BPW runs through its technical guide to the automatic slack adjuster and the issues to be aware of when undertaking maintenance and repair.

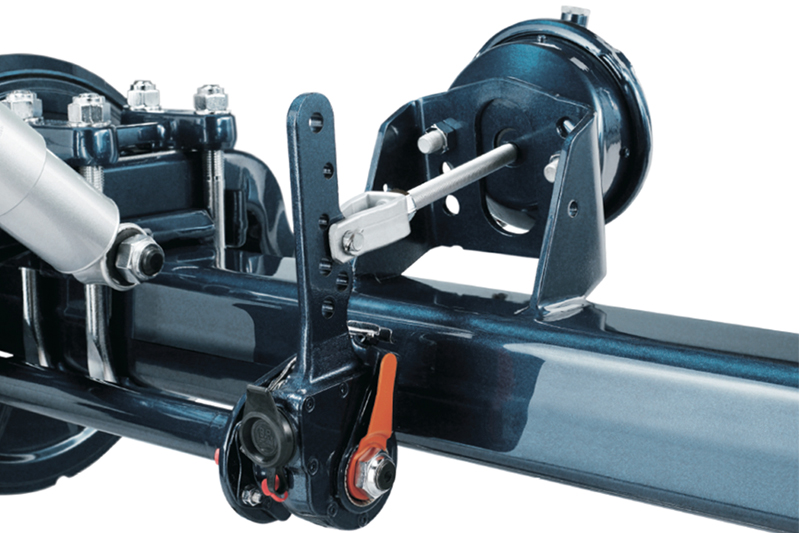

The BPW drum brake is a simplex (single camshaft) ‘S’ cam operated unit that comes in three sizes – 420mm, 360mm, and 300mm diameters. The camshaft is supported in two bearings:

Outer camshaft bearing

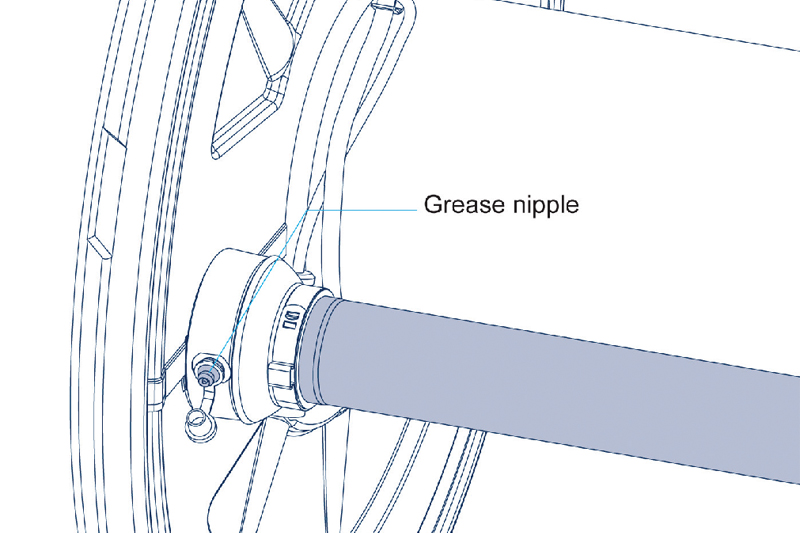

The outer bearing (bush) is of rolled nonferrous construction and has greaseways rolled into it. The grease is contained in reservoir holes punched through the bush. The grease is applied through a grease nipple positioned just behind the brake back plate (Fig. 1).

BPW ECO Li Plus grease should be applied until fresh grease emits through the dust cover, with the period of greasing being every six to eight weeks. There is an ‘0’ ring positioned near to the outer edge of the bush to prevent grease from escaping into the drum and contaminating the friction surfaces.

Inner camshaft bearing

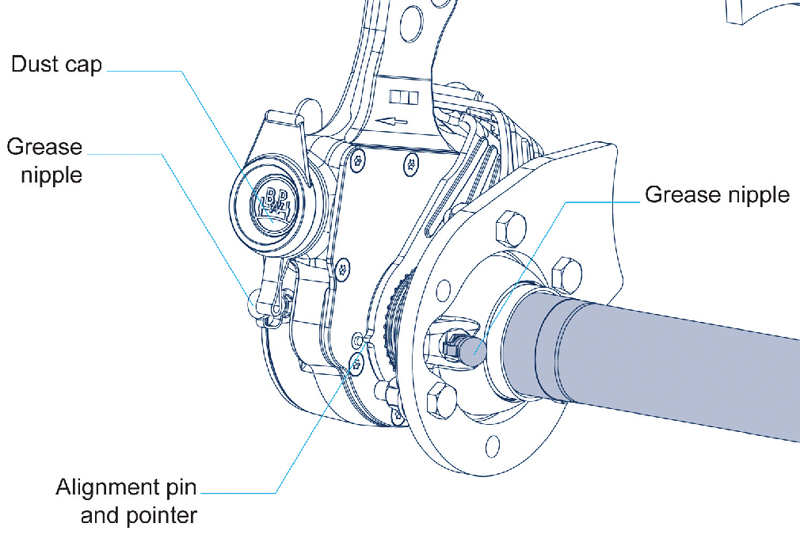

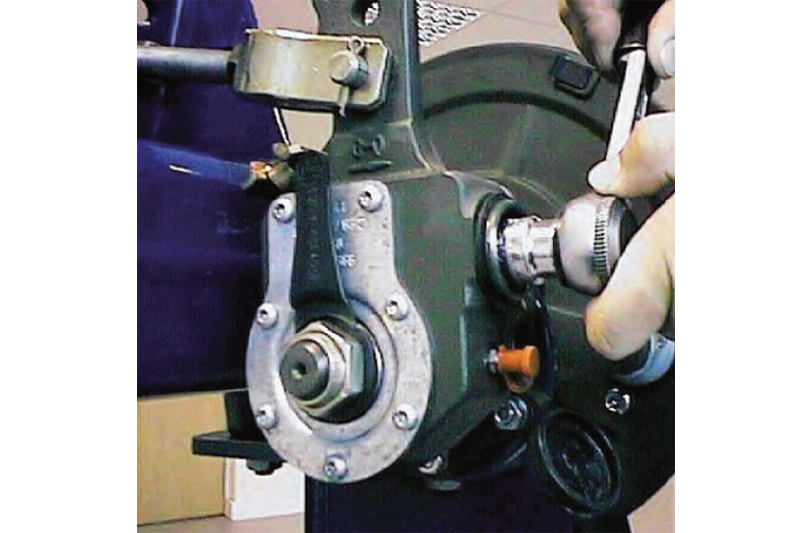

The inner bearing is made of sintered steel and is a self-aligning spherical design. The bush has greaseways and reservoirs formed into it during the sintering process. The bearing is held in place by half-shells bolted to the inner camshaft bearing bracket. A grease nipple is provided and the level and period of lubrication is the same as for the outer bush (Fig. 2).

The camshaft is connected to the air chamber by an automatically adjusting slack adjuster. The slack adjuster is located on the splined end of the camshaft and is secured by a nut. Again, a grease nipple is provided for lubrication and this follows the pattern previously mentioned.

The key to long life and efficient operation of this system is correct lubrication and adjustment. Correct inservice adjustment of the brake should be checked periodically: with the brake released, the pin and pointer on the side of the slack adjuster should be exactly in alignment (Fig. 2a).

Note: If this is not the case, then it will not be possible for the slack adjuster to auto-adjust properly and BPW should be contacted for advice before proceeding further.

Adjusting the free play

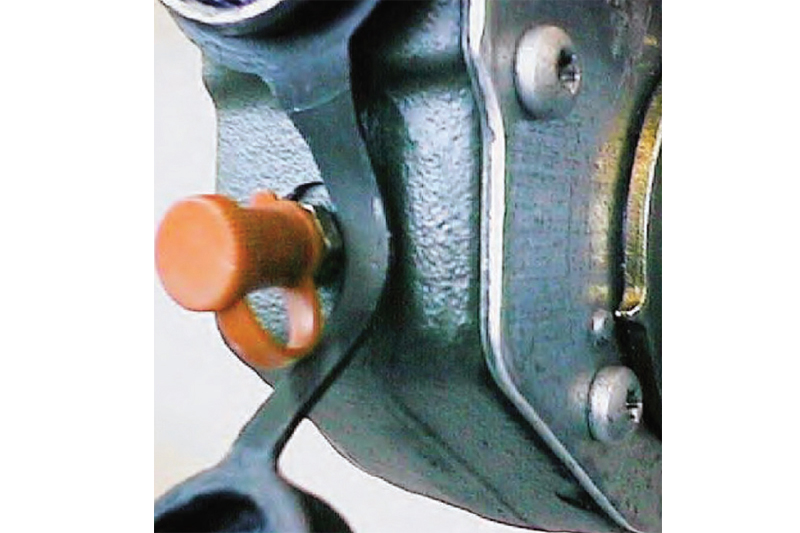

Assuming that the pin and pointer are correctly set, then the most convenient way to adjust the free play is to use a 19mm socket to wind on the brake until it just binds and then release the brake by turning the adjusting bolt one half turn anti-clockwise (Fig. 3). The adjusting bolt is located under the plastic dust cap on the outer face of the slack adjuster body.

Note: To back off the brake, the adjusting bolt has to be rotated anticlockwise and to do this the socket has to be pressed into the slack adjuster quite hard against a spring to release the clutch. If you try to force anti-clockwise rotation without depressing the internal clutch then the mechanism will be damaged.

Twice a year, the slack adjuster should be checked to ensure that the automatic adjustment is working correctly. To do this, remove the plastic dust cap and wind off the brake by turning the adjusting bolt approximately one and a half turns anticlockwise. Then, either by hand, or by having an assistant operate the footbrake, apply and release the brake half a dozen times.

You should be able to hear a definite click as the slack adjuster over-strokes and when the slack adjuster is on the return stroke you should see the adjusting bolt wind on clockwise. It is a good idea to purge fresh ECO Li Plus grease through the slack adjuster whilst carrying out this procedure as this ensures that the grease finds its way around the internal clutch mechanism.

Always remember to replace the dust cap after any adjustment and if the cap is damaged new ones can be obtained. If dust and dirt are allowed to get into the adjuster port this will lead to premature failure of the unit. Remember to adjust the brake before the vehicle goes back into service.

Lubrication point

An often neglected lubrication point is the clevis pin which connects the slack adjuster to the brake cylinder pushrod. This should be kept greased to prevent seizure which will degrade brake performance.

After a number of years, wear will take place predominantly in the outer camshaft bush and on the camshaft. This wear can be tested by placing a pinch bar under the camshaft behind the brake backplate and on the top of the suspension clamping plate. If excessive lift is shown then the camshaft and bushes must be replaced.

Camshaft bushes are obtained as a BPW kit that contains enough parts to refurbish the complete axle Camshafts are obtainable singly and are handed. It is advisable to replace both camshafts across an axle and bushes at the same time.

Location of the pull-off spring

When carrying out a brake re-line make sure to remove the brake rollers and lubricate the brake roller bushes with BPW’s ECO Li Plus grease.

Do not put any grease on the head of the camshaft. When re-lining brakes always fit a new brake shoe pull off spring.

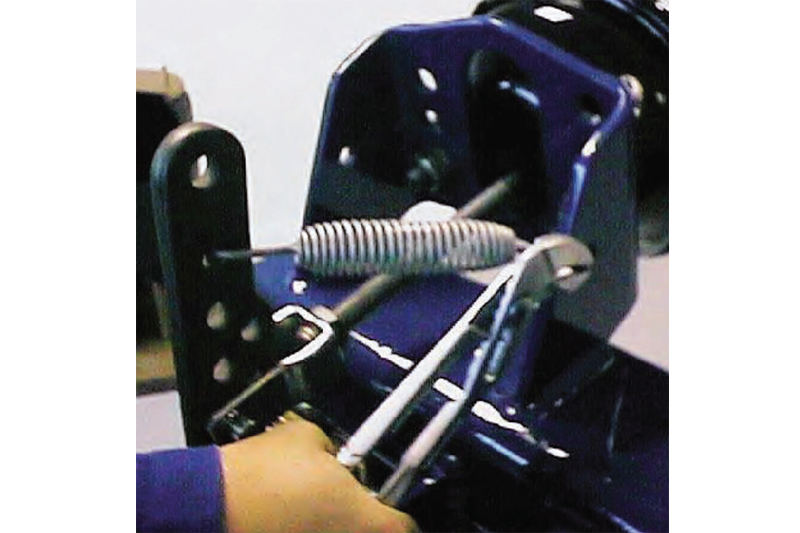

Finally, in the UK, BPW fits a pull off spring between the slack adjuster and the air chamber bracket. (Fig. 4)

These springs should be renewed at every brake reline and always use the special hole provided in both the slack adjuster arm and in the brake chamber bracket.

BPW Automatic Ecomaster Slack Adjuster

BPW Automatic Slack Adjuster replacement requires some knowledge and understanding when replacing. In-service testing and functionality checks are mandatory to ensure compliance and correct operation.

- Brake chamber push-rod length movement when brake is applied from static should be checked dimensionally against brake calculation lever length – typically 15-22mm movement 10 – 15% of effective lever length.

- Manual intervention should not be required, if the adjuster is functioning correctly the free play should conform to the above dimensional requirements.

- A functionality check should be carried out if not:

- Having fully depressed the adjuster collar using a good quality 19mm socket, de adjust the brake with the hub spinning free approximately 3⁄4 of a turn or at least 50mm free play.

- Operate by hand several times and on return, adjustment should take place, the adjuster bolt turning in a clockwise direction and the adjuster collar ratchet should be audible.

- If the free play is not taken up and combined with no audible adjustment replace the BPW slack adjuster with BPW OE product.

- The adjuster must be replaced in accordance with the BPW maintenance instruction.

- The set-up procedure must be followed paying particular attention to the adjuster pin and pointer as well as the wear indicator positioning, final tightening sequence of the securing nut and spherical bearing, lubrication using BPW Eco Li Plus grease and reattaching the sealing rubber cover and final brake adjustment at 1⁄2 turn release from brake bind.

- Good practice would be to undertake a laden dynamic brake roller test to confirm compliance with the required minimum brake forces and imbalance allowances across all axles of the trailer.

Consequences:

- If manual intervention is required (initial set-up, brake reline or hub maintenance) failure to depress the adjuster collar fully will damage the internal adjuster lever and it is likely will render the unit inoperative – enforcement issue.

- As a further significant consequence, if damage remains undetected at the adjuster lever (automatic functionality inoperative) under certain conditions, the brake could back-off and excessive brake shoe to drum clearance could result – enforcement issue.

- Failure to adhere to the set-up process in full could result in poor efficiency or an inoperative brake – enforcement issue.

- Failure to adequately lubricate with the approved grease and refit the adjuster rubber cap or ensure it is in-place will allow water and dirt ingress affecting the efficiency of the adjuster and brake performance – enforcement issue.

All of the above will impact on operator OCRS scoring.