We can say with certainty that, in the future, haulage will be different than it is today. But are we able to predict what these changes may bring? Danny Broomfield, Sales Director of JOST UK, reflects on current trends and explains what we can expect over the next few years.

If I look back to the early days of my career, trucks and trucking were very different. Some of the changes I have seen were slow and steady, others were practically overnight. Driver aids are an obvious example of technology that is commonplace today, but was a mere figment of the imagination just a few decades ago. We’re still seeing developments in this area to the degree that truly autonomous vehicles now seem like an inevitability for the near future.

Technological change is often driven by outside influence, most commonly new laws and standards being introduced. Other drivers for change include new technologies crossing over from other industries or increased focus on corporate social responsibility for both the environment and safety. Not to mention the most common driver of them all – the pursuit of a competitive advantage through improved operational efficiency. In fact, these market influences are all linked at several different levels so can affect one another.

Possibly the most important change to our industry has been the massive improvements in health and safety brought about by new legislation and the introduction of modern technologies. Hauling large, heavy loads over long distances does carry an inherent risk for drivers, loading bay staff, and the general public. So, it’s right that efforts are always being made to improve. Such improvements take many forms – headline grabbing examples include cabs with improved visibility, introduction of disc brakes on trailers, and electronic sensors for fifth wheels and towing hitches.

Health and safety

However, there are other developments occurring under the radar that will improve driver comfort and safety for other road users. For an example of a new trend driven by a growing concern for health and safety, look no further than the humble electrically operated landing leg.

JOST originally developed these as a solution to improve productivity in quarries, seaports, and distribution centres, where landing legs are raised and lowered many times a day. However, they are now catching the eye of a number of operators of road-going fleets who see them as a solution to preventing repetitive strain injury and back problems for drivers, as well as ensuring that they are properly deployed and stowed each time.

Of course, whilst safety is important, the purpose of all commercial enterprises is profit. So, it’s hardly a surprise that many of the developments we see are geared towards improving the profitability of vehicles. One way to quickly make such improvements is to reduce vehicle weight, thus increasing payload. With emissions regulations leading to heavier power trains, body builders are working closely with manufacturers to develop components that can keep curb weight down.

One of the heaviest on-board systems used on tipper trucks, ejection trailers, and refuse compactors is the hydraulics – or ‘wet kits’ – so these are now being targeted for weight reduction programmes. Of course, it is not simply a matter of making them lighter; their performance levels must be at least maintained or, preferably, improved.

Edbro’s latest lightweight tipping systems work much faster than their predecessors, so there is an appreciable productivity gain. They are also designed to work at lower pressure so that smaller, more economical pumps can be used. This also reduces wear and tear, which increases component life expectancy and reduces maintenance costs.

Environment first

JOST also supports another long-term trend in haulage: the move to cleaner, more environmentally friendly solutions. The latest development in this area being the introduction of a bio-grease for fifth wheel couplings. This is a high-performance lubricant that is completely biodegradable and suitable for highly demanding duties.

With about 600,000 articulated trucks in Europe alone, each requiring about 10kg of grease a year, the potential for this product to improve the industry’s eco-footprint is substantial. To further encourage its uptake, JOST is offering it at the same price as conventional hydrocarbon-based lubricant.

The bio-grease is compatible with LubetTronic, an electronically controlled dispenser which automatically optimises consumption against usage. This reduces the tendency to over-lubricate, so can lead to a reduction in consumption of 15%-20%.

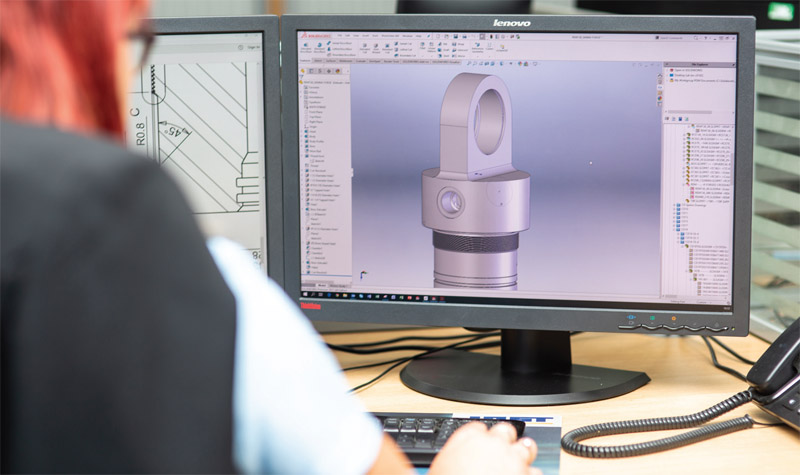

JOST has an excellent research and development team that is always working on updates and advances that reflect the changing demands of the industry. Put concisely, the focuses for the team are: reducing the weight of on-truck systems to increase load capacity and reduce fuel consumption; speeding up operations so that time is saved with every load; designing in safety and reducing risk; looking for ‘greener’ solutions; and adding intelligence through sensors, computers, and electronics.

Over the medium-term we can expect to see greater adoption of electronics and computers, technologies to protect personnel and the environment, and solutions that improve operational efficiency. JOST is proud of its track record in research and development and expects to remain an innovator the industry can rely on.