Replacing and repairing wheel bearings can often be a long, messy and time-consuming job for a technician. CVW recently visited wheel bearing manufacturer, Schaeffler, to learn more about its solution aimed at simplifying the procedure.

The FAG SmartSET from Schaeffler is a ready-to-fit wheel bearing repair solution for trucks and trailers. Pre- assembled, pre-greased and pre-positioned, it is the ideal problem- solver for UK independent garage workshops that work on Heavy Commercial Vehicles.

The FAG SmartSET is designed to reduce repair related downtime to a minimum, making assembling and greasing unnecessary. It is estimated that workshops can save up to two hours per axle with every FAG SmartSET repair, compared with conventional tapered roller bearings.

Pre-positioned rolling elements, and the sliding fit of the FAG SmartSET, make wheel bearing repairs a true ‘one man job’. The reduced assembly time can offer workshops an opportunity to increase revenue, with more jobs able to come through the workshop.

The product is designed to remove the chance of fitting failures, but it also increases the service life of the bearings and reduces wear related repairs.

FAG SmartSET is practical too, it can be used on most brands – for all commercial vehicle and trailer axle types – with oil or grease lubrication. Delivered as a ready-to- install kit, it features inboard and outboard bearing units.

Each SmartSET includes special fitting tools, making the need to purchase additional special tools unnecessary.

Malcolm Short, Technical Services Manager for Schaeffler Automotive Aftermarket in the UK, says: “The new FAG SmartSET is the perfect wheel bearing repair solution for all technicians who work on HCVs that enter their independent garage workshops.

“The FAG SmartSET bearing unit is pre- assembled at the factory, simplifying installation, and the pre-greased bearings guarantee the correct specification and amount of grease is used.

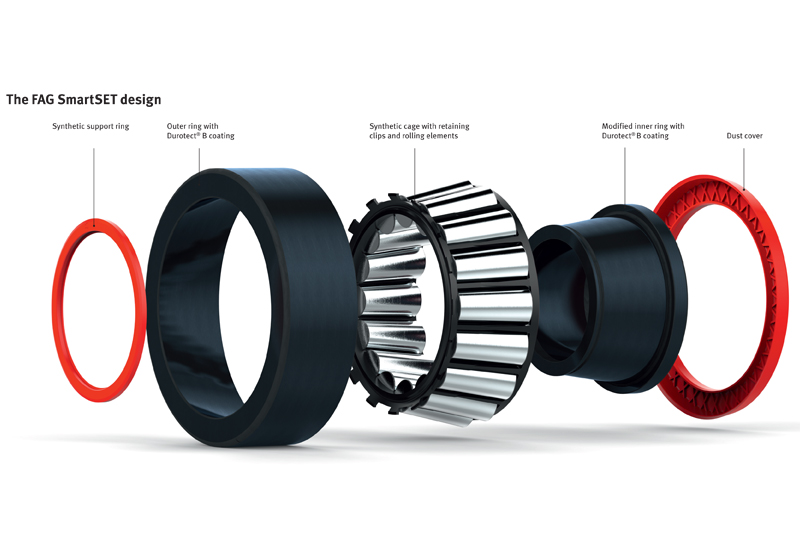

“The rolling elements are pre-positioned by a support ring, which eliminates additional wheel rotation when adjusting the bearing, and the FAG SmartSET also features a sliding fit, which prevents the hub from tilting during assembly.

“Installation errors, such as using the wrong specification, or amount of grease, are eliminated with the FAG SmartSET.”

FAG SmartSet features:

- A dust cover, which eliminates grease contamination by preventing dirt ingress

- Durotect B coating, designed to protect against corrosion as well as preventing slip damage and the formation of micro cracks

- A supplied fitting tool, aimed at making installation both simple and safe

The product has been developed exclusively for the aftermarket to meet the needs of the modern workshop, with the service lifetime being double that of a conventional tapered roller bearing, the company says.

Schaeffler says using a SmartSET will save one wheel bearing repair during a truck’s service life, and reduces the time needed for each subsequent repair, making it great news for distributors, workshops and fleet operators alike.