Common causes of turbocharger failure

David Eszenyi, commercial director of remanufacturer, Ivor Searle, examines the common causes of turbocharger failure and offers a solution.

With around 4.9 million primarily diesel vans in the UK’s motorparc and an average vehicle age of nine years, according to SMMT data, it’s clear that demand for replacement turbos continues to present a strong business opportunity for workshops.

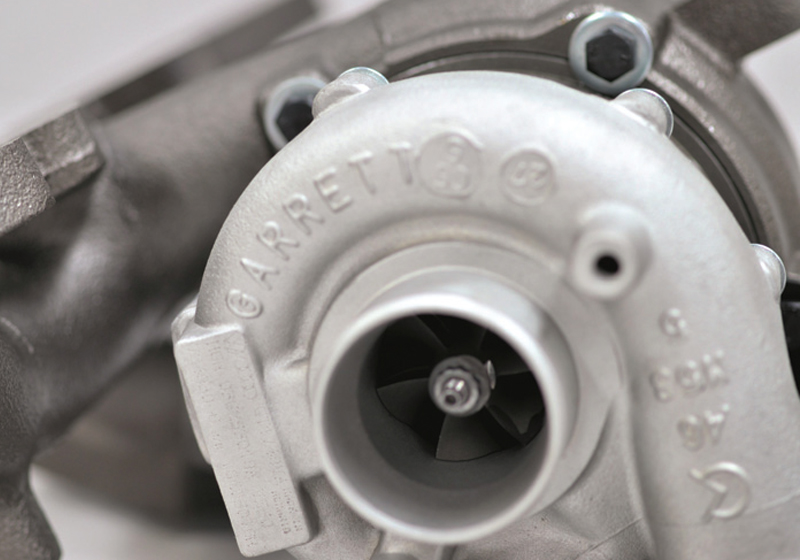

Although designed to last the lifetime of the vehicle, turbochargers are engineered to high tolerances, so a number of external factors can cause damage, leading to premature failure. Symptoms include a loud whining noise, power loss and slow acceleration, as well as difficulty maintaining high speeds, a smoking exhaust and illumination of the ‘check engine’ warning light in the instrument cluster. Based on our remanufacturing experience, we’ve identified some of common causes of turbocharger failure:

Oil and exhaust system contamination

Effective engine lubrication is critical for turbo operation, so a lack of oil, or use of the incorrect specification, can produce contaminants in the engine, that can contribute to turbo failure. Oil contamination, as well as carbon deposits from incomplete combustion, build up in the turbo over time, resulting in faults such as the vanes sticking in variable geometry turbos causing power loss.

Contamination can also be sent ‘upstream’ into the turbo due to problems in the exhaust system, such as a blocked or restricted DPF. Turbos are designed to handle high exhaust gas temperatures of around 800°C, so excess exhaust gas temperature beyond this point can also harm turbos, causing the turbine shaft to melt and, in some instances, detachment of the turbine wheels away from the shaft. With this in mind, we always recommend that workshops replacing a customer’s turbo always check the van’s DPF at the same time and, if needed, get it professionally cleaned.

Foreign objects

Foreign object debris, or FOD, can destroy a turbo in seconds. Occasionally, foreign objects, such as fragments of metal from broken engine components, dust particles, small stones and other debris can be ingested into the compressor or turbine inlet, resulting in it colliding with the compressor wheel that runs at over 100,000 rpm. Even the smallest particle hitting the compressor wheel can unbalance the turbo, causing catastrophic turbocharger failure.

Over speeding

Based on the principle of forced induction, turbos are designed to increase the air supply that feeds the engine. Over speeding occurs when the turbo rotates at a greater speed than its operational limits and beyond its safe parameters, eventually causing it to fail by damaging the turbine or compressor wheels and bearings. Leaks, cracks or damaged seals between the compressor and the engine can harm the turbo, making it operate beyond intended limits. Further causes of turbo failure include moisture ingress and wear and tear on high mileage vans and vehicles that have been subjected to harsh duty cycles.

Cost control

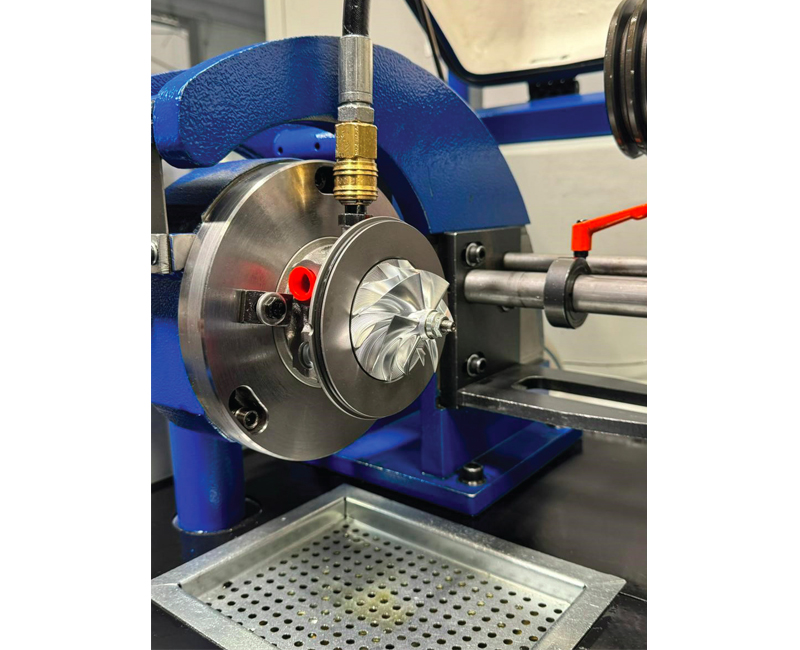

In many cases a replacement with a remanufactured turbo is the answer. For instance, at Ivor Searle, demand for our all makes programme of remanufactured LCV turbos continues to grow, not least because it is far more cost effective to buy a reman turbo than sourcing a brand-new OE unit. The saving can be as much as 40%. The turbo remanufacturing process involves a complete strip down of the unit and thorough cleansing using pyrolytic technology, after which all internal components are replaced.

All external housings are meticulously examined and checked against OE specification and any non-conforming components are also replaced. All our turbochargers undergo stringent quality checks and test procedures throughout the remanufacturing process to ensure maximum durability and service life. Prior to final assembly, the turbocharger’s rotating assembly is balanced on state-of-the-art VSR equipment to OE specification and oil flow rates are checked at the same time. Every turbo receives a detailed final inspection and is flow tested to ensure optimum performance.