Juratek takes CVW through the history and importance of the ECER90 regulations, and how it uses them to produce top quality components for the commercial vehicle sector.

It’s been 20 years since the ECER90 safety regulation was introduced for replacement disc brake pads and drum brake linings. The aim was to establish a common minimum standard of braking performance, product integrity, and manufactured quality for replacement brake linings across the whole of Europe. Prior to the introduction of ECER90, the market was unregulated and products of dubious quality could be sold with impunity, posing safety risks to all road users.

The benefits of the regulation were quickly recognised outside of Europe and, as a result, many other countries worldwide have also adopted this as their safety standard for replacement braking parts. Consequently, the regulation is not just an EU regulation, but a UN one, known as UNECER90.

Once UNECER90 had been implemented for brake linings, attention was turned to the other element of the braking couple: the brake disc and drum. These are also safety critical components, which, prior to the legislation, had no regulatory standards to control their performance, integrity, or manufactured quality.

To respond to this, a working group was formed to develop an extension to UNECER90 to include brake discs and drums. The outcome of five years of vigorous discussion and testing finally resulted in the 02 series of amendments to UNECER90, which is now in force. It applies to replacement brake discs for trucks, buses, and trailers whose brake systems were type approved after 1st November 2014.

Taking advantage

Whilst brake discs for vehicles type approved before this date do not need a legal approval, there is clearly merit in showing that the whole range of brake discs that you provide meets the legislative requirements and safety standards. This is why over 95% of Juratek’s range of CV brake discs are now UNECER90:02 approved.

The approval for replacement brake discs and drums follows the same concept as replacement brake linings. Performance checks ensure that the part meets the requirements of Regulation 13, the braking regulation that all new vehicles must meet before they can be sold on the market.

Then come the structural integrity tests. These tests, including the thermal fatigue test in particular, lie at the heart of UNECER90:02 for replacement brake discs and drums. They are designed to ensure that replacement parts match the capability of OE parts in dissipating high levels of braking energy, without excessive cracking or structural failure. As with brake linings, replacement brake discs and drums will carry the “E” approval mark, which will be of the following general form: E11 02 C 0359 7248. “E11” in this case indicates approval by the UK.

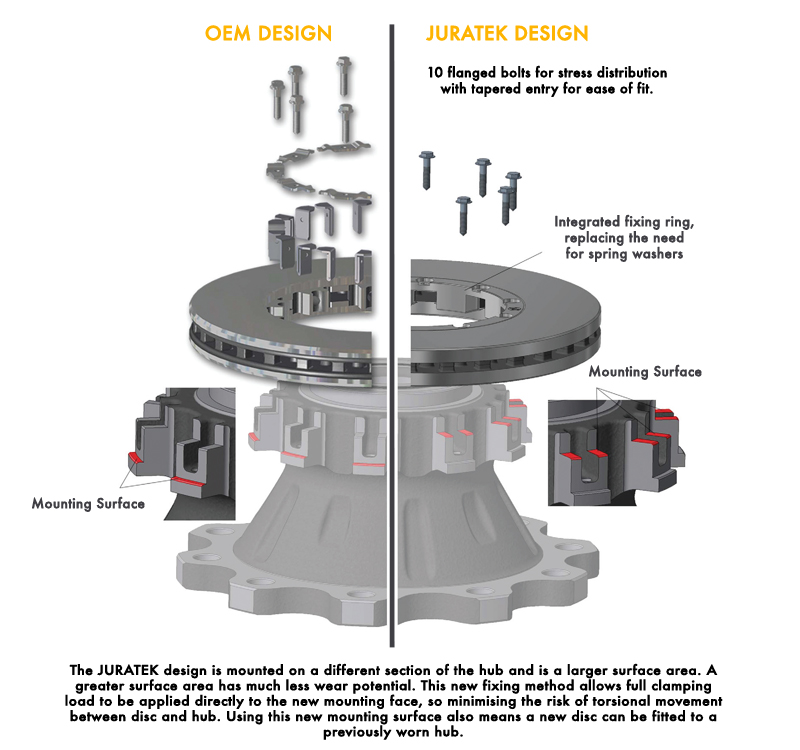

In addition to the exacting standards imposed by the UNECER90 regulations, Juratek also looks for ways to improve on existing OEM design. The latest version of the DAF111D, for example, is a case in point. The original design consists of a complicated fitting kit to attach the braking ring to the hub. So as not to infringe on the original patented design, Juratek has reengineered the disc, which differs from others in the aftermarket.

Whilst other versions contain discs that fit on the same mounting surface as the original, Juratek’s design fits on a different plane of the hub, and claims that this prevents the hub from wearing over time.

When fitted to a new or un-worn hub brake disc, the fit is perfect, but this is not usually the case for installation on a worn hub. This is where Juratek’s design shows its advantage – fitting to a worn hub is no problem, as the surface it is being fitted to is free of wear. This also saves the cost of having to replace a worn component, which can typically be around £500 per hub.