What’s the role of slack adjusters?

Febi delves into everything about slack adjusters, a safety relevant part that is often overlooked.

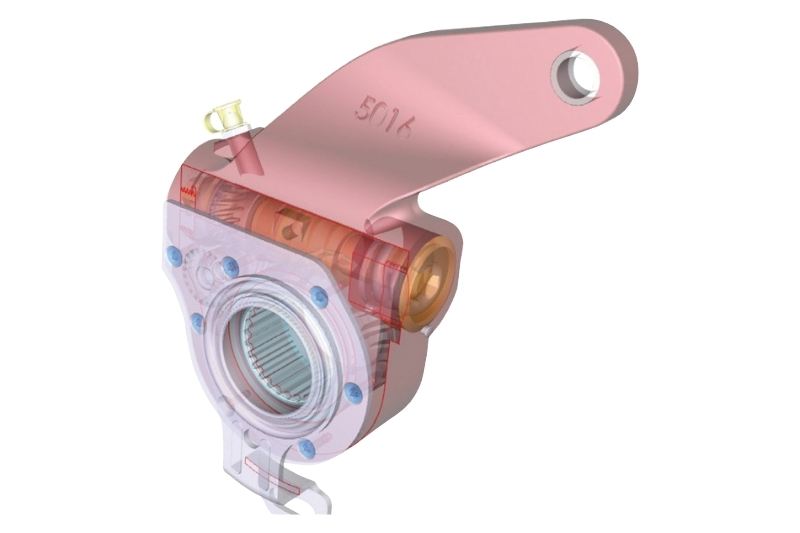

In air brake systems of commercial vehicles, slack adjusters are used to compensate the brake-related wear of brake linings and brake drums in the drum brake and ensure a constant clearance between these components.

Slack adjusters are used with S-Cam drum brakes and take over the transmission of the braking force from the brake cylinder to the S-Cam shaft. This enables manual or automatic adjustment of the S-Cam shaft so that the brake cylinder operates in approximately the same stroke range. A heavy vehicle with a total weight of up to 40 tonnes requires an enormous amount of force to be applied by the air brake system in order to avoid dangerous situations. Slack adjusters take on the task of applying the air brakes by keeping the brakes adjusted and in the right balance.

Automatic vs manual

Automatic slack adjusters, or ASAs, also called automatic brake adjusters, are a luxury these days. Few drivers can remember what it was like before they existed. In the old days, when there were manual slack adjusters, drivers had to crawl under the axles of tractors and trailers to adjust the brakes by taking a spanner and adjusting the travel of each push rod on each slack adjuster. To avoid accidents, they had to check and readjust this every day, especially in heavy traffic and difficult terrain, such as in the mountains. Now there are automatic slack adjusters on every axle with drum brakes, and the slack adjusters adjust automatically while driving. They have been mandatory for trucks and tractors since 1994 and for trailers since 1995.

Nowadays, more than 90 per cent of all trucks with drum brakes in western countries are equipped with automatic slack adjusters. For trailers, this percentage could be significantly lower, as the regulation was introduced later and trailers remain in the fleet much longer.

Slack adjuster maintenance

Slack adjusters that are not being greased regularly during scheduled maintenance and inspections have a direct impact on both safety and regulatory compliance. Lubricating the slack adjuster serves two important purposes: Pressing in the new lubricant forces out the old grease along with water and contaminants that have entered the inside of the slack adjuster and it protects the internal gear sets, clutches and other components of the slack adjuster from wear. Both are necessary for the slack adjuster to function properly, to ensure the correct braking distance and enable optimum braking performance. febi recommends lubricating the slack adjusters with NLGI grade 2 long-term grease at every preventative maintenance inspection. However, no sulfide-containing lubricants may be used.

Top tips!

- Do not manually adjust automatic slack adjusters after initial adjustment unless you are doing a complete brake overhaul.

- Never use an impact wrench to adjust. If you do, internal slack adjuster damage may occur.

- When re-lining brakes, remove the slack adjuster from the S-cam. Then rotate the worm wheel 90˚ before refitting. This reduces uneven wear.

- Make sure that the adjustment arm is always firmly connected to the bracket.

Note: An automatic slack adjuster only needs to be manually adjusted during initial installation or when replacing brake linings and/or drums. Manual adjustment may also be necessary in emergencies when the air pressure cannot release the brakes. However, this should only be carried out by a certified technician!

Uneven braking with automatic slack adjusters?

If you discover uneven braking or excess pushrod travel on your vehicle, try to correct it by applying a few service brake applications to automatically adjust the brakes. If that does not work, have your brakes inspected immediately by a certified and knowledgeable technician. If the automatic slack adjuster does not bring pushrod travel into normal limits and you know there is no underlying brake issue causing it, always opt for replacement of the automatic slack adjuster.

Brake parts are safety relevant

Not only should the slack adjusters be checked regularly for tight fit, function and wear, but also the surrounding components. If there is any doubt about the correct function of slack adjusters, they should be replaced. For safety reasons, the replacement of brake parts and work on the brake system should only be carried out by trained specialists.

When slack adjusters need to be replaced, always choose high quality parts. The tested, high-quality slack adjusters from febi in OE matching quality are said to be the safest option and cost less than low-quality products in the end.

Rely on tested OE matching quality replacement parts from febi. The entire braking range can be found at: WWW.RDR.LINK/VBS001. The febi brand is part of the bilstein group, the umbrella organisation for several other strong brands.