BPW runs through its guide to the correct lubrication of automatic slack adjusters and camshaft bearings.

BPW recommends that automatic slack adjusters and camshaft bearings are greased at least every six to eight weeks, not exceeding 12 weeks for UK operations.

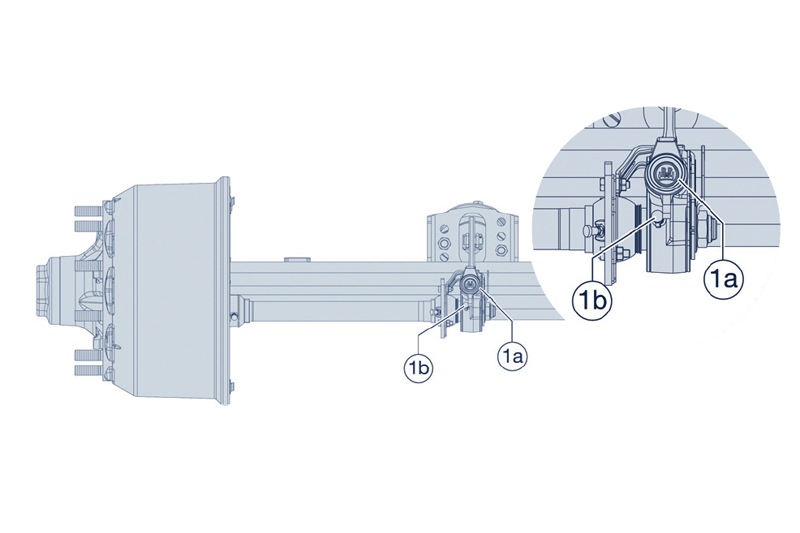

Points of lubrication – slack adjuster

Lubricating the slack adjuster requires removing the slack adjuster dust cap (1a) and applying the grease via the grease nipple (1b) until the old grease is purged out and the new grease emits from the adjustment bolt housing. Make sure to refit both caps.

Less than adequate lubrication, and the absence of the slack adjuster dust cover, allows ingress of dirt and moisture which will compromise the performance of the slack adjuster.

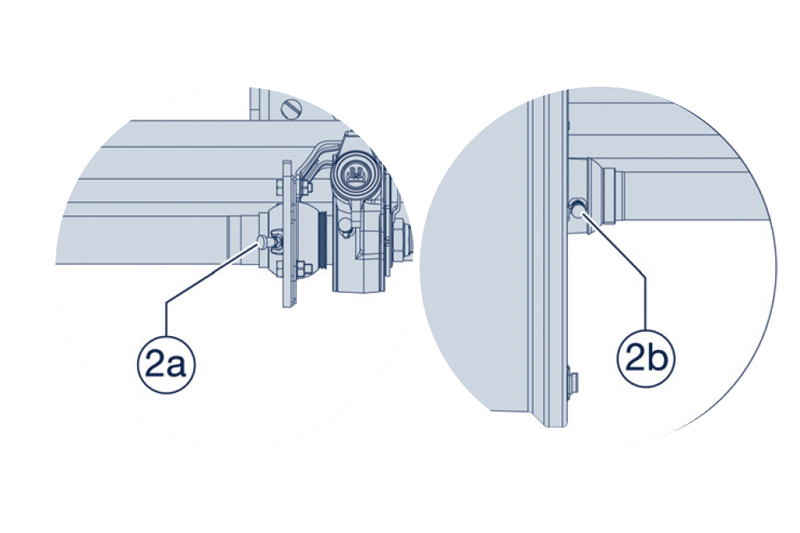

Points of lubrication – camshaft

Lubricating the inner spherical bearing (2a) and the outer camshaft bearing (2b) requires removing the plastic grease nipple cap and connecting the grease applicator to the nipple.

- Fresh grease should be delivered until visible at the seal

- Remember to refit the plastic grease nipple cap

- If, after three or pumps, no grease appears from the seal (old or fresh grease), stop and inspect the opposite end of the outer camshaft bearing – there should be no grease in the area highlighted. If grease is visible, it is advisable to check the condition of the bush and seal arrangement.

- If no grease enters the bearing area, check the grease nipple for blockage and replace if necessary. If the grease nipple is clear, check the bush for blockage.

- Failure to follow these recommendations could result in premature wear to these components shown

Maximum bearing play must not exceed 0.8mm for the inner and outer cam buses (manual lift only, no assistance from bars).