ZF Aftermarket details the recommended maintenance operations to ensure trouble-free bus front axle operation.

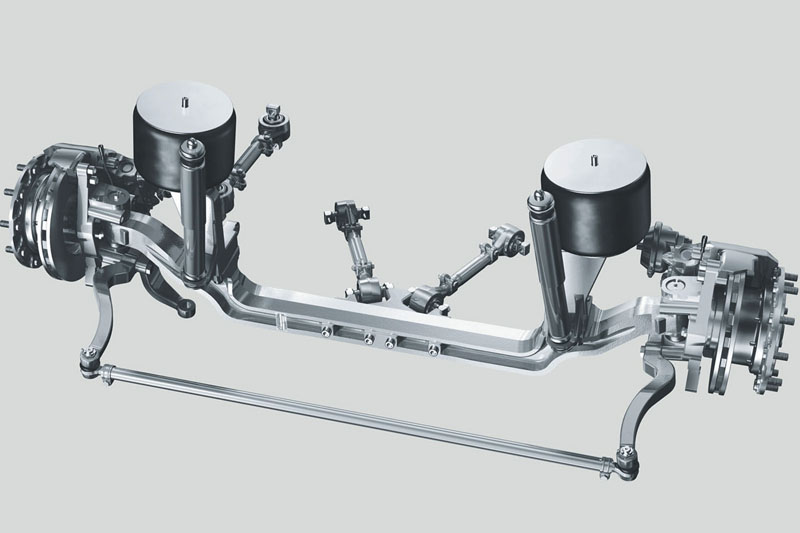

ZF RL-75A and RL-85A series front axles are a popular fitment on many manufacturers’ buses, as the design of the axle beam offers the ideal combination of a wide aisle between the front wheel arches, and a low floor height for easy passenger access. During production, the axle’s king pin inclination and castor angle are precisely engineered according to the original design calculations for optimum steering behaviour. To maintain this precision during the axle’s working life, the upper and lower king pin axial bearings must be lubricated regularly to prevent abnormal wear and avoid the need for extensive and costly remedial work resulting from bearing failure. Here, ZF sets out further maintenance advice.

Maintenance intervals

Lubrication should be carried out according to the vehicle manufacturer’s specified maintenance schedule. Where no specific information is available, ZF recommends attention to the bearings at least every 50,000 to 55,000 miles (80,000 to 90,000km) or annually, whichever occurs sooner.

Lubricant grade

Use a lithium-based, multipurpose grease meeting NLGI Class 2 (type KP2K-30 to DIN 51825). To select the correct grade, refer to ZF List of Lubricants TE-ML 12 (axles and wheel heads for buses and trucks) which can be found here.

This list is regularly updated with the latest recommended products.

Preparation

If the vehicle has been raised for other maintenance operations, lower it until the full weight of the vehicle is on the wheels. ZF RL 75A and RL 85A series steering axles must always be lubricated in this position, as it is the only way to ensure correct grease flow through the king pin axial bearings.

Procedure

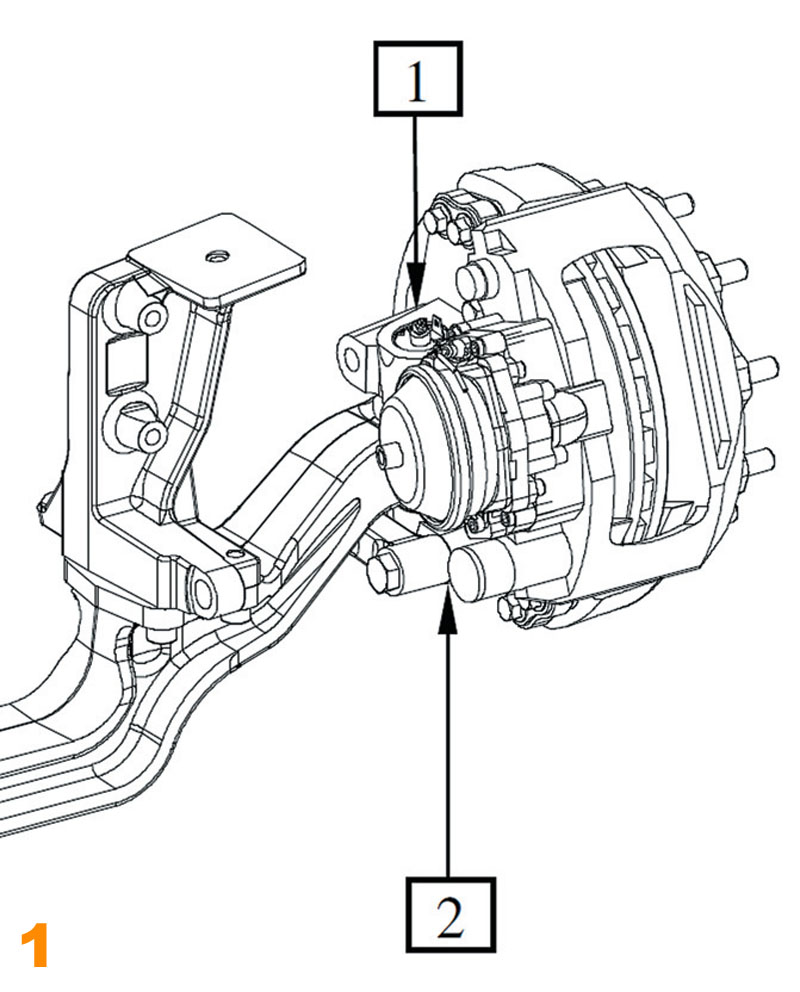

Locate the greasing points on the king pin axial bearings – there is an upper and a lower point on each hub (Figure 1). ZF recommends a conventional grease gun for this operation to avoid cracking the grease caps, although ZF field service engineers report that pneumatic greasing with air pressure limited to 6bars maximum has not presented any problems.

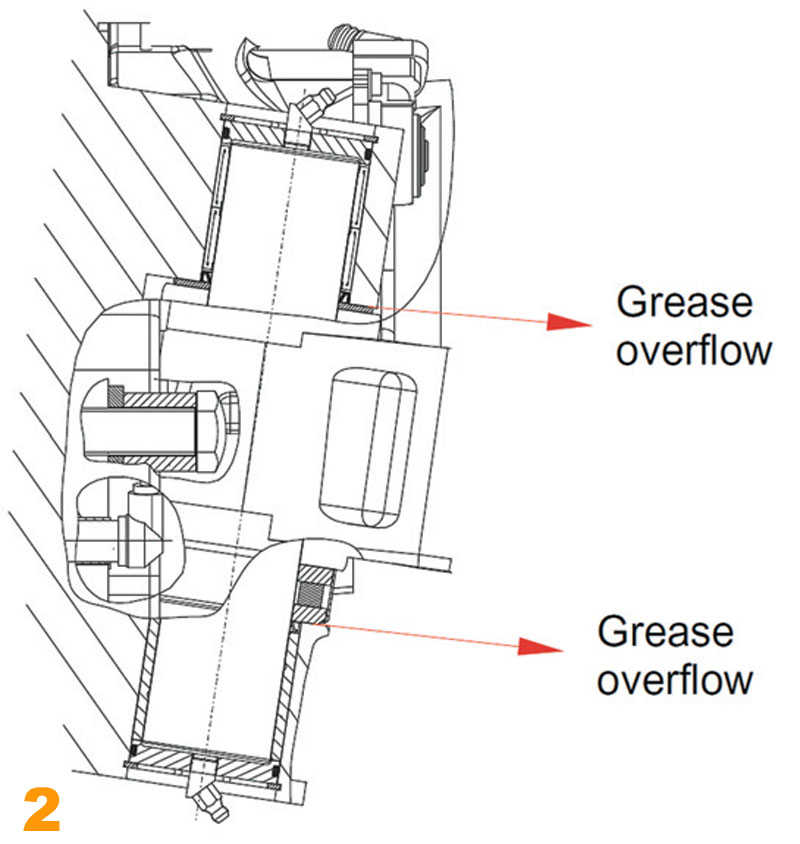

Using the grease nipple at the top bearing point, inject lubricant until fresh grease is seen overflowing from the seal rings of the upper axial bearing (Figure 2). Then, apply the grease gun to the nipple at the lower bearing point and inject until fresh grease emerges from the bottom of the lower axial bearing. Repeat this procedure at the upper and lower king pin axial bearings of the other wheel hub.

When lubrication has been carried out on both sides of the axle, turn the steering to full lock in each direction to assist complete grease penetration of both king pin axial bearings. Finally, repeat the entire lubrication process on the upper and lower king pin axial bearings on both sides of the axle.

Central lubrication systems

Where a central lubricating nipple or other central lubricating system is fitted, it should not be assumed that it will successfully provide all bearing points with a sufficient quantity of fresh grease. It is important to visually inspect the upper axial bearing seal rings and the bottom of the lower axial bearings as described above, to check that fresh grease can be seen exiting these areas after lubrication.

Precautions during cleaning operations

When pressure washing a vehicle, e.g. prior to annual inspection, avoid directing water at the king pin area. This will ensure that grease is not washed away, nor water forced into the bearings where it could cause corrosion of the king pin.

Consequences of neglected maintenance

Failure to adhere to the specified maintenance intervals and procedures can cause a number of problems. Where greasing intervals have been missed, the grease in the bearings may harden, making subsequent lubrication difficult or impossible. Another possibility is that lack of grease allows road water to enter the assembly and corrode the king pin.

In either situation, the problem must be referred to a suitably trained and equipped ZF technician for stripping and rebuilding of the king pin bearings, a complex process. The entire wheel assembly is dismantled using specialist tooling, then new components are fitted, including the king pins and their axial bearings. In cases of extreme wear, the stub axle casting may also need replacing. The reassembly procedure is not straightforward, involving controlled heating of the stub axle casting and simultaneous cooling of the king pin.

However, the need for a costly rebuild should be entirely avoidable, provided the simple lubrication procedures described here are carried out on schedule with thorough attention to detail, and the advised precautions noted.