AP Air offers its guidance on how to understand the working pressures of R134a systems.

The pressure readings on your air conditioning service station can tell you a great deal about how the system is performing and detect any major issues within it. The AC system is divided into two halves: the low pressure side and the high pressure side. Understanding the relationship between the two pressures will help you understand what is happening within the AC system.

The issue

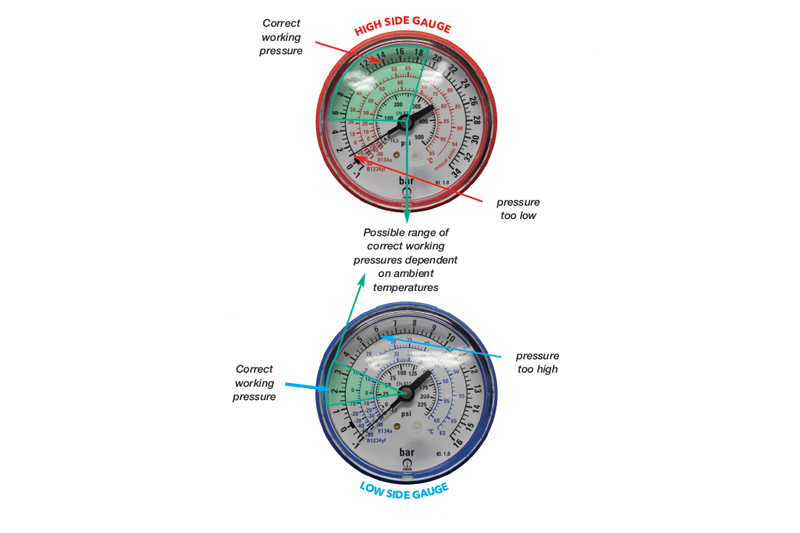

Normal operating pressures on the high and low sides should remain within a certain range (see gauges opposite) to ensure the best performance of the AC system. If either of the readings are outside of the shaded ranges it could mean that there are operating issues within the AC system that need to be looked into and resolved.

The test

Before undertaking a pressure test of the system, you must make sure that the system is in working condition. First, you need to ensure that the system has the correct amount of refrigerant and at least 1.5-2 bar (25-30 PSI pressure) in the system to enable the compressor to run.

The static pressures should be read before the car is started. Both gauges should be close to equal pressure readings. If the pressure readings are too low, this indicates there is not enough refrigerant in the system – investigations into a possible leak should be made.

If the static pressures are as they should be, you can now check the working pressures of the system. To do this, in an ideal circumstance, you need to let the vehicle idle so that the engine reaches normal running temperature. Once the engine has reached its normal temperature, turn the AC on and set it to recycle and on full.

Next, look at the gauges and watch the pressures as the compressor comes in and out. If the readings stay static, you know that the compressor is not pumping, which could be a compressor fault or an electrical fault in the system and would then need to find the fault. Remember that your pressure readings will be affected by the ambient temperature; for example, on a hot day your readings may read higher than they would on a cold day.

Issues that could cause the high side or low side to operate outside of the normal perimeters. Too much or too little refrigerant will affect the working pressures of both sides of the system. Too much oil or dye in the system will affect the working pressures, as will some additives such as an AC booster, and leak-stop may affect the working pressures too. Blockages or any kind of flow restriction within the AC circuit, such as debris from the compressor or broken down receiver drier, moisture, and contaminated refrigerant, will all have an effect on the high and low pressure readings.

A blocked condenser or blocked TXV valve would also have a detrimental effect on the pressure readings of the system. Leak-stop being incorrectly used in the system could cause a blockage. Insufficient air-flow through the condenser would impact the readings.

For example, this could take the form of the condenser fan not working, fins missing from the condenser, or the condenser being clogged with leaves and debris reducing the air flow and the cooling capacity of the condenser and affect the pressure readings. A failing compressor would also see the pressure readings staying static as there would be no compression of refrigerant to create high pressure and no suction on the low side gauge.