In a CVW exclusive, Bridgestone’s Solutions Segment Leader, Panos Tsonis, provides an in- depth insight into the FleetPulse solution, including where the concept was originally born, how easy it is to use, and how it simplifies fleet operations and reduces downtime.

When Bridgestone’s three-in-one FleetPulse solution was unveiled to the commercial world towards the end of last year, businesses were promised reduced downtime, greater transparency of vehicle health and a reduction in potentially dangerous breakdowns. With the technology now on the market, a number of fleet partners are signing up to make the most of its many benefits.

The beginnings of FleetPulse

New social, economic and technological megatrends are pushing the pace of change in the automotive industry, with the future of vehicles connected, autonomous, shared and electric (CASE). With this in mind, Bridgestone has identified digital mobility solutions and fleet solutions as a priority.

This is reinforced by the growing importance of fleets over individually- owned vehicles for transportation of people and goods. Increasing demand in the transportation industry means that fleet owners and managers need to maximise productivity and minimise total cost of ownership more than ever.

This has resulted in the launch of a range of digital solutions and applications, such as FleetPulse, Tirematics, Mobox and Bridgestone Connect. FleetPulse is a three- in-one solution, comprising a mobile app, a centralised website, and Tyre Pressure Monitoring System (TPMS) hardware, keeping fleets one step ahead of their maintenance activities.

Staying connected

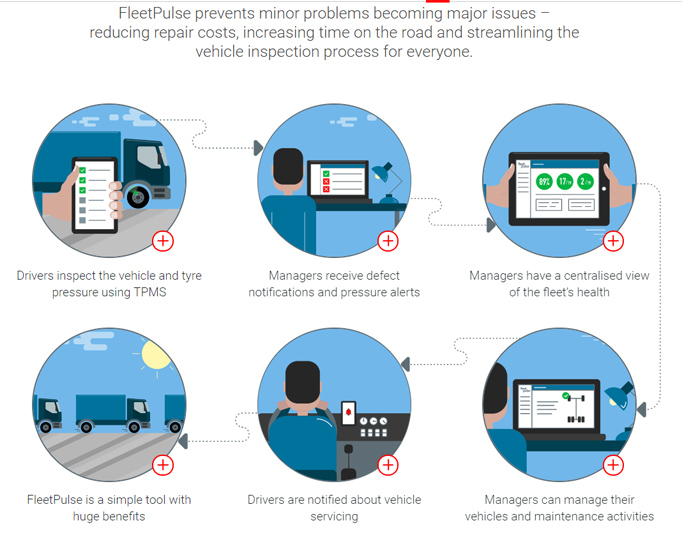

FleetPulse provides fleet customers with insights to help them understand what is happening with their vehicles. With the designated FleetPulse Android app, it is easy to complete their road-compliance checklists.

Through the centralised FleetPulse online portal, fleet and maintenance managers can have a real-time view of the whole fleet via the cloud, including defects and damage as well as performance data. They can then individually notify technicians through the FleetPulse App about new checklists, service bookings and even the removal of vehicles from the road.

In addition to this, when used with the TPMS, users will be able to automatically check a vehicle’s tyre pressures and receive alerts if they are too low. Correctly inflated tyres significantly reduce breakdowns to ensure that customer deadlines aren’t missed, and costs are reduced.

Top features

Vehicle checklists

Bridgestone’s vehicle checklist app for drivers is simple. It’s customisable, and allows them to log defects and share them with other users, along with comments and photos. It’s also tamperproof and audit- compliant.

Vehicle management

Managers receive email notifications, and an online dashboard allows them to manage their fleet in real time, and check the vehicle’s status and its history backlog.

Service bookings

Perhaps most importantly, managers can also book services or workshop appointments through the online dashboard. The details of what’s being carried out on a vehicle are then automatically sent to the relevant drivers.

TPMS

TPMS allows the fleet to easily keep tyre pressure at optimum levels, via the app, a dongle and the tyre sensors. It helps the fleet to reduce tyre costs, fuel consumption and the number of breakdowns.

The secret is TPMS

Technicians, drivers and fleet managers can also benefit from new insights into tyre health. The service comes with TPMS hardware for the vehicle, consisting of Tirematics sensors and a dongle. FleetPulse automatically connects to the vehicle’s TPMS and collects data on tyre pressure. It then relays the results back to drivers and managers through the FleetPulse app and online dashboard in real- time. This helps to ensure tyre pressure is optimised, which is essential given that 30% of breakdowns are caused by low tyre pressure and 90% of tyre-related breakdowns are caused by slow leakers. Despite this, 20% of commercial tyres on the road are significantly underinflated. By ensuring that appropriate tyre pressure is maintained, FleetPulse avoids breakdowns, excessive wear of the tyre and unnecessary fuel burn – cutting unwanted tyre costs and CO2 emissions.

The sensors easily fit on each tyre, they have three-year battery life, they work with all commercial tyres and they seamlessly fit into daily walkaround checks. Based on the assumption that a typical tractor and trailer combination running at optimal tyre pressure can save, on average, up to £950 per year in fuel, tyre and breakdown costs, Bridgestone claims that FleetPulse would pay back its initial cost within a year.

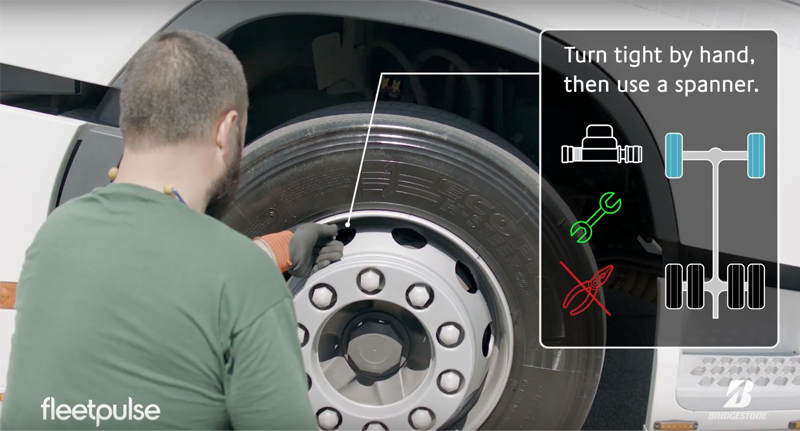

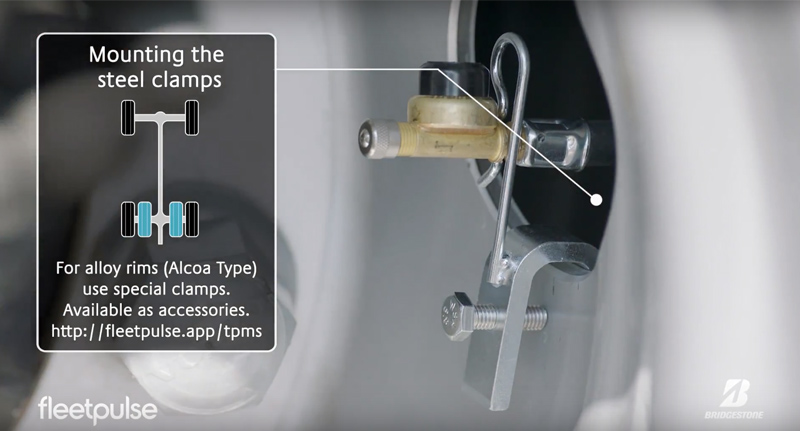

The fleet can easily fit the sensors without demounting the tyres, as they are connected in the existing pressure valves externally. In the pictures above, it’s shown how the three types of sensors can fit in the truck or bus wheels. The short sensors are fitted in the steer and trailer wheels, the short flexi in the outer drive wheels and the long flexi in the inner drive wheels.

How it works

Bridgestone claims that FleetPulse is the only solution on the market that combines vehicle checks, booking services, fleet management and TPMS in a single platform, as well as enabling real- time communication between drivers, technicians and fleet managers via the cloud. According to the company, FleetPulse can be used across all vehicle and tyre brands, and is available on Android devices.