Eminox discusses the range of measures being introduced to combat climate change and the ways in which operators can ensure they comply with them.

The recent COP26 summit in Glasgow has increased the focus on moving to a zero carbon future. This shift includes reducing heavy-duty vehicle emissions, particularly in urban areas, to lower pollution, improve air quality and safeguard the environment.

As part of this, cities across the UK are introducing Clean Air Zones (CAZ) and Low Emission Zones (LEZ), bringing tighter standards for emissions around nitrogen oxides (NOx) and particulate matter (PM) – and charging non-compliant vehicles.

The rise of Clean Air Zones

Portsmouth is the latest city to launch a CAZ, starting on 29th November 2021, with heavy goods vehicles that don’t meet the Euro VI emissions standards being charged £50 per day to enter its zone. Portsmouth joins the likes of Bath, Birmingham, Oxford, and London in bringing in tighter standards, with Transport for Greater Manchester introducing a CAZ for Greater Manchester from 30th May 2022.

The health benefits are clear – a study commissioned by the Greater London Authority found that its Ultra Low Emission Zone (ULEZ) will save the NHS £4.17 billion by 2050 by reducing air pollution-related diseases by nearly 30%.

Ensuring cost-effective compliance

The newest commercial diesel vehicles that meet the Euro VI emissions regulations are normally exempt from CAZ charges. However, operators of older trucks, buses and coaches that may still have many years of operating life ahead of them will need to pay, adding substantially to operating costs.

Alternatively, they will be forced to juggle their fleets, only using non-compliant vehicles outside Clean Air Zones, adding another level of complexity to route planning. Replacing these vehicles is simply not cost-effective, particularly with many companies still coping with the financial impact of the pandemic and lockdowns.

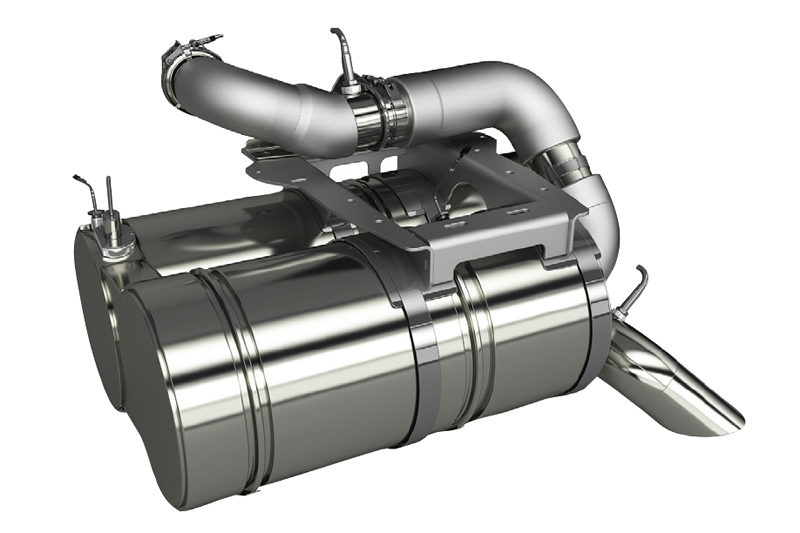

The answer is to retrofit emissions control technology to these existing vehicles, prolonging their life, boosting their value, ensuring compliance and reducing pollution. By fitting an approved exhaust aftertreatment system (EATS) to an older vehicle operators can achieve Euro VI equivalent emissions standards.

Retrofit removes the need to make immediate major investments in new vehicles or be forced to wait for their delivery. Your vehicle is quickly back on the road, with fitting requiring minimal downtime. In fact, on average, 10-15 heavy duty diesel vehicles can be retrofitted for the price of buying a new one.

Working together to ensure compliance

When choosing a retrofit solution, it is vital to invest in an approved, high quality solution. To ensure compliance, your Euro VI retrofit EATS must be certified by the government-backed Clean Vehicle Retrofit Accreditation Scheme (CVRAS), run by the Energy Saving Trust. Certification involves a comprehensive independent testing programme before manufacturers receive approval for their emissions reduction system, which is specific to vehicle/engine combinations.

For over 42 years, Eminox has been designing and manufacturing high-quality emissions control systems, for both the retrofit and automotive Original Equipment Manufacturer (OEM) market. It was first to market with CVRAS approved systems for buses, coaches, trucks and refuse collection vehicles and supplies emissions reduction technology to leading OEMs including Iveco and Volvo.

Altogether over 85,000 Eminox solutions have been sold and distributed around the world, making it the most widely used retrofit emissions control system globally. The company has worked on key projects such as the £86 million Transport for London (TfL) project to upgrade 5,000 buses to Euro VI equivalent standards, as well as the Scottish Government’s Bus Emission Abatement Retrofit (BEAR) Fund. Over the last 10 years, Eminox’s retrofit solutions have prevented over 25,000 tonnes of NOx from entering the atmosphere, which is a cost of society public health saving of £631 million.

Focused on the customer

Through its experience, Eminox has built a strong understanding of the complexity of designing and manufacturing retrofit systems that meet the stringent real-world demands that fleet operators have. Consequently, its EMx E6 technology has been shown to reduce PM, NOx, NO2, CO and hydrocarbons by up to 99%, even at the low operating temperatures that many vehicles running in urban areas face.

Quality is central to Eminox solutions. The company has invested heavily in UK design, manufacturing, and support facilities to deliver a seamless solution to customers. All Eminox exhaust aftertreatment systems are designed and manufactured at its Lincolnshire headquarters.

This end-to-end approach continues across the lifetime of retrofit solutions. Eminox’s in-house team has deep experience in supporting large national fleets to maintain peak efficiency, and provides tailored aftersales support to ensure operators continue to receive the best results from their retrofit exhaust aftertreatment system.

Operators understand the regulatory and ethical need to move towards a net zero future, but also have to preserve their existing investments in high-value vehicles. Through Eminox’s high-quality, cost-effective and CVRAS-approved retrofit solutions they can achieve both objectives, reducing emissions and improving air quality while removing the need to scrap existing vehicles.