Adam Pearce, Fuel Product Manager at Parker Hannifin, discusses how development in diesel engine design has led to an increase in susceptibility to fuel contamination.

Over the past two decades, diesel engines for commercial vehicles have seen a significant increase in performance and power, whilst managing to reduce their emissions output. Conversely, engine susceptibility to fuel contamination has increased, which is seeing increasing numbers of manufacturers turning to in-line fuel filters.

Some estimates suggest that up to 80% of diesel engine injection system failures result from contaminated fuel. Overcoming this problem is becoming a major objective for both engine manufacturers and fuel suppliers. As a consequence, commercial vehicle manufacturers can appreciate the financial advantages of installing pre-filtration systems within their engines to stop the harm that contamination can cause.

Fuel contamination can be catastrophic when it comes to the latest diesel fuel injection systems, especially with their exceptionally high operating pressures. Moisture or particulates are the prevailing forms of contamination, and while these can occur separately, they are often found together.

Condensation on the walls of storage or vehicle tanks that trickles into the fuel is the most common pathway inside engines when it comes to moisture. Along with the corrosion of injector nozzles and pumps, moisture offers the perfect breeding ground for micro-organisms. Furthermore, any fuel that contains water will inevitably compromise its properties as a lubricant.

Particulate contamination differs from the ingress of moisture in that it occurs at various junctures in the supply chain. Common culprits include dirt from transport, storage, a vehicle’s own tank, or particulates contributed to by water-borne micro-organisms and corrosion. Regardless of the source, the upshot for a modern diesel engine is little short of disaster. In many instances, it only takes particles measuring 5-10μm to lodge between injector valve faces and prevent full closure. The knock-on effects include leaks, lower combustion efficiency and potential failure of the injector itself.

Pressures as high as 30,000psi (2,068 bar) are prevalent in today’s advanced fuel injection systems, which make the potential impact of water and particulate contamination even more acute. To make matters worse, by the time that any deterioration in engine performance is detectable, it’s too late; the damage has already occurred.

Faced with such a situation, the only remaining option is the costly replacement of injectors and high-pressure pumps, but this can all be avoided with a simple and inexpensive filtration strategy.

Sure enough, almost every engine manufacturer installs a final particulate filter, but this is often of insufficient quality. In fact, the quality of such filters is often no better than those found at the refinery or filling station. Aware of this situation, a number of vehicle OEMs are seeking greater quality when it comes to filtration and water separation, increasingly through the fitment of in-line fuel filters.

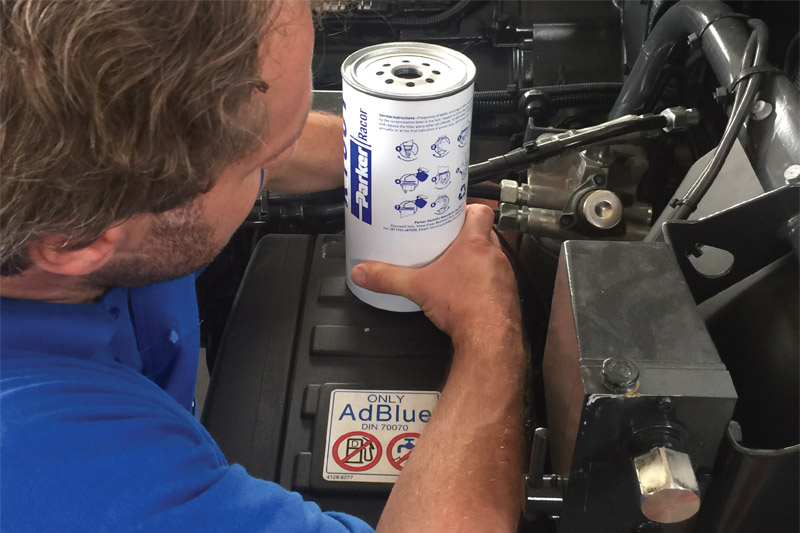

The Racor division of Parker Hannifin is a major manufacturer of fuel filters. Solutions offered by the company combine the functions of a particle filter and water separator in a single unit, providing filtration grades as low as 2μm. In addition, the filter head on selected models now includes a positive temperature coefficient (PTC) heater. A PTC heater serves to warm the fuel as it makes its way through the filter, lowering the potential of blockages resulting from a waxing-up of the fuel in low ambient temperatures.

Unlike many conventional fuel heaters found on diesel engines, Parker’s head heater offers self-regulating capabilities, so the power it draws depends on temperature and flow. Operating on 12 to 42VDC, a safe power down of the heater will take place when fuel flow through the line is absent, which ultimately helps to increase vehicle service life.

For those thinking that there will be high cost implications of introducing a fuel line filter to a vehicle that already houses an on-engine filter, think again. Just imagine the cost of replacing a new injection system damaged by contaminated fuel. In contrast, a fuel line filter typically costs just 25% of filling up with a tank of fuel.

For commercial vehicle and diesel engine manufacturers who want to help their customers achieve a considerable saving in long-term operating costs, there is a clear option available. Of course, for the independent aftermarket, any filter installed and specified by the OEM must be replaced in line with manufacturer service life recommendations. In addition, replacement operations should only be performed using parts that meet the required manufacturer standards. The fitting of some non-original components can lead to compromises in productivity and engine life, as well as higher costs and diminished profit margins.