IMS, the exclusive distributor of SAF-Holland products in the UK, runs us through a step-by-step guide on how technicians can identify issues that stem from different braking systems.

The IMS Service Engineering Team regularly gets asked by customers to help with the identification of trailer braking system-related problems experienced when the vehicle is in service on the road. The case below is commonly reported across a range of different braking systems. The checks outlined are appropriate for a number of problems, such as overheating brakes, poor braking performance and excessive lining/pad wear.

This simple guide is designed to help technicians troubleshoot some of the problems they are most likely to come across.

Modern tractor/trailer combinations have advanced braking electronics. Real-life dynamic testing helps to provide a clearer picture of the harmonisation between tractor and trailer. Brake temperature testing is an easy way of determining just how effectively the tractor and trailer are working together. It is recommended that tractor/trailer synchronisation/brake adjustment tests are undertaken on a regular basis to ensure that the combination operates safely and efficiently.

For the results to be meaningful, the vehicle should be tested under normal, dayto- day operating conditions. Run the tractor/trailer combination on the road for no less than 30 minutes before commencing tests.

Temperature measurement should be taken as soon as possible after the vehicle arrives at the workshop. The parking brake should not be applied, but most importantly, full safety procedures must be observed to secure the vehicle by chocking the wheels. Record the temperatures.

Make sure that the configuration of the foundation brakes complies fully with the brake calculation, referring to manufacturers’ specifications as necessary.

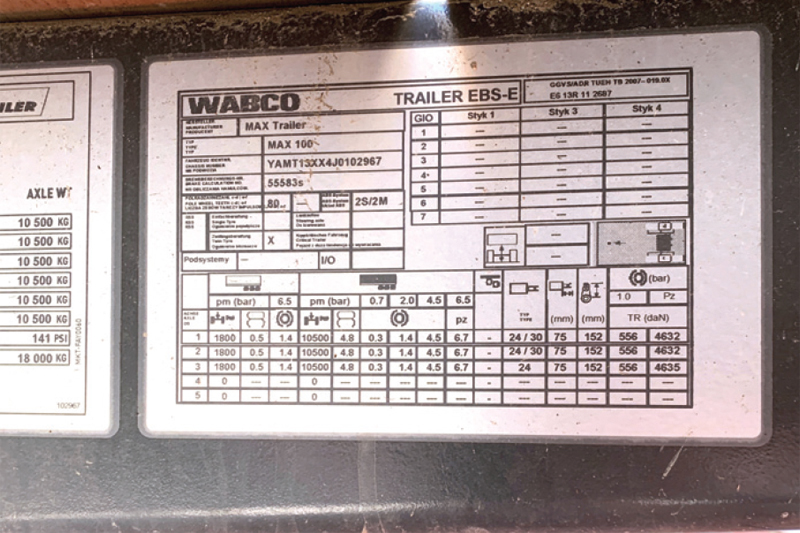

The manufacturer’s recommendations can also be obtained by reviewing the axle specifications. Locate and note the relevant information on the axle serial plate.

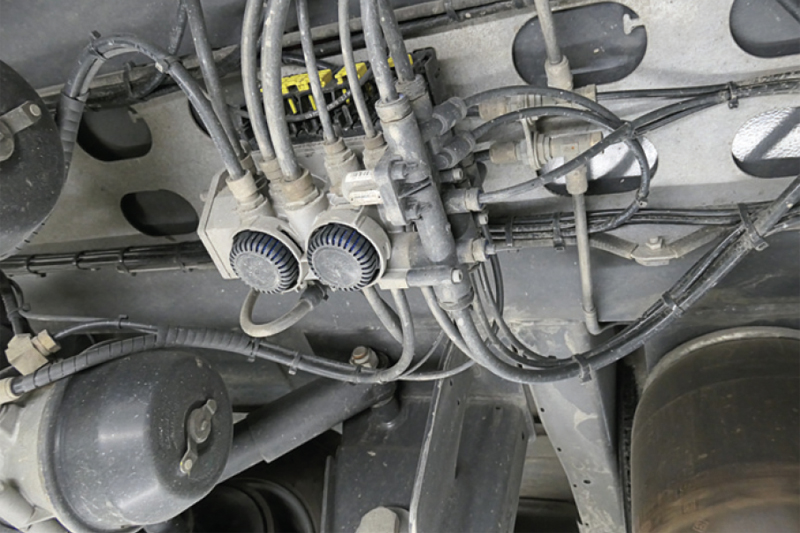

Next, connect up to the EBS unit.

Next, connect up to the EBS unit.

Access the EBS data parameters, and check to make sure that these are in line with the brake calculation and foundation brake specifications.

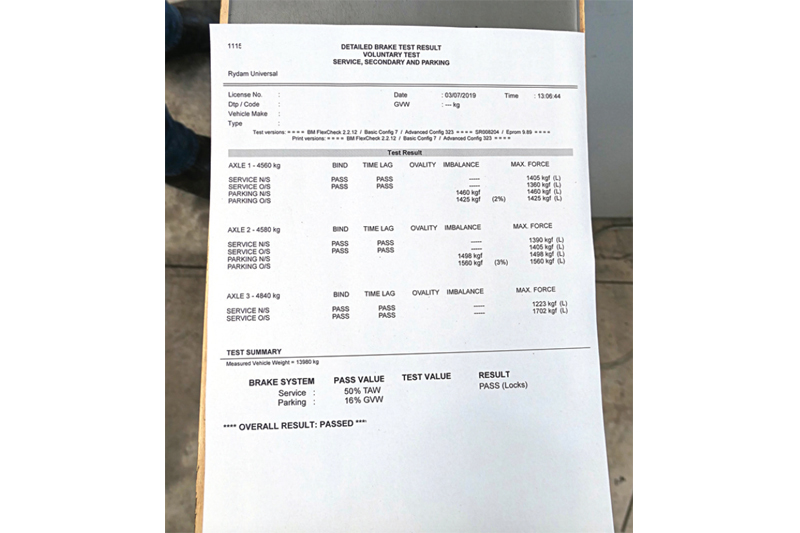

Conduct a rolling brake test and record the findings.

Once all of the necessary data has been gathered, share it with both the EBS supplier and axle manufacturer to help identify the cause of the problem and to determine the best course of action to resolve it.