Induction heating is a revolutionary way of heating metals and it is changing the way CV workshops operate! So says Neil Pulsford, managing director, GYS UK.

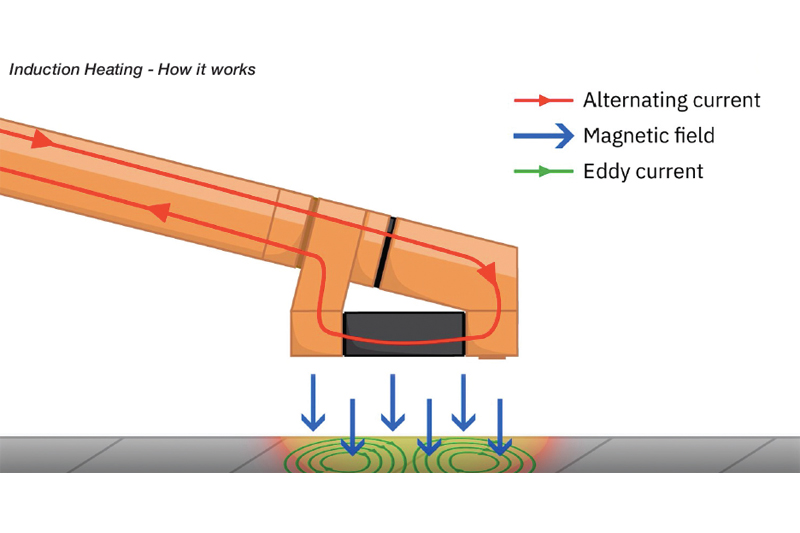

So what is induction heating? Well, it’s the process of heating metal by electromagnets. It works by an electronic device passing a high-frequency alternating current through the electromagnet. The rapidly alternating field penetrates the metal element, generating electric currents inside it – these are known as eddy currents – and they flow through the resistance of the material and heat it up. The induction heating process generates the heat inside the metal part rather than heating it by an external source, such as oxyacetylene.

Induction heating is extremely safe to use as there is no naked flame, so it reduces the risk of fire, allowing users to work near heat-sensitive or flammable areas without causing damage. It is also very accurate as it only heats the required parts, not the surrounding area, so targeting a localized area becomes very simple. It also heats to the heart of the metal in seconds, so is a lot faster than a flame. Very little training is required as it is so easy to use. In addition to the above, the real benefit to workshops is financial, as it could save them up to 30% on their insurance premiums, and work out 90% cheaper to run than oxyacetylene.

Versatile process

Oxyacetylene is dangerous as it uses a naked flame and explosive gases. It is also imprecise so there is greater risk of damage to fuel pipes, wiring looms, rubber components, sensors and AdBlue tanks. It represents a health and safety risk and is a danger to members of staff, customers’ vehicles and premises. It is also expensive with cylinder rental costs and gas purchases. The gas cylinders are difficult to store and they also increase insurance premiums.

Induction heating is a versatile heating process providing instant and powerful heat to release or separate dissimilar metals or preheat steel or aluminium for a range of purposes: seized wheel nuts, brake bleed nipples, exhaust manifold bolts, brake discs, brake hoses, exhaust flanges, exhaust pipes, shock absorber nuts, loosening bolts, removal of steel or aluminium parts and straightening bent frames to name a few.

Workshop customers who have gone down the induction route are experiencing great results. Take Rydam Universal for example, sole UK service partner for Faymonville, Specialist Trailers of Belgium. The company recently bought two GYS Powerduction 220LG induction heaters. With a maximum heating power of 22kW, the 220LG can heat up steel or aluminum in a few seconds, without flame and with pinpoint accuracy.

According to Adam Green, Rydam’s engineering director, the induction heaters have become an integral part of the workshop kit, bringing safety and efficiency to the fore. An operator can now work on their own rather than having two people, one using the flame torch and oxyacetylene gas and another one removing the parts. As some Faymonville trailers are very complex with electronics, sensors, steering systems, hydraulic pipes, etc, they require engineers to be extremely careful when working on them. Removing hydraulic cylinder pins inside the superstructure, amongst all the pipes and wires is an ideal job for the induction heater. Heat can be applied to the collars and bushes without warming the actual pin as with flame equipment, so removal is far easier and much more precise, avoiding damage to the surrounding pipes, wires, sensors, etc.

Induction heating is also used extensively on chassis damage, straightening panels, and side frames on accident-damaged trailers, saving time and further remedial work associated with conventional flame equipment.

What’s more Adam is really sold on the advantages of a “no flame” workplace, as it means that it satisfies the company’s insurance requirements for H&S compliance and creates a safer working environment.