Liftmaster details king pin press

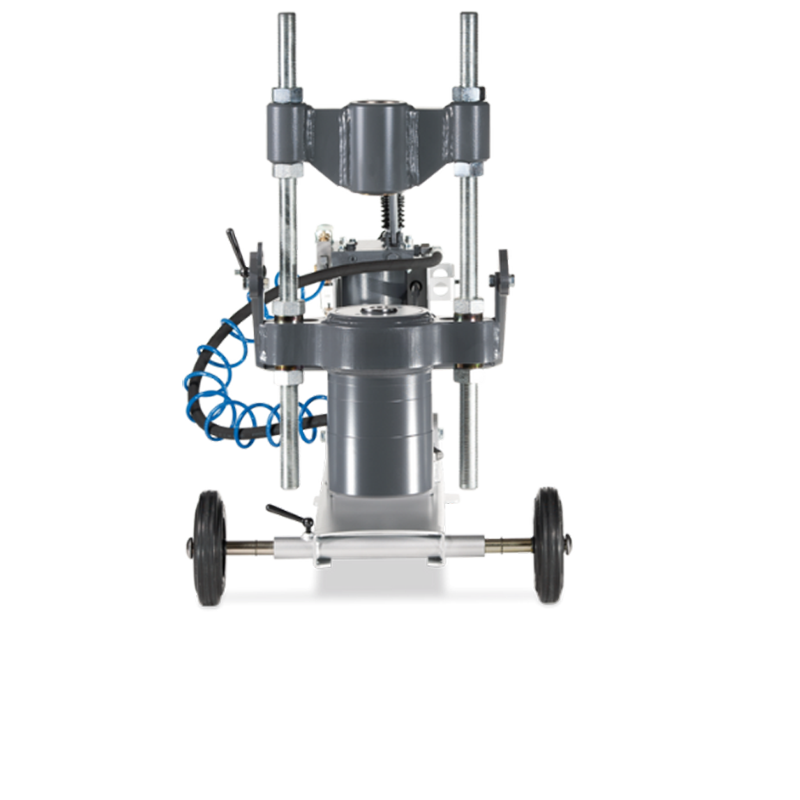

CVW takes a closer look at Liftmaster’s BP 65-215 King Pin Press.

Liftmaster have spent decades supplying the very best in workshop equipment. From quality lifts, brake testers and even specialist tools, to help you get the job done efficiently and safely.

The BP 65-215 S3 King Pin Press is one of those rare tools – a solution built to meet the rigorous demands of commercial vehicle workshops. Purpose-built for the safe and controlled removal and installation of king pins, bushings, and wheel bearings, it’s a press that makes heavy-duty work feel effortless. Robust, adaptable, and engineered to the highest standards, the BP 65-215 S3 isn’t just a tool – it’s an investment in speed, safety, and workshop innovation.

What is it – and what does it do?

The BP 65-215 S3 is a 65-tonne mobile king pin press, built for use in truck and bus maintenance workshops. Thanks to its electro-hydraulic system, this press delivers massive force, making light work of tasks that once required brute strength and an uncomfortable level of risk. It operates with a double-acting cylinder, giving users complete control during both pressing and retraction. This makes it ideal for working on commercial vehicles where access is limited, tolerances are tight, and downtime is costly.

The problem with traditional methods

Let’s be honest – manually removing king pins isn’t just frustrating. It’s dangerous. Technicians are often left battling with sledgehammers, heating tools, and improvised setups. Not only is this timeconsuming, but it’s also inconsistent, unsafe, and often damaging to surrounding components.

The BP 65-215 S3 removes the need for all that. It takes the guesswork out of pressing, providing a safe, repeatable, and efficient solution your team can rely on.

Why choose the BP 65-215 S3?

Workshops across the UK rely on this unit for one simple reason: it delivers. Here’s why:

- Unrivalled mobility – the unit can be wheeled directly to the vehicle, avoiding the need for disassembly or unnecessary lifting.

- 65 tonnes of pressing power, making it suitable for even the toughest applications.

- A modular design, allowing it to adapt to a wide variety of axle and bushing types.

- Easy operation, with an intuitive control panel and consistent pressing speed.

- But beyond that, it’s the peace of mind that sets it apart. Your team can focus on the job, not the tools – knowing the BP 65-215 S3 has the muscle to get it done.

The BP 65-215 S3 King Pin Press represents the kind of innovation we champion: engineered strength, backed by thoughtful design. If you’re looking to reduce vehicle downtime, protect your technicians, and bring your workshop operations in line with the demands of modern fleet servicing, the BP 65-215 S3 is a press that earns its place on your floor.