HELLA unveils its expanded offering

Responding to calls from commercial vehicle (CV) workshops for OE quality 24V NOx sensors, HELLA has significantly expanded its offering. Here it tells CVW what’s new.

HELLA’s NOx sensor range now has more than 80% coverage on Europe’s most popular vehicles, including DAF, Mercedes-Benz, MAN, Scania, Volvo, Renault and Iveco applications. It forms part of a wider investment in CV electronic components, as the OE supplier meets aftermarket demand for hassle-free replacements.

“NOx sensors are subject to extremely harsh conditions,” says Matthew Smart, HELLA’s head of electronics. “That’s why we’ve given particular attention to ensure our NOx sensors are resistant to CV engine vibrations and high operating temperatures.”

Warning signs

Standard on all commercial vehicles from Euro 5 onwards, NOx sensors measure nitrogen oxides in the flow of exhaust gas as part of the urea-based selective catalytic reduction (SCR) treatment. The NOx sensor guarantees an optimal dosage of AdBlue, bringing an effective reduction of nitrogen oxides.

“Common causes of failure tend to include a build-up of soot on the sensor probe, water intrusion into the ECU and damage to the cable, all of which will result in an illuminated engine management light,” Smart continues.

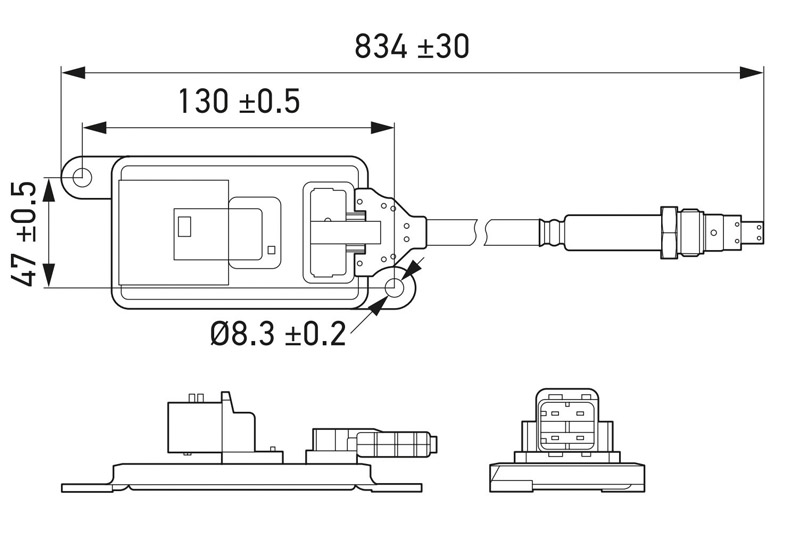

The NOx sensor comprises a probe housed inside the exhaust system, and a control unit. Some SCR systems feature an upstream and a downstream NOx sensor, with the downstream sensor tasked with monitoring the effect of the SCR catalytic converter. Exhaust gas enters the diesel oxidation catalytic converter (DOC), where carbon monoxide (CO), hydrocarbons (HC) and particulate matter (PM) emissions are first reduced before the flow of gas continues into the diesel particulate filter (DPF).

The DPF further captures and removes harmful particulate matter from exhaust gases. The accumulated soot is then periodically burned-off through a ‘regeneration’ process, normally either ‘passive DPF regeneration’ or ‘active DPF regeneration’.

On vehicles with an SCR system, the gas flow then faces treatment to reduce the amount of nitrogen oxide. AdBlue is added to the gas, causing a reaction which converts nitrogen oxides (NOx) into nitrogen (N2) and water (H2O).

Finally, where an ammonia slip catalyst (ASC) is fitted, excess ammoniac (NH3) is converted into nitrogen (N2) to further reduce NOx emissions. According to Smart, HELLA’s OE expertise is central to the development of its NOx sensors. He says: “These components are developed in compliance to OEM specification and tested in accordance with HELLA quality standard. They’re quite simply a like-for-like OE replacement.”

Demand for OE-quality NOx sensors is expected to grow as vehicle manufacturers continue to reduce harmful emissions, complying to ever-tougher limits. The current Euro 6 standard introduced in 2015, for example, imposed a 67% reduction in diesel NOx emissions compared to Euro 5.