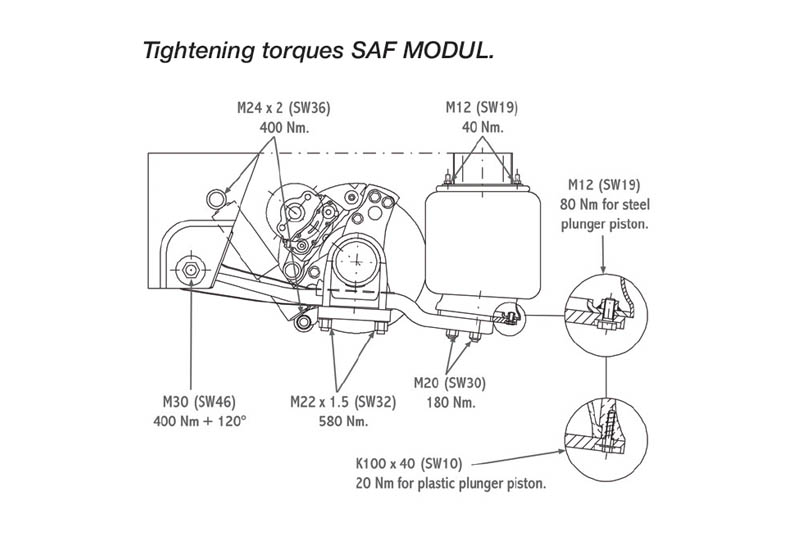

IMS runs CVW through its new shock absorber tightening torques for SAF Intra axles.

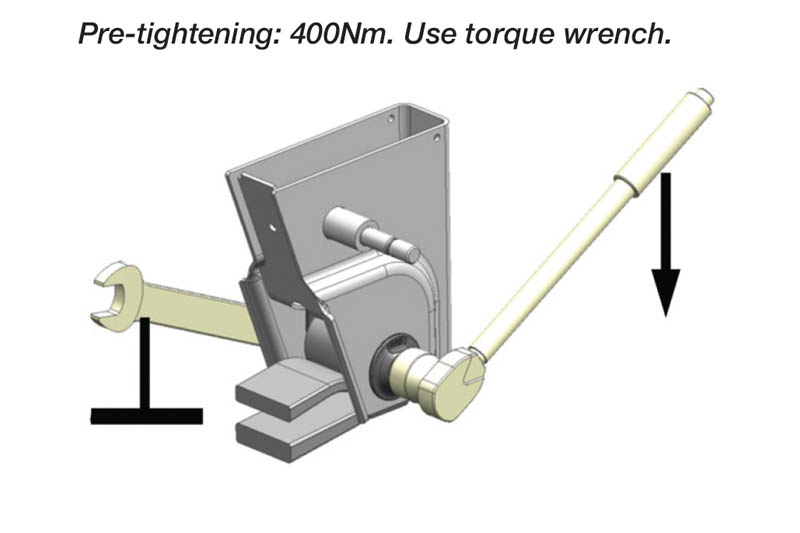

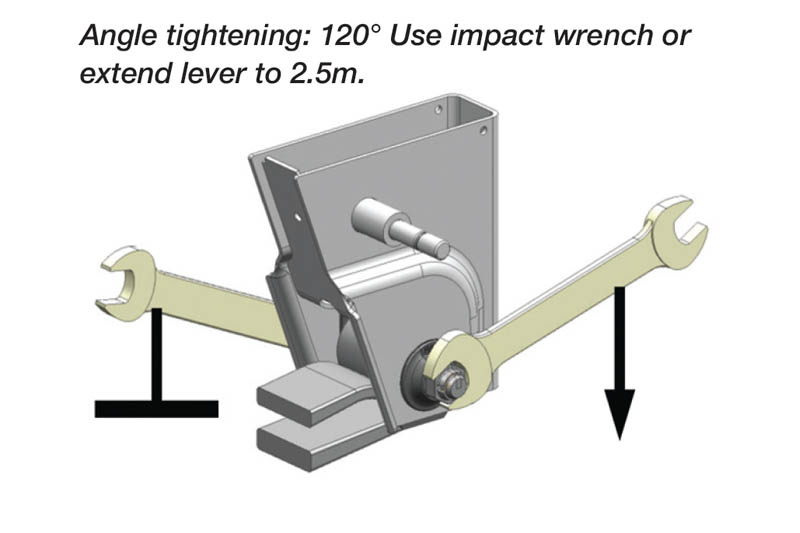

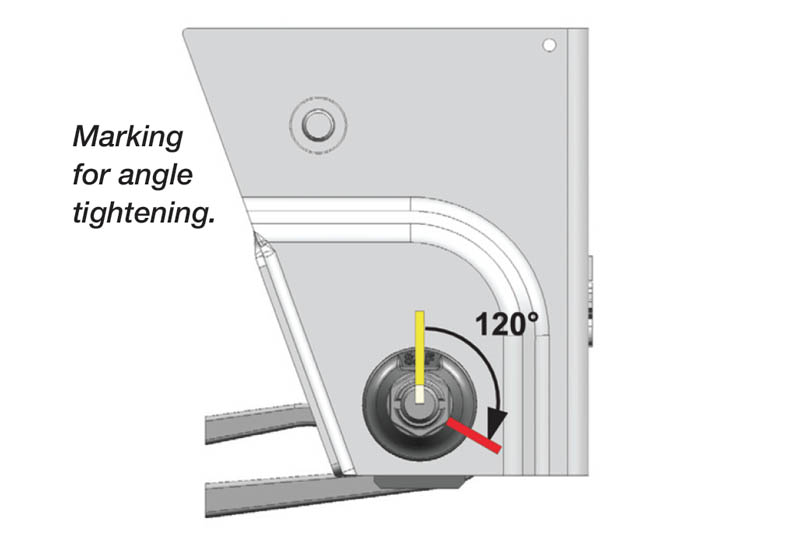

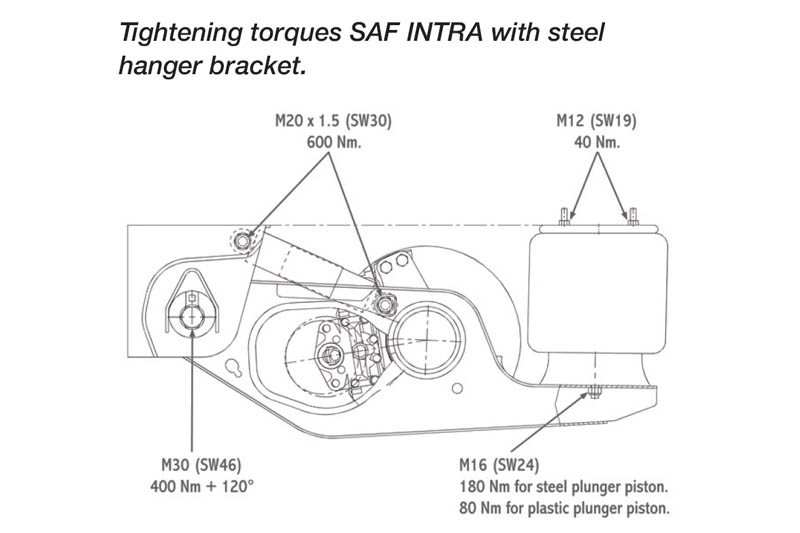

The pivot bolt on the Intra Suspension is maintenance free in combination with the steel hanger bracket providing the pivot bolt is torqued correctly (400Nm and 120°).

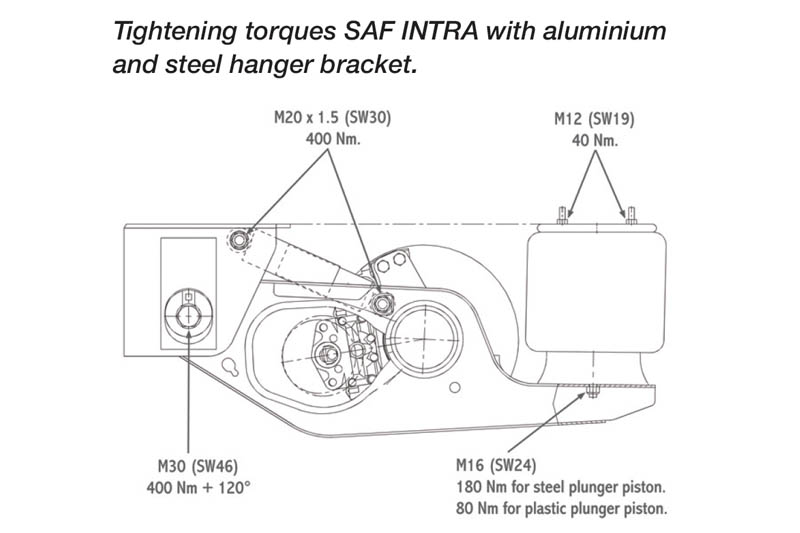

The aluminium and stainless steel hanger brackets requires a torque check at 500km and then every six months. The pivot bolts should not be reused as there are stretch bolts. Incorrect tightening of the pivot bolt can take place after wheel alignment, incorrect fitment from the trailer builder, incorrect torque or incorrect paint thickness.

It is vital that the bush it fitted correctly as otherwise it will not function correctly. Always replace the plastic wear sleeves as these prevent metal-to-mental contact with the hanger brackets.

It is vital that the bush it fitted correctly as otherwise it will not function correctly. Always replace the plastic wear sleeves as these prevent metal-to-mental contact with the hanger brackets.

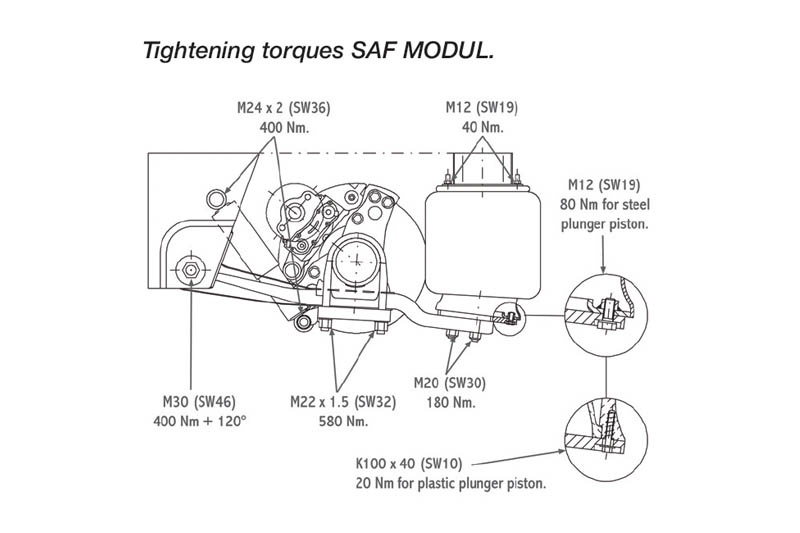

When tighten the pivot bolt, this must be done when the trailer is sitting at ride height otherwise the bush will turn when the suspension sits back at her ride height.

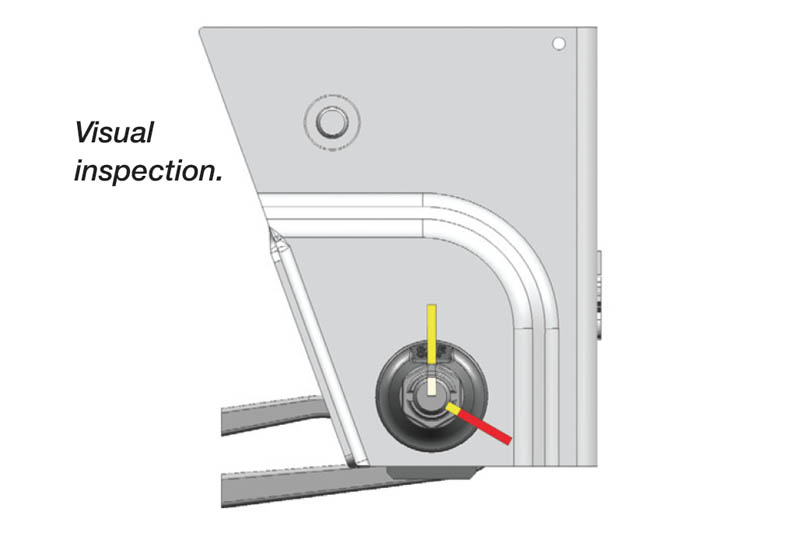

Shocker torque is 600Nm and should always be fitted with the (Top) marker pointing upwards as there is a valve inside the shock absorber because of the angle the shocker sits at.

Important things to remember

- Always tighten within the specified ride height range

- There must be no paint residue between the eccentric/thrust washer and hanger

- Threads must not be oiled or greased

- The pivot bolts on the steel hanger brackets are maintenance free

- Service intervals for aluminium hanger brackets and stainless steel hanger brackets – first check after 500km, then check after every six months

- Pivot bolt: inspection torque 1,200Nm

- Shock absorber bolt: inspection torque 600Nm