How to maintain air suspension

BPW talks CVW through its air suspension options for 9-tonne axles and the maintenance regimes associated with them.

BPW air suspension systems are designed to deliver reliable performance across various trailer applications, whether for curtainsiders in long-distance haulage, tanker trailers in distribution or tipping trailers in quarries. These systems are designed to adapt seamlessly to varying road conditions while maintaining a strong focus on efficiency.

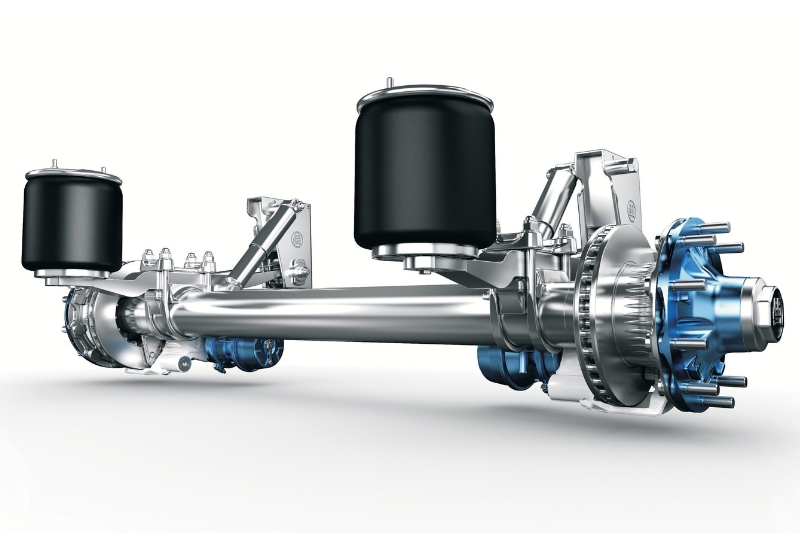

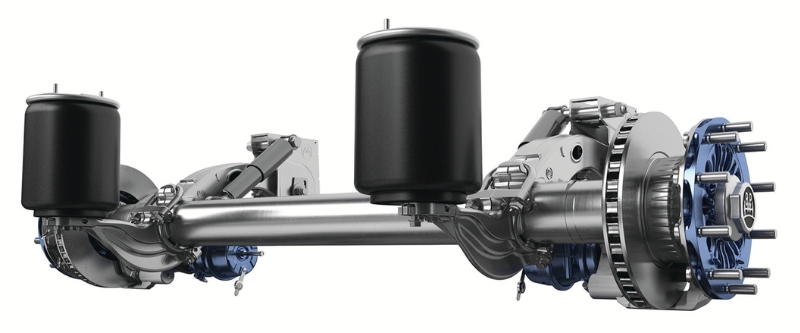

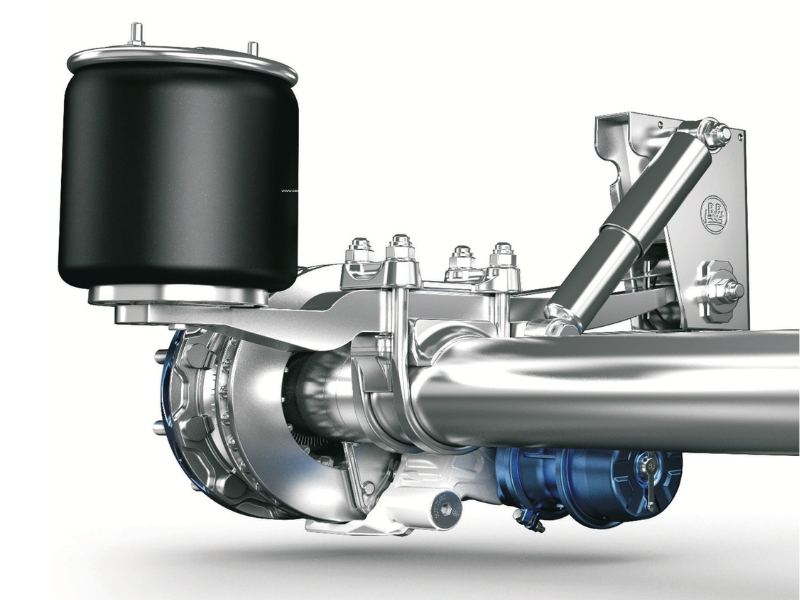

With a modular design that simplifies servicing, BPW offers two types of air suspension for 9 tonne axles: the conventional sprung steel trailing arm of the Airlight II, Airlight II Round, and Airlight Heavy Duty (AL-HD), and the cast trailing arm of the Eco Air.

Air suspension maintenance very often receives cursory attention within the statutory periodic inspection cycle. However, it is an important sub-assembly and is responsible for connecting the trailer chassis to, and distributing the load onto, the axle.

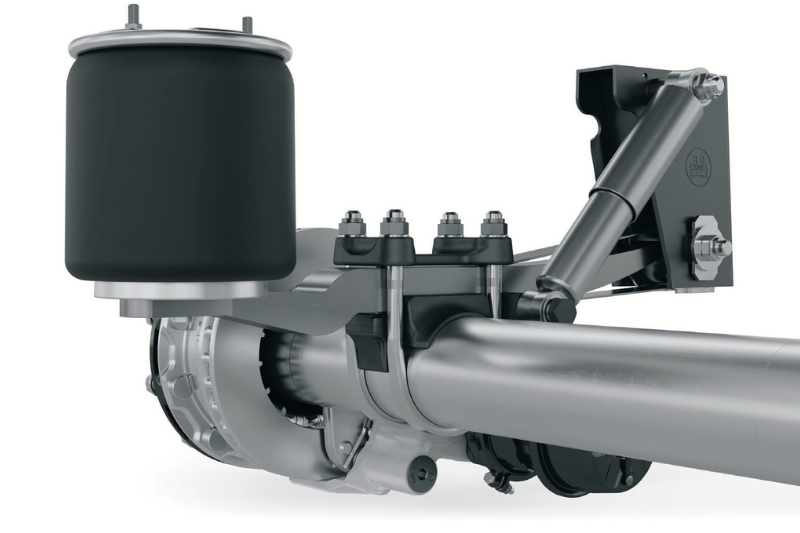

It must also be remembered that in an air suspension system, the axle beam is an important component of the suspension system. The connection between the axle beam and the trailing arm is key to the performance of the suspension. BPW supplies assembled axles and suspensions to trailer builders. This enables the company to include, within the five-year warranty (three years for vehicles that travel off-road), both U-bolts and spring seats.

First principles

Both suspension systems provide the same physical properties, allowing BPW to offer solutions to cater for different types of trailer design and operating conditions. In order to understand the maintenance requirements of an air suspension, it is worth spending a little time understanding the principles of the operations. The suspension system on a vehicle comprises the tyres, air bags, trailing arms and bushes. It allows relative motion between the trailer chassis and the road whilst still providing support.

The suspension system contributes to the vehicle’s road-holding and braking performance to ensure that the trailer’s payload is given the best possible ride quality.

The design of a suspension system is generally a compromise, and this is more so with a trailer where the difference in ground weight varies so much between unladen and fully laden. It is really important to ensure that the tyre is kept in contact with the road at all times, as this is all that gives the vehicle its braking adhesion and lateral stability.

In terms of maintenance, the regime is quite straightforward and involves periodic inspection for wear and damage and checking the security of the fastenings. The air bags contribute very little to roll stability (around 7%); stability is mainly provided by the axle beam and the two trailing arms which combine to form a large U-shaped anti-roll bar.

It is essential, therefore, to ensure that the U-bolts are kept tight. Different types of suspension have different sizes of U-bolts and different requirements for torque settings and methods of checking. BPW service manuals give the procedures for the different suspension systems that it produces. The presence of corrosion around the interface between the spring saddles and the axle beams is a tell-tale sign that the assembly is loose, and attention is required to prevent further secondary damage to the axle beam from movement between it and the spring saddle.

Torque settings

The U-bolts on the suspension systems Airlight II, Airlight II Round and Eco Air are designed to stretch when tightened to the correct torque setting. If disassembled, the U-bolts must be replaced along with the nuts and washers. It is essential to use the correct tightening method settings on all U-bolts.

During a trailer inspection, it is important that a workshop technician can accurately identify the type of suspension fitted to the trailer. Once established, the correct ‘checking torque’ should be used to ensure that the clamping force of the components remain uncompromised.

Air bags

Air bags need to be inspected for damage, leaks, and perishing; this is best done during the statutory periodic inspections. The air bags are made of rubber which naturally starts to age immediately after the manufacturing process is completed. In recent years, legislation has dictated that ageing additives comply with the new directives, and this has shortened the life of air bags.

Perishing manifests on the roll of the air bag where the rubber rolls under, adjacent to the piston, therefore particular care should be given to inspections in this area. Look at the piston for signs of damage from stones, contact with kerbs, or loading bay reversing guides. If the ride height of the suspension is incorrect, or if the trailer has too much slope, then this will cause the air bags to either stretch out or ride on the internal bump stops. Either of these situations will cause damage.

Trailing arms

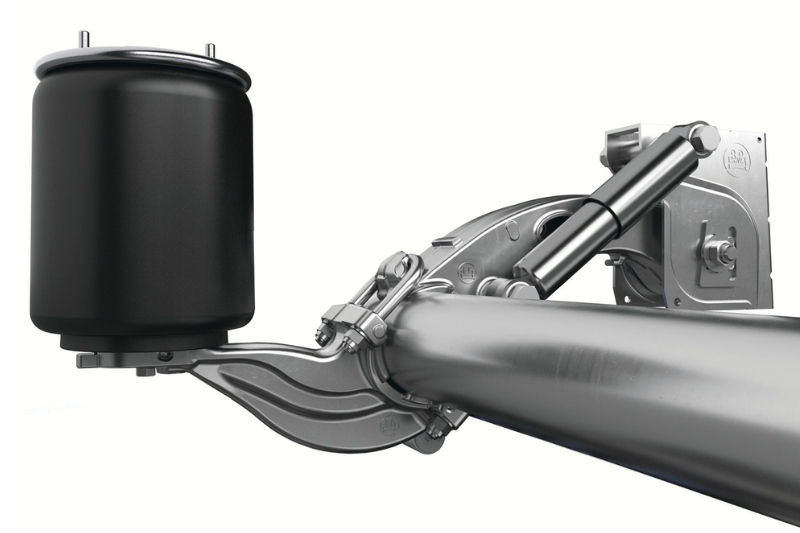

Trailing arms need very little attention, save to check for damage. Where single leaf trailing arms are used, BPW fits a catch plate. This is a strip made from galvanised steel that encompasses the trailing arm and is trapped under the spring plates in the area of the U-bolts. If a trailing arm breaks, the catch plate will hold the axle in place until the vehicle can receive attention in the workshop. This will prevent the tyres and air bags from being damaged due to the axle becoming grossly misaligned.

The catch plate should always be replaced in order to maintain this safety feature. Any detritus that has built-up between the catch plate and the trailing arm should be removed periodically. Dirt build-up in this area will encourage dampness, which will eventually corrode the top of the trailing arm, leaving it vulnerable to breaking. The rubber bush in the eye at the front of the trailing arm gives little trouble. It can be checked by attempting to move the trailer with the brakes on. There should be no more than 2 or 3 mm of movement between the trailing arm and the hanger bracket in the Airlight II suspension.