First Line discusses the importance of water pumps, their vital role in allowing engines to reach maximum performance, and the correct installation procedure.

If the engine in any vehicle overheats, the damage can be severe and the cost to repair that damage extremely high. It is therefore always essential to have a think about the causes of some of the problems that are related to the installation of water pumps and the consequences of not following best practice and the manufacturers installation guidelines. The water pump is a major component on every vehicle, and performs the vital role of circulating coolant around the cooling system to ensure the engine doesn’t overheat.

Installation guide

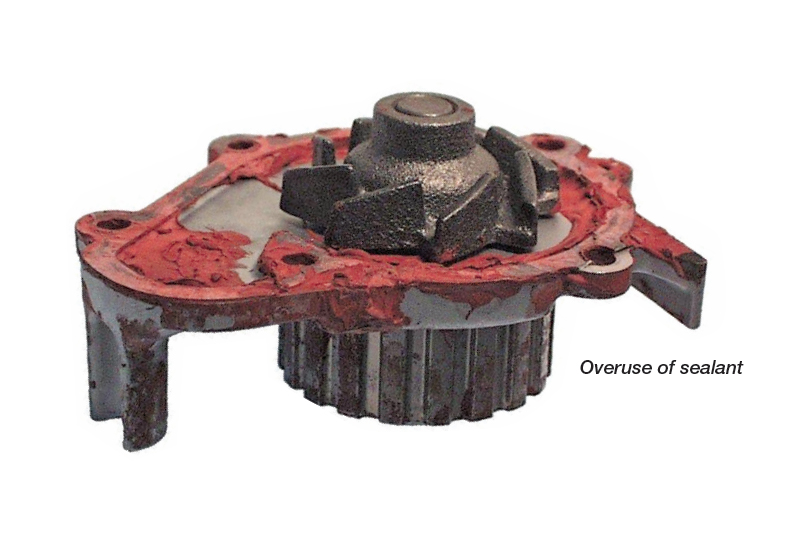

Only use a small amount of silicone RTV when installing ‘Face fit’ Water Pumps. Using too much sealant may cause it to be squeezed out of the facing when the pump is installed. As a result, contamination in the dynamic seal pack or another part of the cooling system is likely, which can lead to pump leaks, overheating and premature failure. Where a water pump is supplied with a gasket by the OE dealers, First Line follows and the gasket material is the same specification.

Always flush and clean the system before installing a new water pump to remove contaminates. Ensure that the correct specification and mix of new antifreeze and distilled water is used and that the whole procedure is in accordance with the manufacturer’s guidelines and intervals, especially when it comes to the correct bleeding process. Remember: Do not mix different types of Coolant.

If the levels of corrosion inhibitors are too low because of insufficient antifreeze, a build-up of rust, lime scale or impurities may get into the dynamic seal pack. This compromises the surfaces, which causes the water pump to leak and fail.

Finally, always check for incorrect drive belt tension or drive mis-alignment as well as an unbalanced or defective viscous coupling. The correct operation of coolant flanges, switches/sensors and radiator caps should also be checked.

Check the whole system for leaks. A small amount of coolant may be emitted from the pump body vent hole during initial running, but this is perfectly normal and may be present during the ‘bedding-in’ of the ceramic and carbon seal faces inside the dynamic seal pack.

Fitting a premium quality part initially, and by following the above advice, you will significantly reduce the amount of problems associated with carrying out cooling system repairs and maintenance, which not only saves a technician’s time, but can also ensure the customer’s satisfaction and therefore, returned business.

First Line offers a comprehensive range of premium quality water pumps and with more than 800 references available, every pump is manufactured to meet or exceed Original Equipment quality specifications. To ensure a total commitment towards optimum performance, quality and safety all First Line Water Pumps are manufactured by carefully selected global partners at ISO accredited.