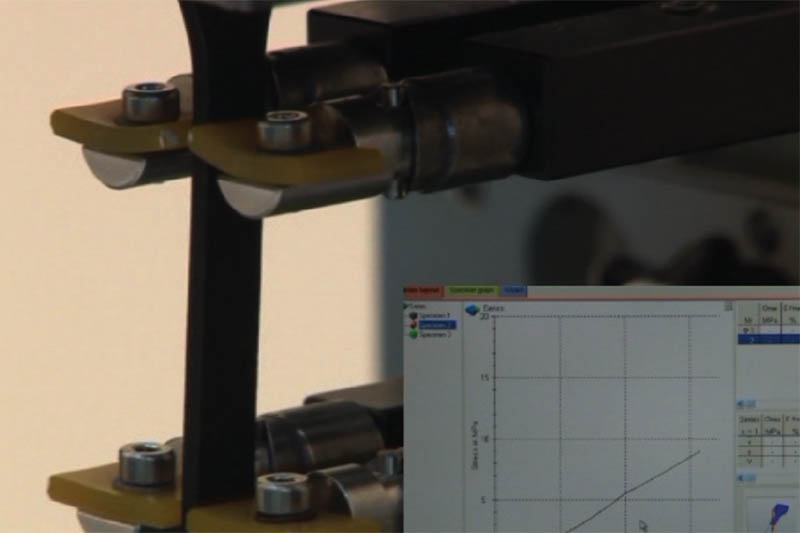

Lifetime tests are carried out frequently on a special test rig to ensure that febi air springs meet the OEM requirements. The air spring is mounted in a rocker construction and has to perform up to 3,000,000 load and unload cycles pressurised with seven bar.

The tested raw materials together with the perfected production and the state-of-the- art steam vulcanisation ensure that our customers get a reliable and durable product for a safe and long-lasting life on the road.

febi provide a wide range of more than 375 air springs covering common European truck manufacturers.