Knowing precisely when to replace the filter element in a truck’s fuel filter water separator (FFWS) can be challenging. Derek Martin, Engine & Mobile Filtration Division Europe at Parker Hannifin, explains the process.

Fuel contamination, either in the form of dirt or water, will find its way into fuel systems no matter how much care is taken to avoid it. With engines now injecting fuel at up to 2500 bar, and injector tolerances being measured in microns, it is hardly surprising that even a small amount of dirt or water corrosion can create problems. It only takes a tiny particle to block a passageway or prevent an injector from seating correctly.

Similarly, water in fuel can result in reduced lubricity leading to excessive wear. This loss of protection results in surface pitting and eventual pressure loss. Water in fuel can also promote undesirable microbiological growth. Ultimately, regular changing of filter elements over the lifetime of an engine can save thousands in engine refits, let alone downtime. The question is: when to do it?

Fortunately, there are many accessory devices available to remove the guesswork and ensure optimum filter replacement strategies. The only dilemma is deciding which device to deploy.

Vacuum restriction indicator

One such device is a vacuum restriction indicator, which monitors element condition as the filter slowly becomes blocked with contaminants. The upshot is increased flow restriction leading to a reduction in fuel delivered to the engine, causing it to lose power and eventually stall. By introducing a vacuum indicator in the fuel system, visual monitoring of the element condition is possible at a glance, increasing fuel system troubleshooting efficiency, and lengthening element change intervals.

Filter minder

Another useful accessory is the filter minder, a self-latching device that maintains its set condition even after the engine has been switched off. As soon as the filter element has been replaced, a filter minder can be reset simply by depressing the button on top of the indicator.

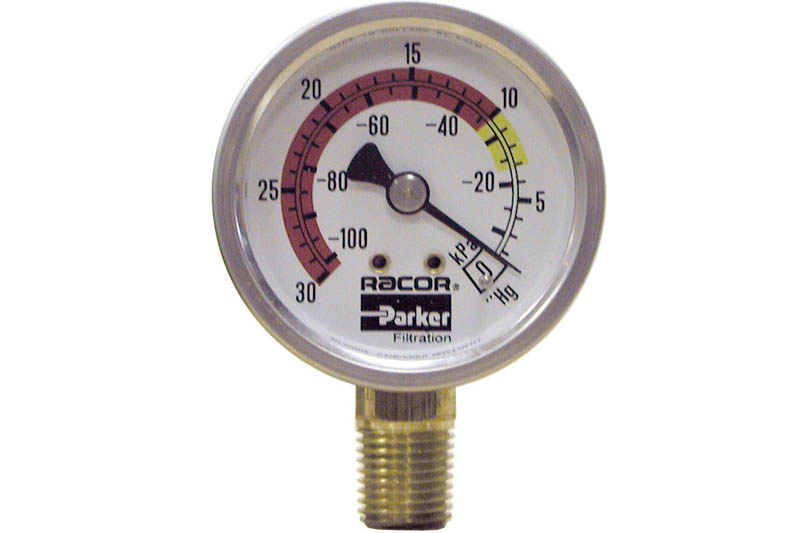

Vacuum gauge

For applications where a vent port is not available, a high quality vacuum gauge should be installed in the fuel delivery system at the outlet side of the FFWS to allow instant visual monitoring of the element condition. At the first indication of decreased performance, note the dial reading or apply the ‘red line’ decal provided with most kits. This will assist in knowing when to change the filter at the next interval.

Water detection modules

Water detection modules are also worthy of investigation – each is designed to suit particular FFWS units and installation requirements. These devices use an electronic detection module to analyse electrical resistance at a water probe fitted in the bowl of the FFWS. This determines if water is present, signalling that it is time to drain the FFWS. In addition to alerting the operator that water has collected in the bowl, detection modules can also indicate that the element restriction has reached a point at which fuel starvation may occur, meaning it is time to change the filter element.

Best practice

Ultimately, there is no better way to ensure engine reliability than knowing exactly when to change the element in FFWS units. If unsure which option is the best, then always seek advice from someone you trust. A supplier such as Parker Racor has decades of experience gained through the development of filtration media, such as Aquabloc3D, which helps it to recommend the best solution for a given application.

Whichever solution is selected, users should always ensure that any device claiming to determine the optimum replacement time for FFWS elements is validated for integrity, EMC compatibility, and safety. It should also be noted that, despite the advanced functionality of the latest devices for indicating filter element replacement, none are intended to supersede the condition-based service advice and schedules specified by the OEM vehicle manufacturer.