Juratek Marketing Manager Matt Leeming explains why he thinks major bus operators choose to fit the company’s Synergy Braking range.

Like many in the commercial vehicle industry, UK bus and coach operators are facing ever increasing

challenges, with rising costs and more emphasis on safety. Choosing a braking product that is cost effective, safe and durable in all conditions can be a particularly difficult challenge.

Commercial vehicles experience a wide spectrum of use in service and this has a direct bearing on the duty to which their brake system is subjected and the operating temperatures that are reached. At the one end of the scale vehicles can be running up and down the motorway hardly ever applying their brakes, while some are required to constantly stop and start, others could be employed as tippers, and some operate on routes with long hill descents which involve continuous application of the brakes.

Brake temperature mapping of these different operating conditions, indicates temperatures that can range from the relatively low 200°C under light conditions all the way up to 850°C during long hill descents or urban bus routes.

Extended pad life

Basic pad grades, which are perfectly suitable up to medium levels of duty, wear at a much faster rate once the operating temperature exceeds 400°C for any length of time. Juratek says this is where a better,

premium, grade of pad, containing higher temperature wear resisting ingredients in its formulation becomes an advantage, providing the end user with a more cost effective fitment due to its extended pad life.

Higher temperatures and speeds can also result in thermal crazing and cracking of the brake disc, resulting in the need for the brake discs to be replaced to ensure safe operation. This is why the compatibility of the pad and disc is important, and needs to be included as a part of the brake pad development process.

If the pad is too hard or too stiff, the braking load and resulting temperature build-up will be more localised, rather than being distributed uniformly over the braking path. This could lead to ‘hot spots’ on the surface of the disc and eventual rupture (cracking), of the disc surface.

The development of brake pads and discs has to recognise, and cater, for all of these possible conditions to ensure that the resulting products that are offered for sale are safe, and durable. Juratek says that it is not really enough to just carry out the mandatory UN ECE R90 tests which cover the basic braking effectiveness and fade, but do not test for performance, durability and compatibility between brake pad and brake disc under the wide range of different service operating conditions.

Product development

Juratek says that many thousands of man hours go into developing a new product, which starts with small sample tests; the most promising materials from this work progressing to full scale inertia dynamometer tests at full axle loads.

The development objective at this stage is to measure and compare the effectiveness of the development grades with established materials over a range of different speeds, pressures and temperatures.

Wear testing at different disc temperatures then follows, together with an assessment of the compatibility of the material with the brake disc under different operating conditions to ensure the material does not cause thermal crazing, cracking or excessive wear of the disc. The most promising candidates from this work will then undergo field tests before a final selection is made for legal approval and offered for sale.

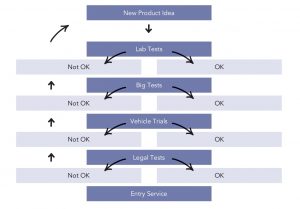

The process is shown in a simplified flow chart below:

Juratek says its Synergy products – Synergy Red (Premium) and Synergy Yellow (Premium Plus) both underwent this exhaustive, 24 month development process.

According to the company, both have a high performance level, which provides for shorter stopping distances, with excellent stability of performance with speed and pressure, coupled with long pad life and excellent working compatibility with the brake disc.