Air conditioning condenser advice

Effective air conditioning is a very important factor for the wellbeing of the drivers responsible for delivering goods throughout the country, and for the vehicles carrying the loads, which is why the regular maintenance of the A/C system should be a priority for every fleet operator, argues Nissens.

Although every part of the A/C system is vital to ensure that it all operates effectively, without the correct amount of refrigerant it will not be able to deliver the cooling efficiency it’s designed to and it could also have a catastrophic effect on components, such as the compressor. However, with regular A/C maintenance, the refrigerant can be kept at the correct level, which will allow the system to run efficiently at full capacity. In addition, regular checks at least once a year, can also help identify potential faults and prevent other problems arising, significantly lowering overall running costs.

As the refringent in the sealed loop within the system is pressurised, and that pressure increases as the A/C is being used, the risk of leaks is an ever-present threat. Therefore, examining the overall tightness of the system, including the integrity of joints and seals, is an important aspect of maintenance and should be undertaken every time a vehicle enters the workshop.

However, the most vulnerable component within the A/C system is the condenser, because its intricate design makes it relatively fragile and its positioning, which needs to be in an unrestricted airflow, means that it is also susceptible to damage from salt spray and debris thrown up from the road, as well as from bird strikes or impacts from other foreign objects.

Condenser replacement guidance

Should the condenser require attention, it is crucial to inspect it thoroughly, including a detailed surface and joint inspection to spot possible leaks. Stains that attract dust highlight potential leak spots, as the leaking refrigerant leaves lubricant tracks that it sticks to. If necessary, repair all the components related to its seating and mounting because issues like rust and cross threaded screws will complicate the installation process.

Removing any rusty parts and applying an anti-corrosion coating to the repaired components is a good way to ensure their better ongoing protection. Also, to avoid unnecessary vibrations affecting the new condenser, it’s recommended that rubber pads and inserts are replaced as well. Additionally, ensure that no tubes or electrical wires are rubbing against the new condenser, as this could cause unnecessary damage and shorten its lifespan or lead to other serious problems.

Before installation, all gaskets must be replaced, and the O-rings lubricated with oil designed for the A/C system in the vehicle and if the drier is not an integral part of the condenser, it should be replaced before installing the condenser.

When installing the new condenser, inspect for cleanliness and tightness, and if necessary, repair parts and the related connection couplings. It’s also important to remember that it should not be adapted to fit the mounting area by being bent, stretched, or forced into place, instead it should locate easily on its mountings.

Effective leak detection

After installing the condenser, it is essential to check the entire system for leaks, ideally with one of the following procedures: UV dye tracking, prolonged pressure test with nitrogen charge and electronic leak detection, and/or a longterm vacuum test, as examples.

However, to ensure the optimal tightness of the system, Nissens Automotive, recommends the long-term nitrogen/nitrogen compound test method, which should be undertaken for as long as possible, but for two hours at an absolute minimum, ideally at above 10bar/145 psi pressure. Do not exceed the systems maximum operating pressure, typically 32 bar. Providing that there is no pressure loss on the control pressure gauge during the extended test period, the system can be filled with refrigerant.

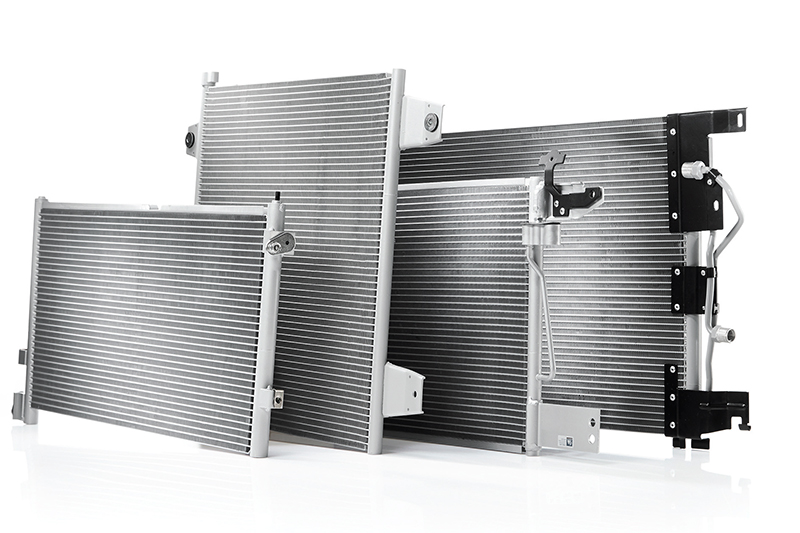

Condenser design

The condenser is an aluminium alloy component that plays a critical role in facilitating the refrigerant’s thermodynamic transitions between gas and liquid, a process that is essential for cooling the vehicle’s cabin. The component is in the front of the vehicle, so is exposed to the elements, and features numerous thin fins, which are specially designed metal slats that facilitate heat transfer.

Unfortunately, these fins can be easily damaged, leading to a significant decline in the A/C system’s performance. In extreme cases, the damage can lead to micro leaks in the condenser tubes, allowing the refrigerant to escape. As a result, the condenser is one of the components that most frequently requires replacement, which is why choosing one of the appropriate quality is vital.

To that end, Nissens Automotive has developed a special corrosion-protective coating that aims to considerably extend the lifespan of its condensers. It is based on a powder coating that precisely covers the entire surface of the part, creating an effective protective barrier thats helps to repel corrosive agents attacking the surface.