Trailer wheel alignment is often overlooked says Russ Coad, managing director, AES UK, but the gains in tyre performance and cost make it worthwhile.

It is estimated over 50% of trailers on UK roads are out of alignment, with fleet operators often focusing on tractor units and overlooking trailers due to the nature of how they’re exchanged. AES believes there are enough benefits to be had for larger fleets to consider corrective wheel alignment on trailers including:

- cost savings – up to 15% savings on tyres costs with correct wheel alignment

- fuel savings – a correctly aligned trailer can reduce the pulling force (drag) on the towing unit lowering rolling resistance

- safety – misaligned trailers often take up more room on the road due to ‘dog-run’ or ‘crabbing’ that can create uncomfortable and unsafe handling behaviour for the driver

- environment – fuel and tyre cost savings reduce your CO2 emissions and tyre dust pollution

Example trailer tyre costs saving

Avg. super single tyre cost £300

Avg. mileage of super single 200,000 miles

Avg. annual driven miles 100,000 miles

Avg. no. of tyres on trailer 6

Fleet size 80 Trailers

Potential annual tyre cost savings £10,800

Cost effective

As an example, using data from the Department for Transport study (see below) AES has created an example of tyre cost saving for correctly aligned trailers versus incorrectly aligned trailers.

Though AES recommends annual proactive alignment checks on trailers, some fleet operators don’t have the luxury of being able to for whatever reason. If that is the case, we’ve outlined some pointers that could indicate issues with trailer alignment:

- tyres – premature tyre wear, blow-outs and damage to trailer tyres. Premature wear on the towing unit

- crabbing / dog-run – driver complains or observable crabbing on a trailer

- instability – driver complains of bad driving behaviour such as pulling or additional drag beyond the norm

Corrective procedure

Wheel alignments on trailers can be carried out by trained contractors or through owned equipment, such as Josam alignment systems, which can measure all types of trailers and provide a detailed before and after report within the software, which also offers a tyre management system to monitor tyres alongside wheel alignments.

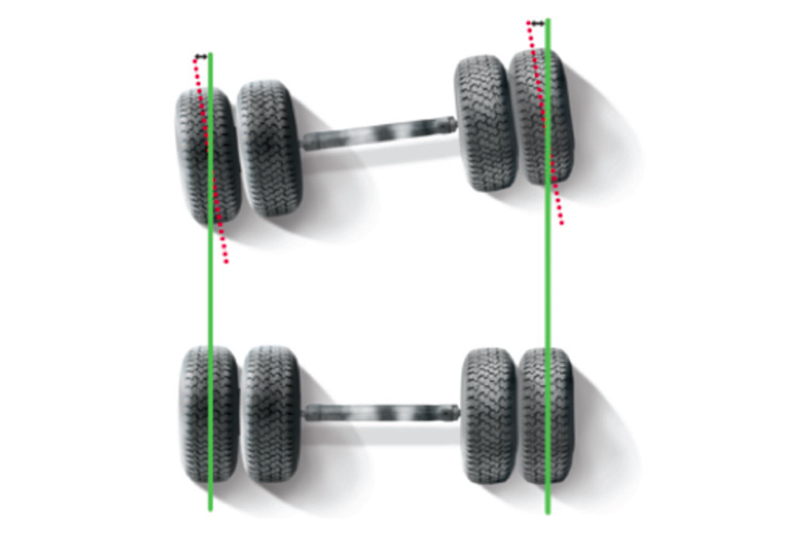

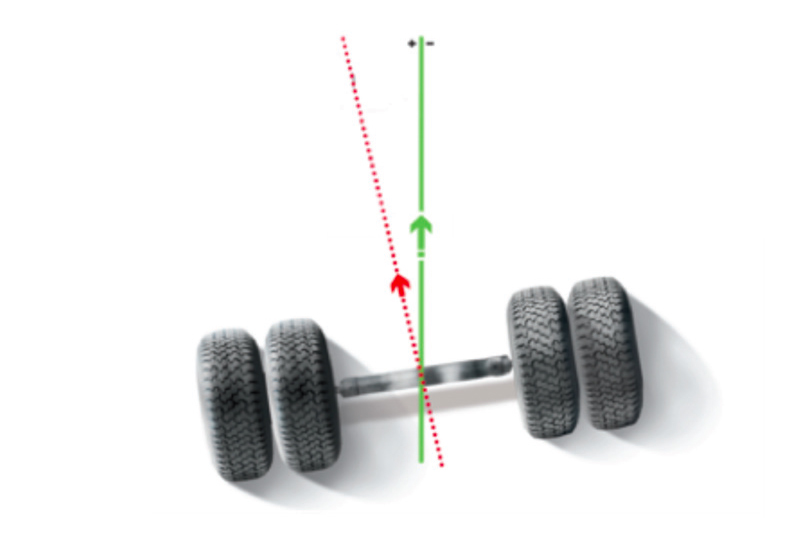

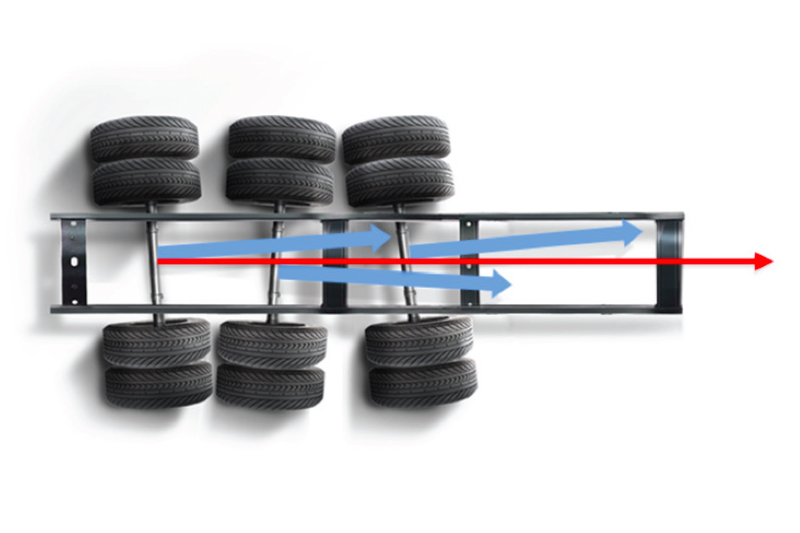

When measuring a typical trailer with three non-steered axles there are two main measurements to look for – out-of-square and parallelism. Out of square is the angle of the axle in relation to the centreline and parallelism is the angle of two or more axles in relation to each other.

Right is an example of a 3-axle trailer with each axle having largely unique out-of-square axles in relation to the centreline. As you can imagine there would be increased tyre wear and drag on the towing unit.

In this particular example, depending on the OEM tolerances, each axle would have to be adjusted to bring it within tolerance in relation to the centreline, only adjusting one axle would have minimal impact.

Keeping trailers on the straight and narrow

A wheel alignment case study performed by the Department for Transport, using Josam equipment, performed in the early 2000s highlighted that a 0.5° misalignment can reduce tyre life by up to 50%.

A Lancaster-based company that employed 30 drivers and ran a 12-hour operation from Monday to Friday at the time of the study, with a that fleet consisted of 80 semi-trailers plus other vehicles. The company, running trailers on super single tyres, observed a 15% increase in super single tyre life on their trailers reducing costs significantly.