Sourcing CV replacement parts can be a tricky task, especially when guaranteeing the quality and authenticity of what you are purchasing. Dave Burgess of DB Auto Consultancy explains one particular tool on which his company has come to rely: the TecDoc Catalogue.

Dave Burgess is a relative newcomer to the commercial vehicle sector, but he has a wealth of experience in the automotive industry, having been in the trade for more than 30 years. His company, DB Auto Consultancy, is an active member of the United Aftermarket Network (UAN).

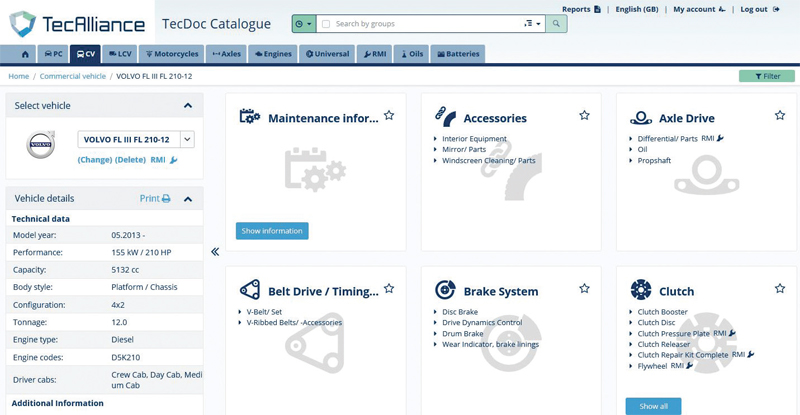

The TecDoc Catalogue from TecAlliance includes more than 110,000 vehicles models, data for 6.6 million products from over 700 brands, 254 million links, and 48 product groups. Its goal? To provide high quality replacement parts information and data for the independent aftermarket.

“The biggest single benefit that the TecDoc Catalogue has brought my business is to reduce our part returns to virtually zero,” explains Burgess. “This has naturally made a huge difference to our overall efficiencies, as well as directly to the bottom line.

“As all wholesalers will be very aware, part returns and the problems they create, as well as the costs they subject a business to, are some of the fundamental issues when it comes to profitability, particularly in an industry as fiercely competitive as ours and with such small profit margins.

“The specific nature of the search criteria, combined with the accuracy of the data in the TecDoc Catalogue, allows us to precisely identify the correct replacement item. This means, for example, that we don’t have to supply more than one part reference to cover the possible options. Having established the gains that the system has made possible, I simply couldn’t run my business now without the TecDoc Catalogue.”

This ongoing experience, and the requirement to ensure the business maintained its reputation for supplying the correct parts on demand, meant that the use of the TecDoc Catalogue was without question when Dave opened the doors of his CV-focused venture 18 months ago.

“I didn’t hesitate to use TecDoc data for the CV business. We initially used the existing platform that we had successfully adopted for the automotive business,” Burgess continues. “However, although the system listed the relevant service, repair, and accident-related replacement parts the business relies on, it was not quite so easy to navigate for CV searches, due to the fact that the historic links to the reference information associated with CVs were not quite as refined as they are for the automotive data.”

Recognising this point, and intent on making the parts data held within the system equally accessible to CV specialists as it is for the automotive community, the TecAlliance team embarked on creating a specialised CV version of the catalogue. During the final testing phase, Dave was invited to pilot the new ‘TecDoc VIN Catalogue – Truck’ to provide feedback and actively contribute to its ongoing development.

“Although the new system uses the vehicle’s chassis number to identify the vehicle, as well as to a certain extent the registration number, the TecDoc VIN Catalogue for Trucks is now as easy to use and reliable as the automotive version. This method still identifies the precise vehicle and the associated original equipment part numbers for its various components,” expands Burgess.

“From this information, TecDoc’s official data suppliers match their products, and this allows us, as a catalogue user, to choose the ideal replacement part for our customers, from a broad range of suppliers.

“From their perspective, the benefits are two-fold: first, just as part returns are what we as a wholesaler want to minimise, vehicle downtime is the biggest threat to our customers’ profitability, because a stranded vehicle simply becomes a cost. So, being able to quickly identify the correct part from a choice of suppliers allows us to source the replacement in the shortest timeframe and reduce the period the vehicle is out of service.

“The second benefit, although not directly visible to the customer, is the ability to interrogate the stock level at each supplier through TecAlliance’s order-to-invoice processing platform, Order Manager. This ensures that we can find a replacement that is available from stock and deliver it to the customer as quickly and efficiently as is possible, which again minimises both inconvenience and cost, and allows us to provide a first class service to our customers.”