Febi investigates a common fault that can be found in air tanks and a common fault in oil separators.

AIR TANKS

Function

Many important and safety-relevant systems in commercial vehicles are operated with compressed air, such as the air suspension, the transmission control, or the brake system. To make sure the necessary operating pressure is always available, the compressed air must be stored. The air storage in the air tank makes it possible to use more air than the air compressor produces for a short period of time.

Cause of failure

Seams that have not been properly welded can suffer from air leaks or can even experience bursting. The material used also plays an important role: only the use of high-quality steel with a certain yield strength ensures safe operation.

The surface coating plays an important role in preventing corrosion on both the inside and outside of the air tank. If the protective paint layer is too thin or damaged, rust can easily take effect. The service life of the tank is then reduced and the risk of leaks increases – even with the possibility of bursting.

OIL SEPARATORS

Function

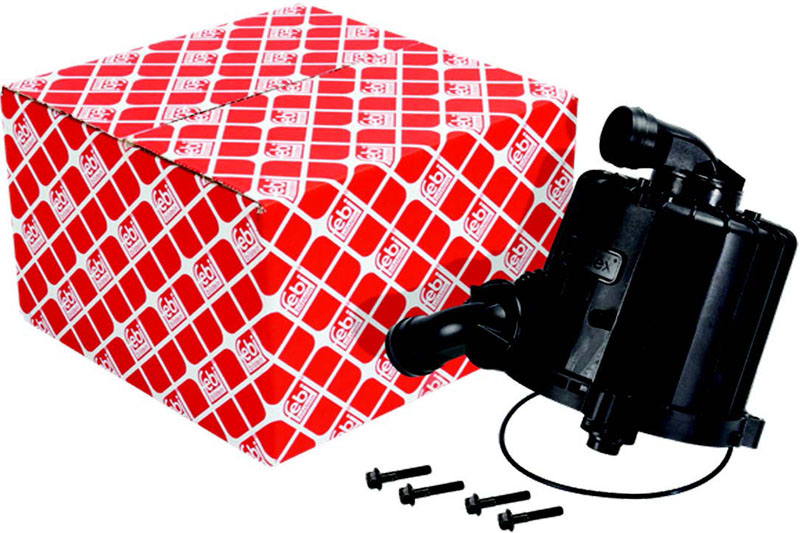

In piston engines, the combustion process in the cylinder unintentionally creates excess pressure in the crankcase. To reduce this pressure, a venting process must take place somewhere in the engine. This is done by a crankcase ventilation with oil separation. So-called centrifugal oil separators, such as febi 171457, are often used.

They separate the oil – which is part of the gases in the crankcase in the form of oil mist or droplets – by means of a rapidly rotating conical disc stack. The separated oil then flows back into the oil sump and the remaining gases are fed into the intake area of the engine.

Cause of failure

Centrifugal oil separators operate at speeds of 7000-9000 rpm. The tapered disk pack is mounted on a shaft which is supported by two ball bearings. If these ball bearings are worn out, the after-running of the centrifugal oil separator can be noticed by humming noises of the defective ball bearings after switching off the motor. If the oil separator is not replaced; the intake area can be heavily contaminated with oil by unfiltered crankcase gases.