febi explains the important role that ABS sensors and rings play in preventing commercial vehicle brakes from jamming.

ABS, ESP, ASR: nowadays, commercial vehicles are packed with driver assistance systems. For these to function, they require data from a wide variety of sensors in the vehicle. An example of such data includes the precise wheel speed of all braked wheels. This collection of data is the only way the control units can perform their calculations precisely in a fraction of a second.

If a wheel speed sensor fails, a malfunction is signalled to the driver and the systems no longer operate the way they were designed to. ABS, EBS, and many other systems are then rendered inactive. This can lead to wheel lock-up or the appearance of false alarms. In addition, the ABS indicator lights up and a fault is stored in the control unit.

Sascha Keller, Technical Marketing Manager at Ferdinand Bilstein, explains: “A defect in the ABS system should be repaired immediately since driving safety is impaired as a result.” Under its febi brand, the company offers a large number of components for the ABS system.

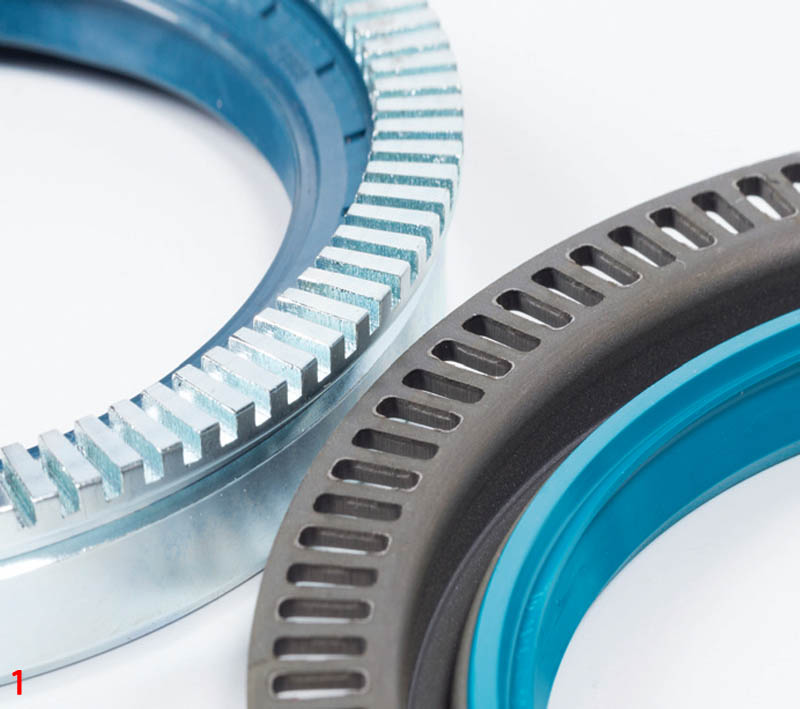

ABS ring

The ABS ring and the ABS sensor – also known as the speed sensor – are responsible for the generation of signals. There is a distinction between active and passive sensors. “In the commercial vehicle sector, passive sensors are used to a great extent; active sensors play only a subordinate role,” comments Sascha Keller.

The sensor ring is available in a variety of designs: as a sheet metal piece or made of solid material, as shown in Fig. 1. In many cases, the shaft seal is attached to the seal of the wheel hub or the sensor ring is included in the casting of the brake disc. As a rule, commercial vehicle sensor rings have 100 teeth.

ABS sensor

The ABS sensor is mounted directly in front of the sensor ring. The ABS ring is connected to a rotating part – such as the brake disc or the wheel hub, as shown in Fig. 2. Inside the sensor, there is a pole pin surrounded by a coil in contact with a permanent magnet. The magnetic field of this structure reaches to the sensor ring and detects through the fluctuation of the magnetic field if a tooth or a tooth gap of the sensor ring is in the magnetic field. If the magnetic field changes, a low alternating voltage is generated in the coil whose frequency and amplitudes serve as a speed signal for the control units. In contrast to the active sensors, the passive sensors do not require their own power supply from the control unit.

Repair of a faulty ABS sensor

A failure of the ABS sensor can be caused by various factors – for example:

- Short-circuit or disconnection

- Mechanical damage to the sensor or sensor ring

- Sensor is loose as the sleeve is heavily corroded

- Heavy contamination

- Wheel bearing clearance too large

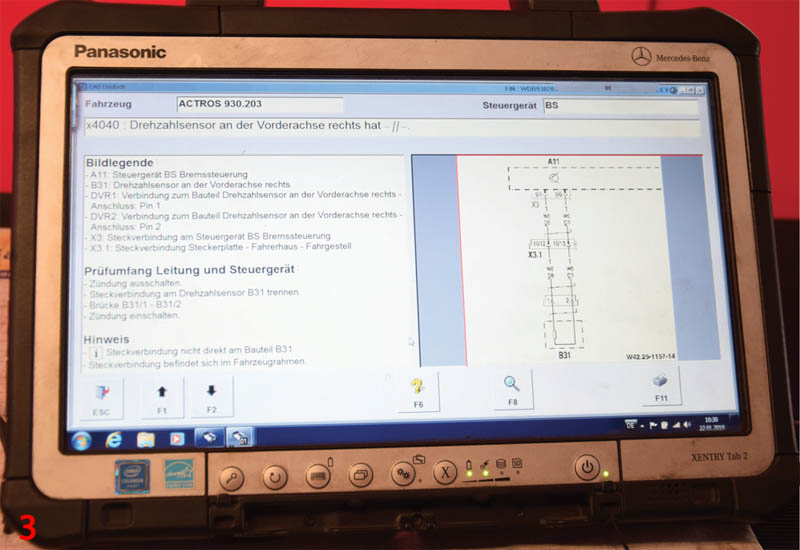

Troubleshooting

When searching for the cause of a failed ABS sensor, the fault memory should first be accessed (Fig. 3). After that has been done, the possible fault should be localised further with the aid of a diagnostic device.

“All cables and plug connections should then be checked and inspected for mechanical damage,” explains Keller.

Replacing an ABS sensor

To replace an ABS sensor, proceed with the following steps:

- Disconnect the cable of the defective ABS sensor from the plug

- Pull the sensor out of the bore – it may be necessary to remove the wheel hub for better access

- If the defective sensor has been removed, the bore must be cleaned and freed of rust

- The bore and the sleeve are then greased (this prevents premature corrosion). Now the sleeve is pushed into the bore. Thereafter, the sensor head is pushed into the sleeve until it touches the sensor ring. Due to the wheel bearing clearance and the movement of the wheel, the distance between the sensor and the sensor ring adjusts automatically. febi ABS sensors are always supplied with the sleeve and the grease – this means that everything is available for changing the sensor

- Finally, the plug connection must be closed again and the cables laid properly. After everything has been accomplished, the error can be deleted from the error memory.