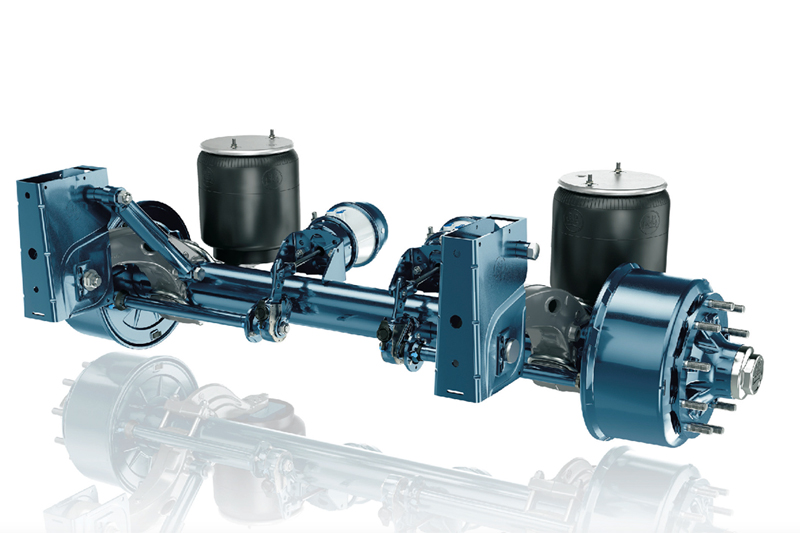

Keeping vehicles on the road and not unnecessarily in the workshop is key to a successful operation. BPW explains how investing heavily in its braking systems results in high performance, low maintenance equipment designed to keep downtime to an absolute minimum and customer’s vehicles on the road for longer.

When choosing your braking system, trailer/tractor compatibility, together with a vehicle’s working environment, are vital factors to performance and should be considered when choosing the brake for your operation. Here are some pointers to help you make the right decision. But remember, if you’re debating whether to go drum or disc, there is no clear, black and white answer. Everyone has their opinion. We’ve highlighted some key points, so you are better informed when making that decision.

Cost

Cost is a major factor when buying, and in most cases it is one of the first considerations in deciding to fit drum or disc brakes. As well as the purchase price, you should consider the cost of replacement parts, maintenance costs and labour time, i.e. long term cost effectiveness.

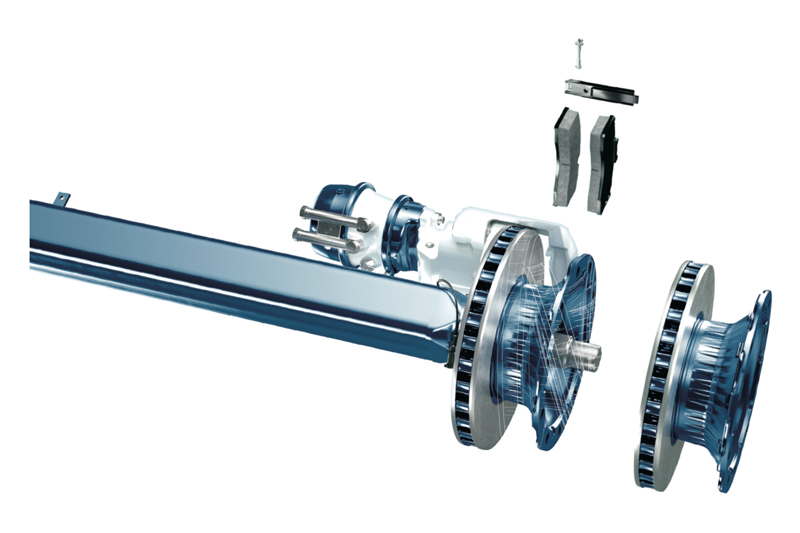

Whilst a disc brake has fewer replaceable components when compared with the drum brake, the cost when first purchasing the disc brake set-up is on average, higher. The long-term advantage is that with modular components, there is less to replace, therefore servicing time is reduced. The cost of replacing modular parts for a disc brake is much higher when compared with a drum equivalent, with the calliper and disc accounting for the large majority of the cost.

When comparing the BPW standard times for replacing equivalent components, the difference is negligible and, of course, the standard times are just a guide. Experience would be the deciding factor when comparing the labour time to change components.

As a result of disc brake components being higher in cost, the drum brake residual value is deemed higher, particularly when fitted with BPW axles. At the end of the desired life of the trailer the owner may want to sell it on, and with the market more favoured towards drum brakes it will be easier to sell. Another purchasing consideration when buying second hand trailers is the cost to renew components that have had a long service life and as mentioned previously, drum brake components cost less to replace.

Operational decisions

Choosing the right brake is dependent on the day-to-day operation of the trailer. The disc brake has a better braking efficiency at higher temperatures and is less likely to be subjected to brake-fade issues. This is because as the disc increases in temperature it expands towards the pads. When the drum becomes excessively hot it expands away from the shoes, and on rare occasions can expand to the point where no matter how far you press the brake pedal, the shoe will not make good enough contact with the drum to stop the vehicle in good time. However, with the fitment of retarders/exhaust brakes, this issue is very rare in the UK.

The disc brake set-up is fairly exposed to the elements and dirt, grime and water ingress from the road surface will have a bearing on braking efficiency and the maintenance intervals required. If a disc brake is used on muddy roads or tracks, the vent holes on the disc rotor can become blocked, causing the disc to become hotter much quicker and for longer periods of time. Drum brakes, on the other hand, are better protected from outside elements, blocking the majority of moisture and dirt, which is why they are a preferable choice when it comes to certain applications such as forestry and site work.

If a trailer is part of a rental fleet and under-utilised, it’s not uncommon for the brake disc to become rusty. This is because a trailer can be stored for long periods waiting to be leased, therefore out-of-use maintenance is required to ensure the integrity of the disc and pads are not compromised, whereas for drums this is not an issue. Also, when leasing trailers, the towing vehicle make and model will vary, and discs are more sensitive than drums when it comes to the issue of trailer / tractor combinations.

Most modern tractor units have Coupling Force Control (CFC) integrated into the EBS system. This is designed to give the optimum braking performance and compatibility between tractor and trailer. From our experience, and research, the CFC tends to be more sensitive and in some cases the trailer was found to take on more of the braking load than the tractor unit. This can result in the brakes running hotter and the discs and pads wearing more quickly. The drum brakes’ operating temperatures are also considerably lower, and this results in less thermal loading upon adjacent components such as tyres, camshafts, hubs, and hub bearings.

Maintenance comparison

Brake shoes are often sent for re-line at the end of their lining life which can bring down the cost of replacing the friction material in brakes. A disadvantage when sending the shoes away is that you may not get your shoes back. It is advisable to mark your own shoes, so you know the ones you are sent are the ones returned, not someone else’s heavily aged shoe with no prior knowledge of its historical workload. Better still, fit new shoes for continued safety and longevity.

It is very simple to replace the pads on disc brakes and the back plate can be disposed of accordingly. The disc brake is much easier to configure during initial setup and also after maintenance periods and pad renewals. There are more step and component checks on the drum brake when refitting new shoes compared to the disc.

Summary

It has been highlighted that the disc brake is the more expensive option i.e., initial purchase and the cost of replacement parts, yet it requires less maintenance time if the brakes are used regularly. However, the drum brake has proven to be the more resilient as it is better protected from the outside elements and the life of the shoes and drum seem to extend beyond that of disc and pads. Whilst drum brake components cost less, remember there are more components to replace.

Ultimately, it depends on the conditions the brakes will be subjected to, and the workloads encountered. There is no definitive answer when asking which brake set-up to use and opinions will always be divided.