In his first guest column for CVW, Toby Clark discusses where axles and suspensions are heading and the technology that workshops need to start looking out for.

Axles and suspensions seem like some of the simplest parts in a vehicle, and you might think that there hadn’t been much development in these components for a while – but environmental concerns, safety issues and driver shortages are making manufacturers look at new technology in every part of the vehicle. Here we look at some of the latest developments in truck and trailer axles and suspensions.

The ongoing driver shortage will put pressure on operators to increase payloads and load volumes; this means bigger trucks and trailers, which are tricky to manoeuvre in urban spaces. Rear-steer systems are increasingly fitted to trailers, and electrohydraulic command-steer systems offer more flexibility than oldfashioned turntable-based mechanical systems, without the complication of a fully-hydraulic system.

The new generation of trailer-steer systems use electronic sensors on the kingpin and the axles, connected to an ECU which controls actuators attached to steering knuckles on one or more trailer axles. The actuators are driven by an electrohydraulic pump, powered by the tractor’s electrics or from trailer-mounted batteries.

For example, VSE’s Advanced Steering setup can be fitted to up to three axles, and to any brand of axle up to 10 tonnes capacity. It allows for steering angles of up to 45 degrees, and can “crab steer”, with all the steering wheels parallel to each other. The weight penalty (around 160kg per axle) becomes less of an issue when you realise that potentially two 13.6m command-steer triaxle trailers could replace three 10.5m tandem-axle urban trailers.

TRIDEC’s EF-S electronic steering system is not intended for urban delivery use, but rather for trailers with low neck and kingpin heights, such as bulk tankers and low-loaders. It too offers crab steering, and a wireless remote steering option for tricky manoeuvres.

Low-chassis trailers such as doubledeckers are also driving innovation in axles and suspension. Some firms offer independent air suspension units, which allow a super-low floor – if the trailer structure is stiff enough.

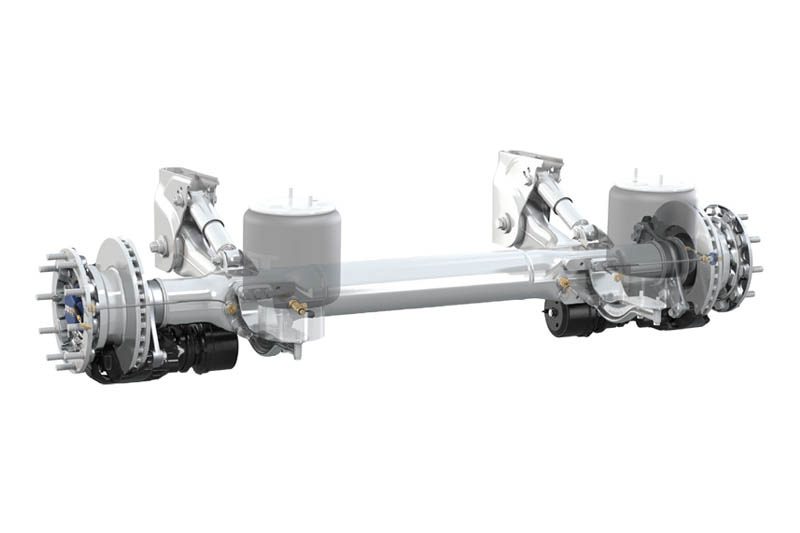

Others are refining conventional beam axles: for instance, Jost’s DCA Airmaster integrates compressed air reservoirs for brakes and air suspension into the crossmember, which frees up space beneath the trailer as well as (according to Jost) reducing weight by up to 50kg. The Airmaster axle is also compatible with Jost’s Plug & Play tyre inflation system, which can keep truck and trailer tyres inflated to the correct pressure on the move.

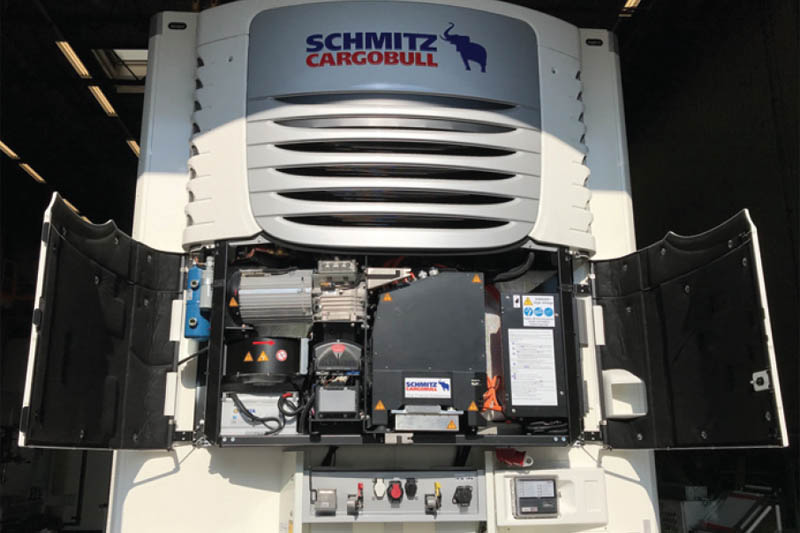

Diesel-powered fridge units in trailers are everywhere, but with the world going electric in so many ways, the noise and emissions of a diesel-powered reefer have become less acceptable – and the duty rebate for diesel used for fridges is due to be abolished in April 2022. A number of manufacturers have looked at using the trailer’s own wheels to generate power for the fridge, including Carrier Transicold, Schmitz Cargobull, BPW, and Thermo King.

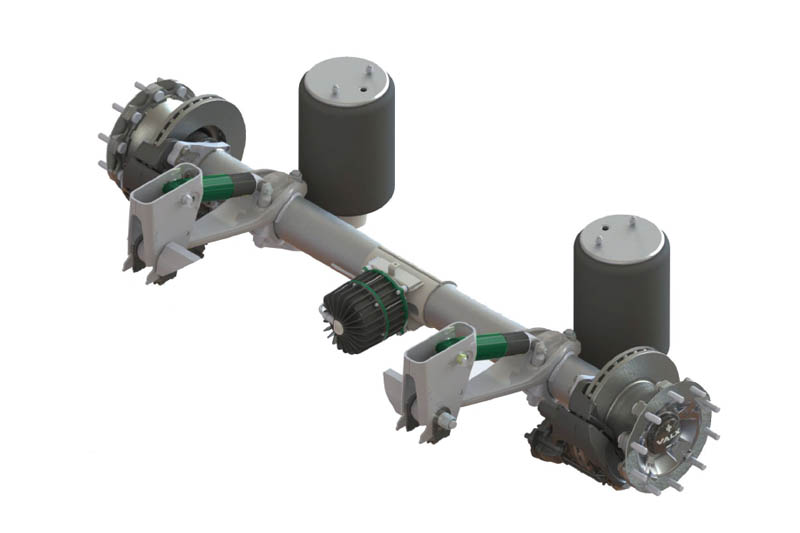

Carrier’s Vector eCool system combines its E-Drive electric refrigeration units with an ‘electric axle’ which has a built-in generator used to charge a battery pack. Gray & Adams has an eCool demonstrator trailer fitted with the Valx E2! [sic] ‘Energy axle’, which can generate up to 650W and weighs just 17kg more than a conventional axle. Even with the battery pack fitted, the whole setup is said to be ‘significantly lighter’ than a standard diesel unit with a full tank of fuel. When the trailer is parked the eCool system can be plugged into the mains to fully charge in under four hours.

Schmitz Cargobull is also demonstrating its S.KOe ‘zero emissions’ electric reefer trailer, which has entered service with a German haulier. This is equipped with the firm’s own ROTOS eAxle, and an intelligent charging system which allows the axle to provide a certain amount of regenerative braking when it is required.

Schmitz is not the only trailer builder making its own axles and suspensions: Bavarian firm Kögel recently launched the KTA NOVUM, with the goals of “uncompromising quality, high costefficiency and optimal maintenance-friendliness”. The main feature is a new axle mounting, designed to “optimally transfer force to the side member”, while weight-saving features include direct clamping of the axle by the wishbones, and a reduced number of fasteners.

Meanwhile, ZF is working on an electronic active suspension system for truck cabs, called cCAB; this independently moves each corner of the cab using electrohydraulic actuators, as ZF puts it, ‘anticipating undesired movements and pre-emptively working against them’. One of the ideas with this is that with self-driving trucks, the cab will be so stable that it can be used as a mobile office on the move.