Know your tristop cylinders from your combination brake cylinders? The ins and outs of double diaphragm brakes are explained by febi.

It comes as no surprise that heavy commercial vehicles require a particularly powerful braking system. Nearly all vehicles with a gross vehicle weight of more than 7.5 tonnes are equipped with a compressed air brake system.

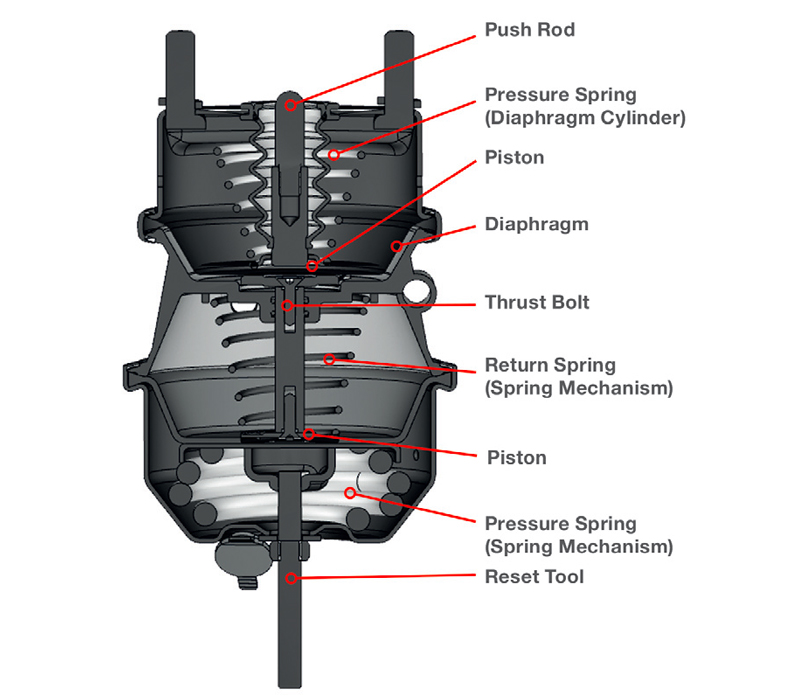

Brake cylinders are required to convert the energy contained in the compressed air into mechanical force. This takes place with the aid of a diaphragm, which is located in the housing of the brake cylinder. When the driver presses the brake pedal, compressed air flows into the brake cylinders. The diaphragm moves a piston and a pressure rod which transmit the force to the wheel brake.

There is a distinction made between brake cylinders with one and with two diaphragms. Brake cylinders with one diaphragm are generally used on non-driven axles. Brake cylinders with two diaphragms, also called double diaphragm cylinders, combination brake cylinders, or tristop cylinders, are installed on driven axles.

Double diaphragm cylinders consist of a combination of a diaphragm brake cylinder and a spring mechanism part. In addition to their function as normal driving brakes, they also serve as parking brakes and as auxiliary brakes. The diaphragm brake cylinder acts as a driving brake, the spring-loaded part as a parking brake.

In contrast to the driving brake, which is pressurised for braking, the double diaphragm cylinder also brakes when no compressed air is applied. A spring in the spring mechanism part actuates the brake until compressed air reaches the spring mechanism of the brake cylinder. Only then is the spring compressed by the diaphragm and the brake released.

No air apparent

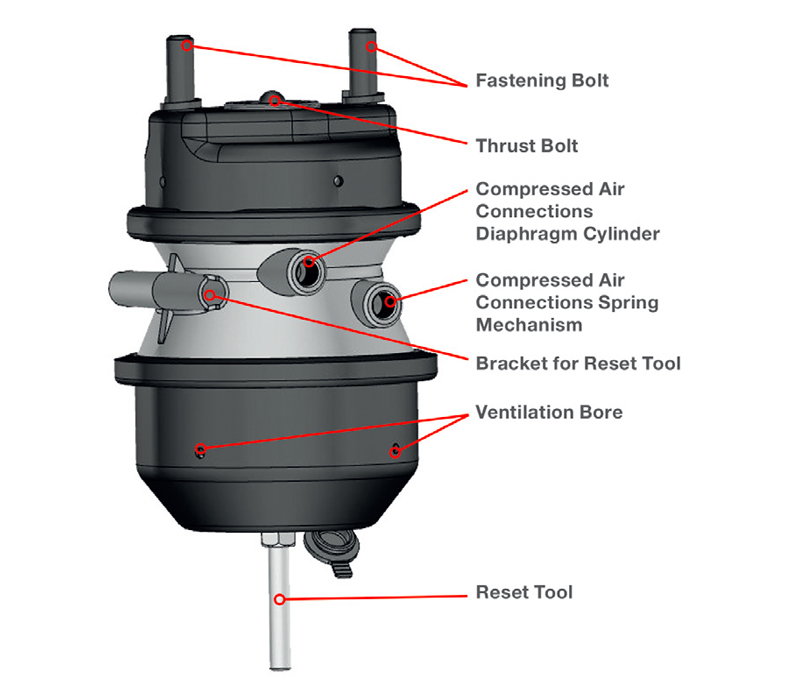

If the vehicle has no compressed air available, for example, due to a defect in the engine or the compressed air system, it is first braked by the spring in the spring mechanism. However, this spring can be retracted or tensioned with a reset tool which is inserted at the rear of the brake cylinder. Only then is the braking effect of the spring mechanism released.

A great danger is posed by the enormous force of the spring mechanism. If the clamp of the spring mechanism part is loosened, and the spring is not tensioned with the reset tool, then there’s the risk of personal injury. And don’t forget to remove the reset tool after use!

There are several reasons why the brake unit might fail, from corrosion of the sheet metal parts, leaks, the spring fracturing to even a torn diaphragm.

Not only should the brake cylinder be checked regularly for secure fastening, function, and wear, but also the mounting and surrounding components. If there is any doubt about the correct function of brake cylinders, they should be replaced.

The vents must always be free and must point downwards. If this is not the case, water and dirt can collect inside the brake cylinder and lead to corrosion.