Sticking to trailer weight tolerances is of crucial importance, so Doctor Air Brake explores what you should bear in mind and how its Trailer Weigh system can lighten the load.

There is so much focus on payload with all the manufacturers claiming the greatest capabilities, yet little focus on the operator and/or driver making sure the driver and operator stay within both the legal and vehicle limits and capabilities.

When overloading a vehicle, you invalidate the warranty as a minimum, but more importantly, you expose the public and other road users to a vehicle on the public highway that is beyond its roadworthiness. This is just one reason we often see VOSA pulling over goods vehicles of all size, as they need to make sure the vehicle is within its weight tolerances, along with other checks they deem applicable.

You should also think about the extra burden you impose on the vehicle’s suspension and tyres, let alone the extra wear and tear on brake and clutch faces which will, in the long-term, cost more with the extra maintenance, etc.

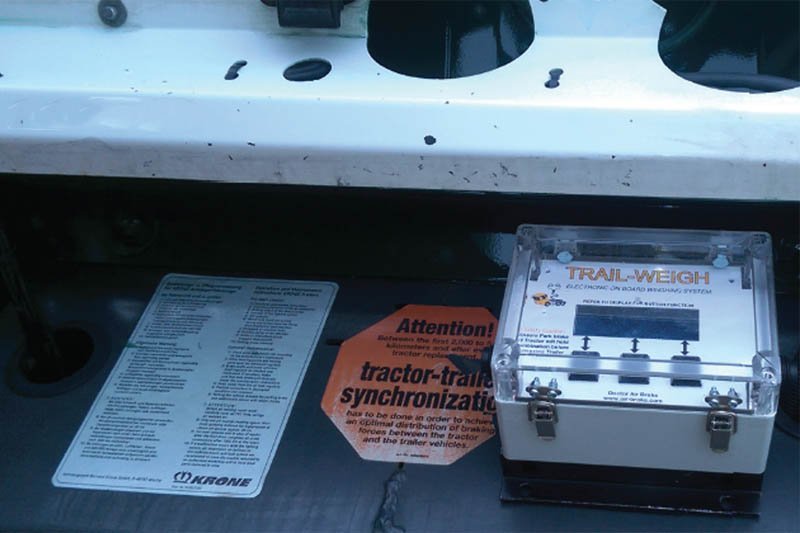

Previously, the operator would have to take a tractor unit and trailer to a weigh bridge, so they know the GVM (Gross Vehicle Mass) and/or the tare weight. Doctor Air Brake, traditionally renowned for its driver systems – including one that is now mandatory on all 18 tonne and above crash cushion vehicles in the UK and many other countries – has now designed a system that will tell the operator what weight is loaded onto the trailer by using the pressure sensor inside the EBS system’s ECU.

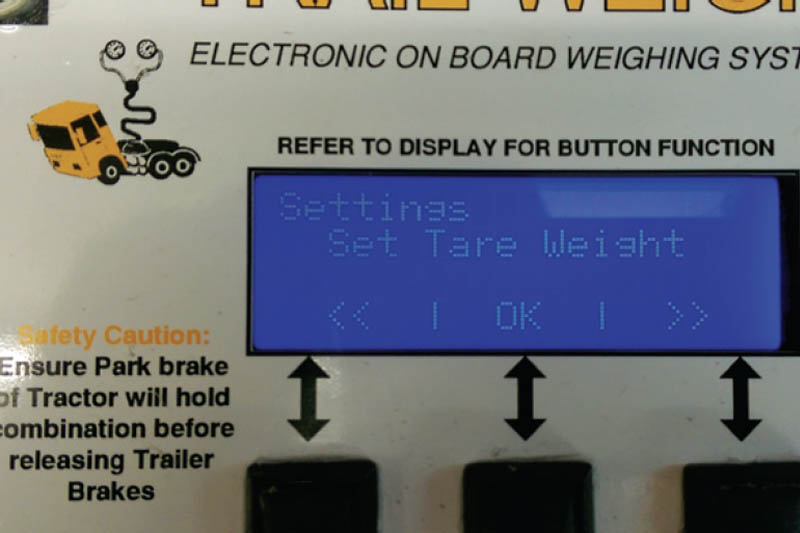

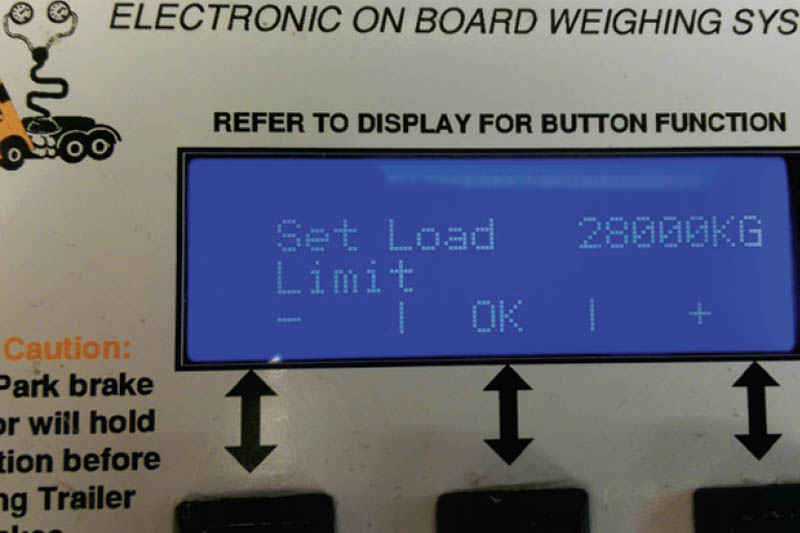

A trailer ECU has to know how much weight is on the trailer to control the brakes, so this gives an accurate measure and allows a better knowledge of payload on board. The system can have trailer-mounted display as well as an in-cab display system, allowing the driver to check, while the vehicle is being loaded, in the safety of his cab, while also being able to check when physically at the side of the vehicle.

The Doctor Air Brake system will automatically release only the trailers brakes for two seconds to allow the trailer’s air bags time to settle out, so the reading is more accurate, as well as allowing the load to settle a little.

Using this type of system allows the operator and the driver to make sure they are compliant, which again in today’s world of health and safety is not just important, it’s vital! When you consider the financial impact on an individual and the business of a hefty fine and, as mentioned above, the extra maintenance and potential VOR costs involved in running vehicles, it’s never worth the risk.

There is obviously the burning question in all these types of systems: price. Crucially, this should never be at the detriment of health and safety. Other systems will include adding additional sensors etc. so they can monitor the vehicles GVM or payload adding to their overall price, which can be anywhere from £1,500 to £2,500 or more. The Doctor Air Brake system utilises mostly the vehicle’s own systems and sensors which are more reliable and accurate.

So, the company can retail its product at a much lower cost, starting off at approximately £899, inc. fitting (depending on make and model and ECO on the trailer). Again, this saves the operator valuable money, and allows the operator to spend the resulting saving on other important items from their H&S budget.