We spoke to Steve Smith, National Sales Manager ART of Mirka UK, about the company’s abrasive solutions and the challenges it faces.

Q. How have Mirka’s abrasives evolved over the last decade or so to meet the demands of the industry?

Steve Smith (SS): As with everything in life, change is a certainty and as a business you have to adapt to these changes. The CV sector is no different to any other with new technologies evolving within vehicle repairs and refinishing. The customer’s expectations are for the manufacturer’s R&D to meet these demands and new challenges, this is an area within Mirka given a high priority status.

Q. How has Mirka had to adapt to meet the current challenges?

SS: By working closely with the customer and understanding their needs and challenges, Mirka set to work on providing solutions to ensure the customer can tackle any given sanding application with confidence.

Q. What do you see on the horizon when it comes to abrasive evolution? And what is the most popular abrasive?

SS: The requirement for abrasives within the repair process is a key factor and unlikely to change in the foreseeable future, however new technologies will drive any change. PSA discs in roll format, which have been around for many years, are still one of the most popular products used within the CV sector today, especially with vehicle refurbishments, whilst cost is certainly an influencing factor.

Q. How does Mirka ensure that it can meet the demands of users in the CV sector?

SS: Working hand-in-hand with your partners is key, the need to understand their requirements, challenges, and frustrations, then by working together to ensure all these demands are met.

Q. What are the benefits of Mirka’s abrasives for end users in the CV sector?

SS: Benefits to the end user from using Mirka abrasives is having the peace of mind that the quality and performance of the products is consistent throughout. The end user also has access to our experienced technical team, the technical team cover everything from problem solving through to training, process, product, and profitability to ensure maximum benefits are gained from using the Mirka products and systems.

Just the trick

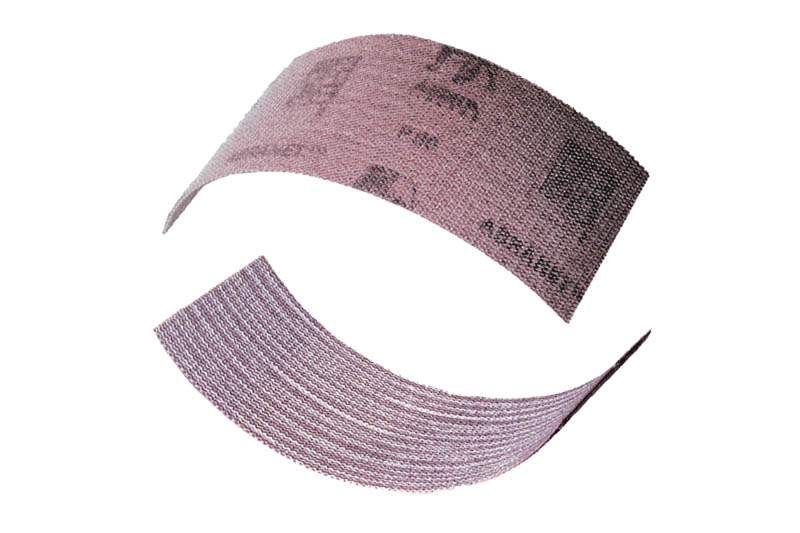

For two decades, Mirka has been at the forefront of dust-free sanding, thanks to an invention that revolutionised workplaces all around the world. By developing an abrasive that features a net structure instead of a conventional paper backing, Mirka was able to introduce extremely efficient on-tool dust removal that improves both the work quality and working environment. Mirka simply called the new abrasive Abranet.

Manufactured with Mirka’s patented technology, the net structure of the Abranet abrasive ensures a sanding particle is never more than 0.5 millimetres from a dust extraction hole. This means that sanding grains are able to retain their cutting power and the resulting dust is safely removed.

Abranet is highly resistant to dust pills and clogging, and is easily cleared to ensure optimal use out of every abrasive. With every coarseness grade providing excellent results, the original Abranet and its many versions are best combined with Mirka’s efficient and ergonomic power tools and dust extractors. New versions of the Abranet continue to be developed and patented.

“The Mirka Abranet net abrasive is a product of true Finnish ingenuity and ability to think outside the box. What started out as a laboratory experiment quickly proved its worth, and it’s a perfect example of the Mirka way of doing things,” says Hans Hede, Development Engineer and one of the ‘fathers’ of Abranet.

20 years later, dust-free sanding is widely accepted as an industry standard, with many competitors having seen the advantages of the Abranet approach. Original Mirka Abranet abrasives and their patented technology come from the Mirka factory in Jeppo, Finland, where it all started.