A deep dive into wet timing belts

Lou McCaskill, GT Automotive Parts, looks at wet timing belts, their purpose and the issues they’ve created in the popular Ford Transit amongst other vehicles.

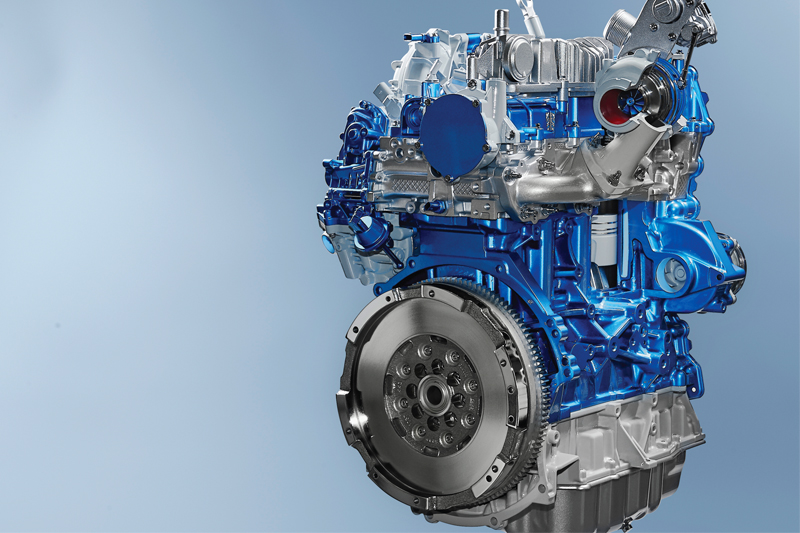

In 2016, Ford introduced the Ecoblue engine, which is featured in most Ford vehicles including the Transit. Its inclusion didn’t come without issues. The introduction of the wet timing belt was one of the predominant differences in the Ecoblue when compared to its predecessors. It’s no secret that wet belts incurred the wrath of many and generally displeased the rest. Originally designed to reduce carbon emissions and increase performance, the belt in oil system very quickly made its way to becoming one of the most problematic parts. With frequent premature failures and a difficult and expensive replacement process, the wet belt became a good reason to stay clear of this engine.

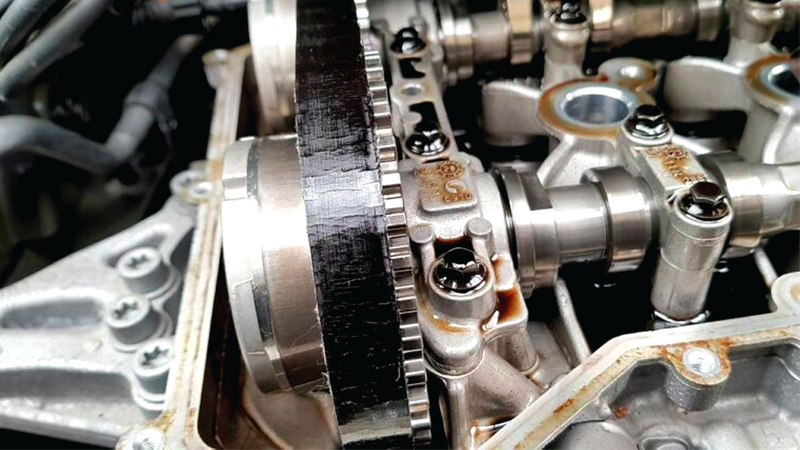

We all know the role of a timing belt – to ensure the camshafts and crankshaft pulleys are kept in sync, so that the engine valves close in time with the pistons to make sure they don’t collide, causing catastrophic damage to the engine. And we all know that normally a timing belt is usually installed on the outside of the engine, protected by a cover. And it does its job.

So why install a timing belt inside the engine and submerge it in oil? Well, the original intentions of the wet belt were:

- to increase the period between maintenance; lubrication from the oil means that it would reduce wear and friction, extending the life of the belt and reducing fuel consumption and CO2 emissions

- to help reduce engine temperatures; any heat generated by the timing belt would dissipate into the oil

- to reduce noise; any noise or vibration from the timing belt would be dampened by the oil

The first ‘belt-in-oil’ system was installed inside of European-market 1.8 Ford diesels, the 1.8 TDCi engine. Volkswagen then followed, installing them into some of its EA211 and EA288 families of engines. In 2010, Ford released its Ecoboost featuring a wet belt and the Ecoblue came out a few years later in 2016, which can be seen in a wide range of applications.

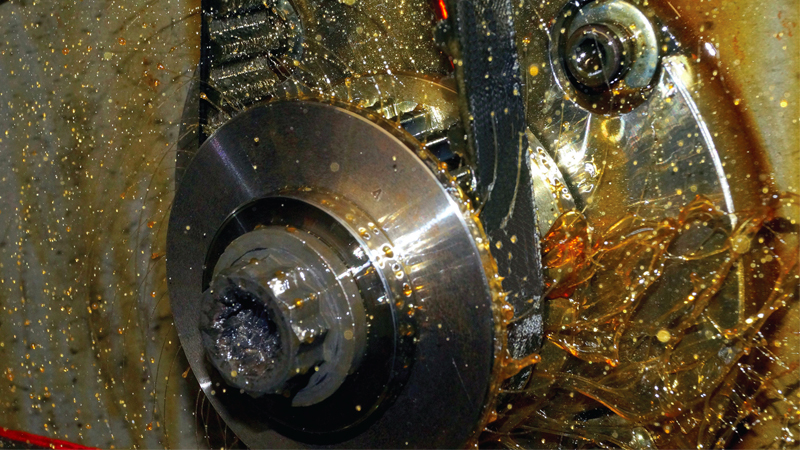

One of the biggest factors that cause timing belts to fail is contamination of fluid, including oil. This is why many of us are so surprised to learn about the existence of the ‘belt-in-oil’ system. Once oil starts to get onto the timing belt it infects the rubber and weakens it until the teeth come away or it snaps, so putting these two components together in the same system seems like a recipe for disaster.

Issues

Originally, the wet belt aimed to solve a simple issue. Vehicle manufacturers needed to decrease overall emissions and installing a wet belt was one of the cheapest and easiest ways to do this. The wet belt offered a 30% reduction to friction loss and would reduce emissions, increasing fuel economy by just over 1%. This compact and quiet belt drive was being heralded as the way forward for the automotive industry.

Anyone who has dealt with a wet belt will know that the problems it aims to solve do not outweigh the issues that it causes.

The main issue is that any minor impurities in the oil, such as soot or crystalline, can lead to premature belt wear. This will cause material from the belt to come loose inside the oil and clog the oil sump filter, producing oil starvation. Additionally, the brake vacuum pump can also be affected increasing the risk of an accident due to ineffective braking.

On top of this, the extra work required to change a wet belt is a lot more onerous than changing a dry belt. In order to access the belt, the chamber needs to be drained of oil and most of the engine needs to be disassembled to access it. This means that replacing the belt, or even doing routine maintenance, takes a lot more time and work than that of a dry belt.

Dayco, one of the leading manufacturers in wet belts, has exaggerated the point of regular and proper maintenance in order for drivers to get the most out of their timing belts. Insufficient oil levels, neglecting to carry out proper maintenance or using improper oil could have an adverse effect on the belt.

It is important to note however that most drivers are reporting their timing belts failing prematurely. While Ford is advising that the belt is replaced every 144,000 miles or every 10 years, a lot of garages are insisting that drivers have them replaced at around 90,000 miles or every five years.

There are no clear signs that a wet belt may be failing. When carrying out maintenance on a dry belt it would need to be visually inspected, as it usually won’t give any audible warning that it will break. Considering that any noise generated by the wet belt is dampened by oil, drivers will need to be reliant on other factors to tell if their belt is failing.

When the timing belt is worn the engine may have difficulty starting and can run poorly while idling and operate erratically at high speeds. Wet belts are less likely to break, however their teeth can come loose, and this would lead to belt skipping and the engine becoming desynced. If the belt is weakened it may still operate but will continue to contaminate the oil with debris.