Dr Dave Phillips, engineering director at Eminox, explains how Diesel Particulate Filters (DPFs) work and why you should react to DPF warning lights to ensure emissions compliance is maintained.

Any dashboard warning light can be a cause for concern, and the general rule is that should a light appear, professional advice should be sought as soon as is practicable. This applies when a DPF warning light presents itself, especially due to the negative impact it could have on emissions compliance.

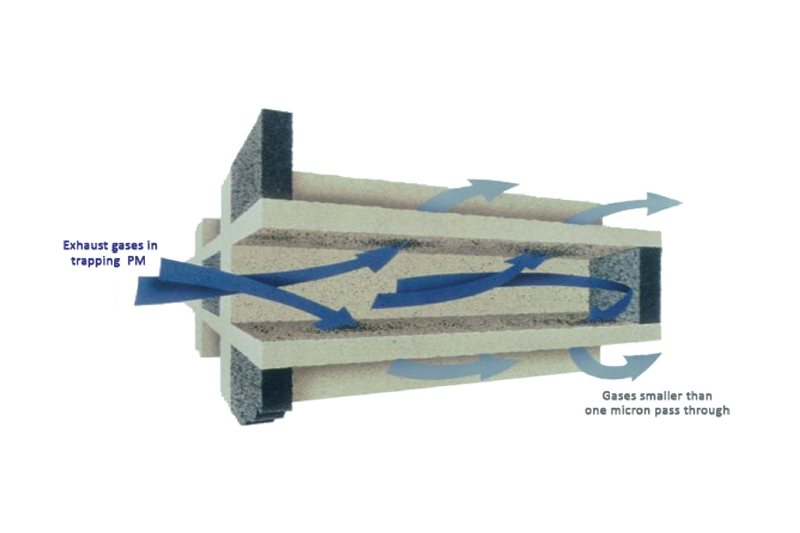

A DPF works in a very harsh environment and eliminates the Particulate Matter (PM) by burning it off as it passes through the filter in a self-cleaning process known as regeneration. Understanding how this process works clarifies how it impacts on reducing vehicle emissions.

Regeneration is achieved when the vehicle has been running long enough and at a high enough temperature and is key to the efficient functioning of the DPF. There are two types of regeneration: active and passive.

Active regeneration systems inject fuel (diesel) directly into the exhaust stream which is ignited inside the DPF. This raises the temperature to burn out soot, releasing the trapped carbon as CO2. Passive regeneration relies upon the presence of NO2 (Nitrogen Dioxide) in the exhaust.

The key to optimised performance

In addition to regeneration, the key to optimised performance for DPFs is the material that is used to manufacture them.

There are two types of material used separately in the manufacture of DPFs; Silicon Carbide and Cordierite with both being referred to as Ceramic. The DPF (which is a honeycomb structure) is typically encased in an outer drum made from stainless steel. The differences between the two materials are primarily defined by their individual benefits and challenges such as their tolerance to high temperatures and their cost.

Silicon Carbide (SiC) is easily identified as a dark grey colour. Extremely tough, it has a very high melting point (c. 2650°C). Larger DPFs are made in segments to prevent failure under everyday usage.

Cordierite is made of Aluminium Magnesium Silicate and is cream in colour. In comparison, Cordierite has a lower melting point (around 1450°C) and is more porous than SiC. With expansion much less significant, DPFs can be made in larger, single blocks.

A quality DPF has the additional benefit of a Euro 6 wash coat which adds Platinum (and Palladium) catalytic material to the walls of the DPF, increasing functionality of the Diesel Oxidation Catalyst (DOC) to the DPF. As part of the DOC functionality is to oxidise NO into NO2, this improves regeneration characteristics.

Warning lights and the implication on emissions

By their nature, all DPFs will need to be replaced at some point and ignoring warning lights can have a detrimental impact on both vehicle performance and business operations. Perhaps the most common reason for a DPF warning light to appear is because of a blocked DPF. This happens when the filter can no longer work efficiently at removing the PM or soot from the exhaust system, and as a result the performance of the vehicle can be compromised.

Identifying factors, in addition to a dashboard warning light, which hinder the performance of the vehicle could include:

- Loss of engine power

- The emission of black exhaust smoke

- Unusual engine smells

Equally as important as vehicle performance, and maximising its longevity, is the negative impact a compromised DPF will have on reducing emissions.

Driving a commercial vehicle without the required emissions control could compromise the legal compliance of the vehicle if stopped or tested. This is particularly important when driving in an Ultra-Low Emission or Clean Air Zone (ULEZ or CAZ) and hefty fines can be applied for non-compliance.

With a Euro 6 compliant DPF removing as much as 98-99% of tailpipe particles, it is not hard to see why DPF failure can deliver such negative impacts on emissions compliance and public health.

Future compliance

The introduction of Euro VII, expected in 2027, will address both the testing measures and the stringency of those measures for trucks and buses and, will be an important stepping stone in reaching the European Union 2050 net zero emissions targets. It is expected that the focus will specifically tackle the danger to public health that emissions from vehicles still pose.

Whilst Euro VI has, and Euro VII will help make significant improvements to emissions from vehicles powered by Internal Combustion Engines (ICE), Eminox, as a leading designer and manufacturer of technologies for a greener future, is also developing solutions to integrate alternative fuels and hybridisation alongside diesel powered solutions to future proof the commercial vehicle sector.