CVW speaks to a Scottish haulage company to understand how a new Tyre Pressure Monitoring System (TPMS) from Conti Tyres has led to significant savings in on-road incidents and downtime for the business.

Scottish haulier, Smith of Denny, had the opportunity to trial the new Continental Tyres ContiConnect portal and Yard Reader Station ahead of its introduction to the UK market. The system, which has now been launched, automatically reads and logs tyre pressures and temperature from all trucks and trailers leaving and entering an operator’s yard. Smith’s Director, Andrew Smith, says the system provided utmost accuracy on the company’s 26 trucks and 50 trailers, and helped reduce truck downtime.

Andrew commented: “We fit CPC sensors to all our tyres, so the Yard Reader Station works across every vehicle we run, and results have been very accurate from day one. Based on tyre life and the impact on safety and fleet performance, it’s an investment delivering worthwhile returns.”

“The biggest gain is the prevention of cost and elimination of downtime. Now, whenever a truck leaves the yard, we have the information we need to make instant decisions that can prevent a complete tyre failure, save on lost performance from poorly inflated tyres, avoid blow-outs and the ensuing critical downtime. We can spot things drivers can’t, such as slightly low inflation levels or indications of a slow puncture, and, if they have already left the yard, we can get in contact with them to immediately alert them to any actions they need to take.”

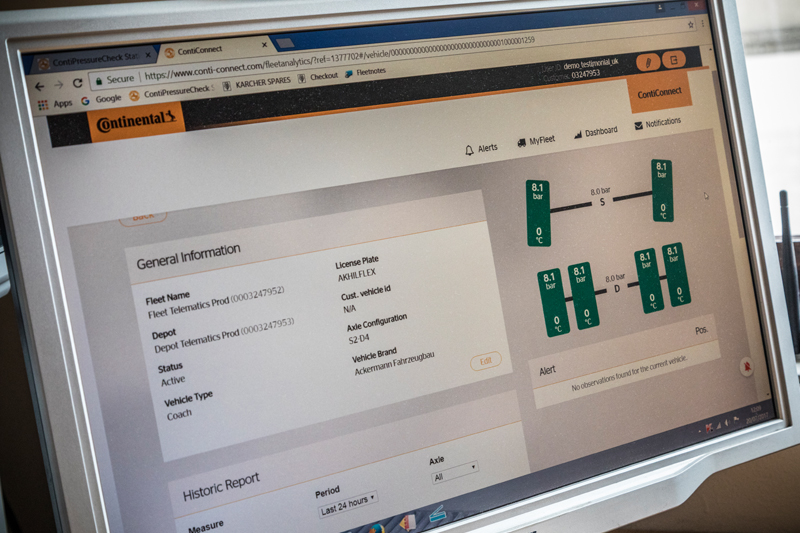

The discrete wall-mounted Yard Reader Station is fixed into the yard, and receives information from each tyre sensor as a truck and trailer passes. It links directly to Continental Tyres’ online management portal, ContiConnect, via GSM, where readings are displayed on screen to flag any problems to the operations manager, using a simple green/red colour-code against each tyre. Alerts can also be sent via text and email to make users aware of issues.

To communicate with the Yard Reader Station, any brand of tyre can be easily fitted with a CPC sensor, mounted on the tyre inner liner inside rubber housing. This ensures continuous measurement of tyre pressure and temperature beneath the tread, at the tyre’s contact point with the road surface.

The new software gives operators an accurate snapshot of all vehicle tyre pressures as they pass, and is immediately transmitted and uploaded to the dashboard display on the ContiConnect system, highlighting any tyres with under-inflation and increasing temperature problems.

“This is a massive advance on normal driver checks,” says Ian Jackson, Continental Tyres’ UK Technical System Sales and Service Manager. “It delivers accuracy far beyond a driver’s simple visual check and alerts operators to problems before they become dangerous. It’s a major safety and fleet performance bonus for any operator, and for yards where vehicles come and go on a daily or shift basis, it can be even more valuable. It can also be replicated in an operators’ other yards, with the information updated instantly back to the main office.”

The operator runs Continental Tyres across its fleet, using 385/55 R22.5 ContiHybrid on first, second and tag axles across a range of its trucks, as well as being an early pioneer of 315/70 R22.5 Conti Hybrid on drive axles. The 385/55 was an uncommon size for many years, though Andrew says: “The European trucks I saw coming in were using a lot of them and, when we looked at it, we could see immediate advantages in terms of their low profile helping loading heights on trailers. The additional big bonus is that, through the ContiRe retreading programme, our local dealer can take all the truck tyres and have them retreaded and available again for a very useful second life on trailers.”

Andrew concluded that the company has been impressed with the value the Conti YardReader Station and ContiConnect have brought to his business: “We have a great relationship with Continental, so were happy to trial what we were told would be another advance in tyre management – and so it has proved to be. The technology has demonstrated its value over and over again during the past year.

“Off-site, tyre-related breakdowns have reduced dramatically, and the fact we are now running perfectly balanced tyre pressures across each rig has to be contributing significantly to fuel savings and enhanced overall performance. Anyone in transport knows well- maintained tyre pressures mean better economy, performance, and safety, because we can now deal with potential problems before they cause real issues for a driver and other road users.”