High-quality seams are essential in bodywork repair. They need to withstand the harsh road and weather conditions and should also provide a good foundation for a quality paint finish that complements brand aesthetics. In short it needs to be as close to OEM-standard as possible. Henkel explains.

There are now various adhesive products and single system solutions on the market, able to recreate sealing seams that match OEM specification in every regard, whatever type of finish is required. Indeed, many of them are actually OEM approved having been developed in close partnership with OEMs in vehicle manufacture and the aftermarket.

So, as a body shop serving the commercial vehicle sector, what do you need to know to make an effective product choice?

Several properties need to be considered. The seal should exhibit an adhesion spectrum that extends to a wide range of materials and also demonstrate high stability, that is, retain its shape after curing. Elasticity to accommodate movement in the chassis without cracking is another important factor. Also look for products that are easy to smooth in the event of imperfections during application.

Do you need to overpaint the seal? Or is yours an unpainted application, requiring UV resistance, or a bare metal application where long term corrosion protection is essential. And what about tolerance to spot-welding? Sealants are available that tick all these boxes, either individually or within a single seam solution that covers all applications.

Also check if the sealant is free from silicone and isocyanate. This is particularly important in light of an EU regulation. EU 2020/1149 sets out that contact with isocyanate, both by skin and inhalation, is undesirable due to health concerns. Indeed, the regulation specifies that chemical-based products should now contain less than 0.1% of isocyanate by weight.

Employers must also ensure that users have successfully completed training in the safe use of isocyanates. The upshot of this development is that using sealants containing isocyanate now introduces extra time and costs for body shops.

Low shrinkage is another prerequisite for producing sealing seams in vehicle bodies. Chemical curing – as opposed to physical curing – offers extremely low-shrinkage characteristics. Two popular chemical curing technologies are available in this category, one based on polyurethane (PUR) and the other on silane modified polymer (SMP). SMP does not contain isocyanate, making it the optimum choice.

A good example of an SMP-based chemical-curing sealant is TEROSON MS 9320 SF from Henkel. Available in different colour choices, this product can receive paint just 30 minutes after application. TEROSON MS 9320 SF offers good stability, is free of isocyanate and silicone, and provides impressive adhesion to many different surfaces without primer. The product also gives good resistance to UV.

Another important attribute of the latest sealing technology is corrosion protection. In the case of TEROSON MS 9320 SF, it is 100% water resistant and covers any rust, stopping it in its tracks. Indeed, it is now an OEM-approved and a recommended treatment for aftermarket corrosion protection.

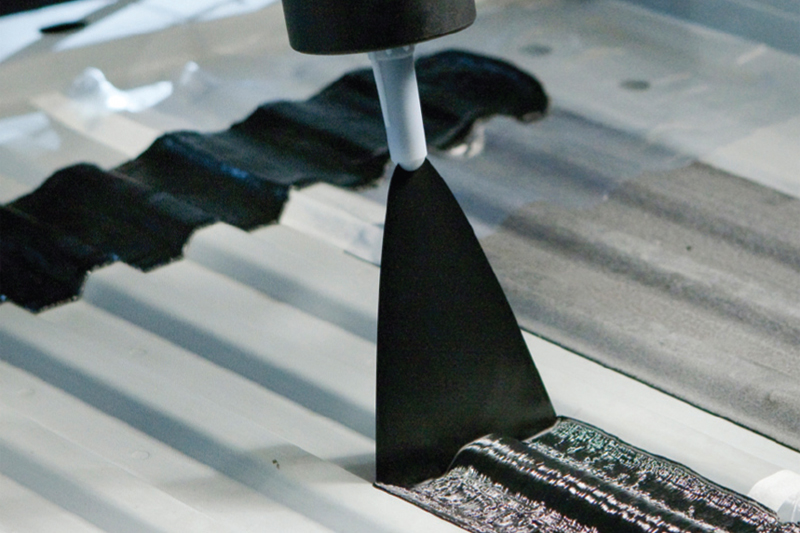

Alongside performance attributes, appearance can also be important for some seam sealing applications. Surface structure is a critical factor here, which is why the latest innovations in seam sealing technology can replicate different textures: smooth, via extrusion in a constant material flow; rough/wavy, using spray technology; and fine-ribbed/rippled, by high-pressure spray.

For each surface structure, choosing the correct application nozzle and tool form a critical part of successful bead creation. From standard, double-head, universal and butterfly nozzles, through to flat-stream and wide-stream nozzles, there is a solution whatever the task in hand, be it side panels, doors, lift gates or bonnets.

Teroson webinar

Click here to register now for Teroson’s 40-minute webinar on Thursday 10th November and learn how to recreate all original OEM seams. Two experts in collision repair will explain the seam sealing technology and its interior and exterior applications. You’ll also be given a grounding in the different adhesives available and their respective properties.