How to overcome the ADAS skills gap

With systems such as ADAS on the increase, are there enough technicians around to work on them? Gareth Newbery, national sales manager, Repairify offers ways forward.

Over the last few years, the number of ADAS systems within vehicles has dramatically increased as this technology now comes as standard on most vehicles that come off the production line. This means that the number of vehicles that will require calibration will continue to increase. But will the industry be able to handle all this work? Currently, according to the latest data from the IMI’s ADAS TechSafe technician forecasts, the industry would require 18,000 technicians to meet current ADAS requirements. However, if we look at the actual number of qualified technicians there are currently only around 3,500.

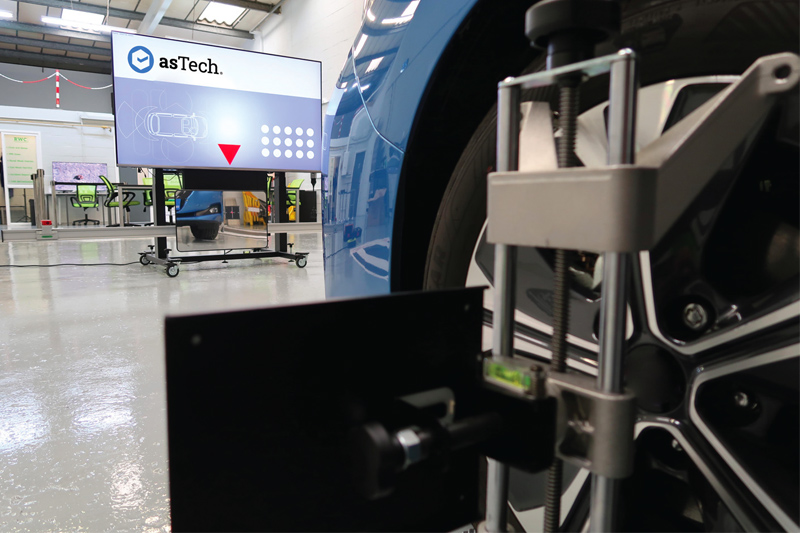

We know this is a huge challenge to overcome but it is where companies such as Repairify are important. Our proprietary technology provides services to diagnose, calibrate and program systems remotely supported by our IMI-trained technicians, who will assist where organisations don’t have such resources locally to do the work. In addition, our growing global solutions include access to the development of AI and machine learning to enhance our data, enabling us to ensure information and solutions are available at the right time in the workflow or shop processes, providing customers with the ability to have critical repair information at their fingertips.

Alongside using third parties to do the work, there are ways in which businesses can help bridge the gap. This is done through apprenticeships and training programs that are supported by the apprentice levy and various support schemes that are available. We are also seeing businesses investing in their apprenticeship and training programs. This is a positive step because they understand the benefits it will enable them to reap in the short, medium and long term. As a business, we are also committed to investing in training programs both internally for our team and externally for our customers. This is because we understand in no uncertain terms that it will assist in providing our team and the industry with the skills that are needed to keep pace with the work hitting the workshop floor and the knowledge to understand the technology within the vehicles that are coming off the production line.

The industry will be able to handle the expected increase in the volume and complexity of work, but this will come with tough challenges that must be overcome. It also offers opportunities to operators who adapt early to the ever-changing environment. The correct implementation of technology to complete calibration and diagnostic work efficiently with trained technicians, who have the skills and experience to complete the job the first time, is what is required to bridge the ADAS skills gap. In addition, the operators that adapt the quickest will see several benefits that include streamlining operations, reducing overheads by keeping work in-house and reducing key-to-key times. When it comes to the cost-saving efficiencies, they can be reinvested in more tools, training and staff or site expansion to meet the growing demands for ADAS calibration.

Overall, we know the ADAS skills gap is real but with the right investment in tools, training and apprenticeships the sector can slowly start to fill the requirement for technicians needed to handle the amount of work relating to ADAS that is hitting workshop floors now and in the future.