Get over common misconceptions about tightening, and follow Chicago Pneumatic’s recommendations to ensure you are providing the right level of torque.

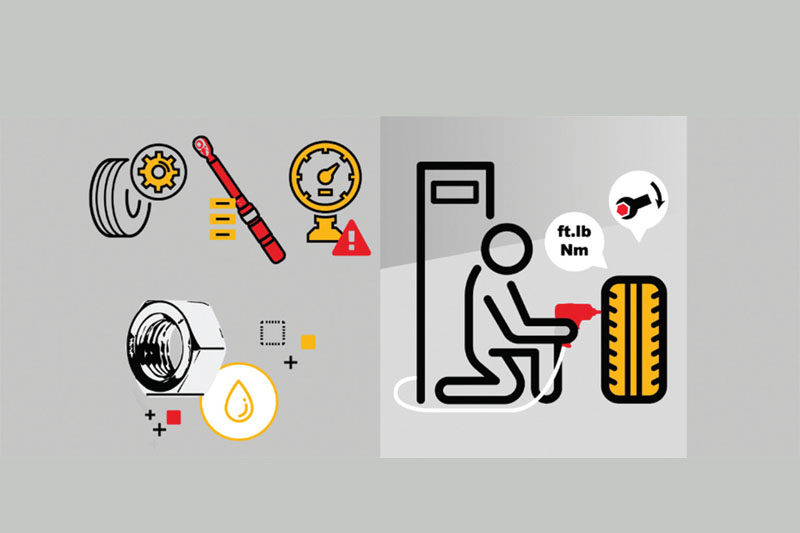

As maintenance professionals, you need to ensure that the heavy vehicles that pass through your workshop are appropriately maintained, following manufacturers specifications, especially when it comes to tightening applications. One specific area that needs attention is wheel changing.

Fact or fiction?

Wheel changing needs to be achieved quickly and simply to maximise profitability, but there is also a major safety element that needs to be part of the equation – the correct application of torque.

Over-tightened and under-tightened lug nuts can result in potentially catastrophic failure of the wheel. Over-tightening wheel nuts risk becoming damaged, stretched and broken, especially when hitting potholes and bumps in the road, whilst wheel nuts that are under-tightened can back out or sheer off, causing premature wear and separation of the wheel from the hub.

Irregular nut tightening on the same wheel is also a problem; it can lead to the movement and vibration of broken nuts, as well as wheel detachment. Tyre changing on any type of vehicle is a regular job for technicians, and it can seem quite straight forward. As such, operators often overlook the tightening specifications recommended by the vehicle manufacturers. This should be avoided at all costs, as it can lead to downtime and serious safety consequences.

Common misconceptions ‘heard in the field’

- ‘The more you tighten, the better’ is a phrase often said regarding wheel nuts, and it is false. In most cases, more torque means more tension applied to a bolt, resulting in over-tightening, which increases the risk of stud break

- ‘The more a truck is carrying, the more you need to tighten’ is also a myth; manufacturers recommended that torque specifications should always be followed. Believing this myth can lead to over-tightening and its disastrous consequences

- Another misconception is that ‘to get the right torque applied, you just need to count 1, 2, 3 while tightening’. Proper torque requires the use of the correct tools, procedures and patterns.

Stick to specifications

Manufacturers always provide recommendations for each tightening job, and these can be found in the specifications book or maintenance manual, which is more commonly called the ‘blue book’. Before you start tightening, you should double check the book to ensure your job is performed to the best standard.

With new innovations in materials and tools, it’s important to keep your knowledge current and follow the latest specifications. For example, nowadays most wheel rims are made from aluminium instead of steel, but this does not mean that aluminium rims are harder, and more torque is needed. The rim material affects the torque that should be applied. Continuous training is highly recommended, and this can be offered by different providers.

Surface preparation is also key, as a substantial amount of torque is ‘lost’ or wasted by friction during tightening. Therefore, Chicago Pneumatic advises preparing the surface properly by cleaning all the elements to eliminate any rust, dust and dirt. Once you finish cleaning and before you start tightening, inspect all components: wheel, studs and long nuts.

The company also recommends using the appropriate tools for commercial vehicles to prevent over-tightening, such as the CP7782TL-6, which tightens bolts according to vehicle manufacturers’ recommendations and increases the operator’s efficiency. It’s ideal for tough and hard-to-remove, over-tightened bolts, delivering high power in reverse up to 2,600Nm. Also useful is the CP8925 Torque Wrench 1” square drive, with 200-1,000Nm and an accuracy of 4% according to EN ISO 6789:2003 specifications.