BPW outlines the history of its Eco Hub System

BPW’s Eco hub system has been at the heart of trailer axles for 30 years. CVW looks back at its origins and development over that period.

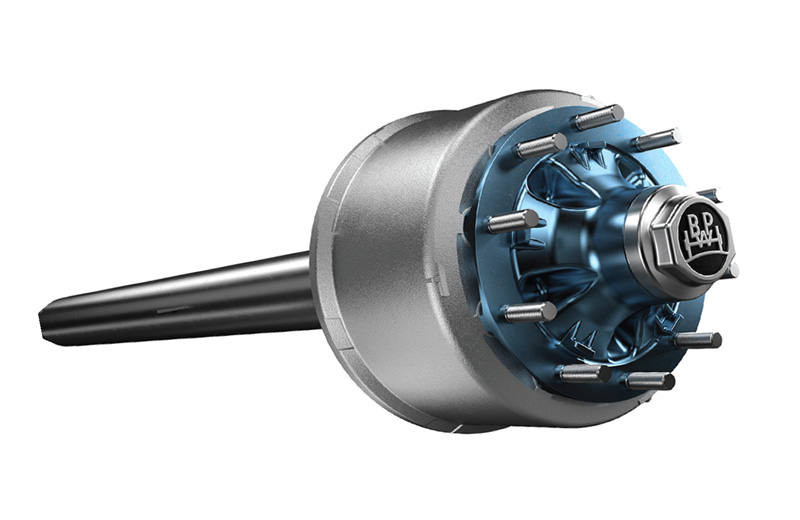

BPW is rightly celebrating the 30th anniversary of its patented Eco hub system. Since its introduction, the hub has become the go-to part in axle construction, consistently setting new benchmarks within the transport industry. Patented 30 years ago, the BPW Eco hub system has been a trailblazing success, and the Eco hub principle has been the foundation of BPW running gear developments ever since.

Specifically designed to cope with the high-duty cycles of modern transport, the hub’s clever construction is designed to boost mileage and cost efficiencies. Close attention has always been paid to key areas such as stub axle, bearing selection, sealing arrangement, lubrication development, and bearing adjustment.

Over the years BPW has introduced innovations to each generation of the Eco hub, seamlessly adapting to new technologies, including safety regulations and sustainability requirements. Its low-maintenance features allow operators to keep running costs to an absolute minimum, making it the solution of choice for fleet operators and trailer builders worldwide.

Unique mounting

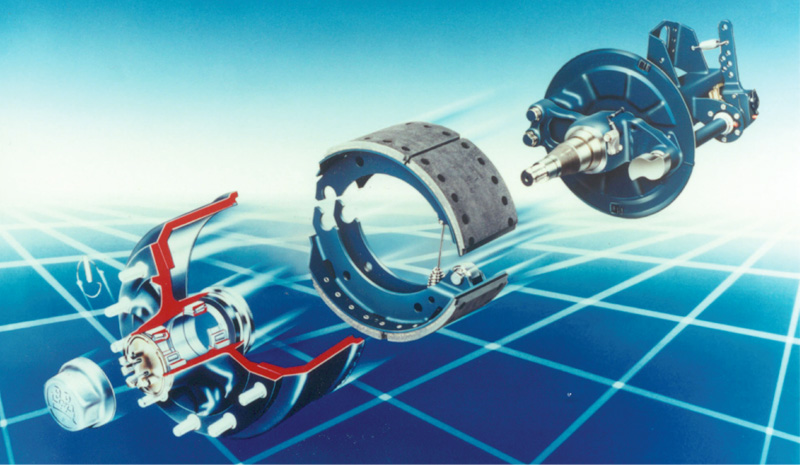

So what exactly made the hub unique? The BPW hub system uses a clever spindle nut that automatically compensates for any wear in the bearings. Each time the hub is removed or the spindle nut is released and re-torqued, it automatically takes up any wear in the wheel bearings and sets the bearing pre-load to the correct amount. This gives an advantage over a compact or cartridge bearing, where it is not possible to adjust out any wear in the bearing.

The heavy-duty DIN/ISO taper roller bearings, together with the grease seals, are retained in the hub using circlips. If necessary, the circlips can be easily removed to facilitate checking or replacing of the bearings. When the bearings need to be replaced, this can be achieved without having to separate the hub from the road wheel, brake drum, or disc. These commercially available taper roller bearings can be purchased as a repair kit and come complete with new circlips and grease seals.

It’s often the little things that make life easier. One of which is the hub spindle nut, which allows faster and easier removal of the wheel and reduces brake re-lining times by at least 50%. Inspired by the speed and efficiency of Formula One pit stops, the BPW hub nut acts as a puller, enabling the removal of the entire hub, brake drum and road wheel assembly, in one simple movement. The benefits include easier service and repair, shorter servicing times, reduced maintenance costs, and less downtime. Semi-trailers with the Eco hub unit typically spend less time in the workshop; each brake service is shortened by at least 10 operations.