How can you simplify brake testing compliance?

The DVSA’s 2025 updates to HGV brake testing requirements introduce new challenges, but Stuart Window, general manager at Bowmonk, believes it is a chance for workshops to adopt the tools and processes that can simplify compliance.

More expense, more aggravation, and more visits to the test station – that seems to be the general reaction among fleet owners and operators regarding the upcoming mandatory brake tests. There’s a persistent misconception that these additional tests must be carried out at an Authorised Test Facility (ATF) yet this need not be the case. The Driver and Vehicle Standards Agency (DVSA) allows operators to perform their own brake tests using a DVSA-approved portable meter.

The recent 2025 updates to the Guide to Maintaining Roadworthiness bring crucial new steps to HGV brake testing that will impact operators and workshops across the UK. As general manager of Bowmonk, I’ve observed first-hand how these changes are causing concern in the industry. But, with the right approach and equipment, compliance can be straightforward and even beneficial to operations.

The DVSA’s updated guidelines highlight the continued use of decelerometers for testing overall brake efficiency, especially in cases where a roller brake tester (RBT) may not be suitable. But the guide now emphasises that decelerometer tests must include pre- and post-test brake disc temperature checks. These temperature readings confirm that each brake on an axle is functioning correctly – something a decelerometer alone cannot verify.

To meet this requirement, workshops must use an infrared temperature gun to record brake temperatures at the beginning and end of the test. The DVSA specifies that final temperature readings should show a significant increase compared to initial readings, with consistent temperatures across all brakes on an axle. If these criteria aren’t met, additional testing methods may be necessary to confirm brake functionality.

Added flexibility

I believe this additional step is a positive move towards enhancing road safety. While decelerometer testing has always been a reliable method for assessing overall brake efficiency, incorporating temperature checks provides a more comprehensive evaluation of each individual brake’s performance. It ensures that every component is contributing to the vehicle’s braking capabilities as expected.

There’s a significant advantage in being able to conduct these tests without the need to visit an ATF. Utilising a portable, DVSA-approved device allows operators to perform brake tests at any time and location. This flexibility minimises downtime for fleets, eliminating the need to leave vehicles at a test station and incur a full day of revenue loss. In my experience, the investment in portable testing equipment quickly pays for itself after just a few tests. It empowers operators to take control of their compliance processes, ensuring that vehicles are roadworthy without the logistical challenges of scheduling and traveling to an ATF.

Record keeping

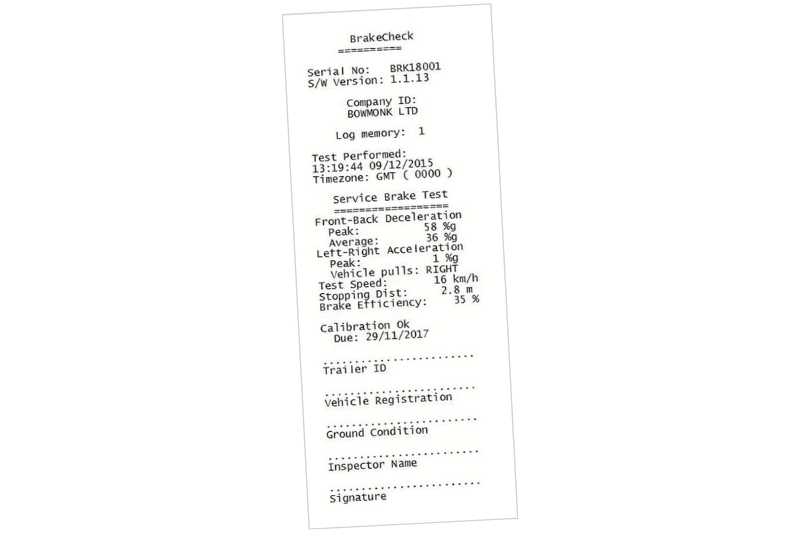

Another critical aspect of the updated guidelines is the emphasis on thorough record-keeping. Workshops and operators must maintain detailed documentation of brake tests, including efficiency readings and temperature measurements. These records are essential not only for compliance but also for audits and inspections. Digital solutions can greatly simplify this process, enabling quick access and review of records while enhancing their accuracy. I know that many workshops and operators are concerned about the additional steps these new requirements introduce. However, with the right tools, these steps can be seamlessly integrated into existing processes. Our BrakeCheck kit, for example, combines a DVSA-approved decelerometer with an infrared temperature gun, allowing workshops to carry out comprehensive, compliant brake tests with minimal disruption.

The kit also includes a wireless printer for instant, DVSA-compliant test reports, and an optional PC software package for digital record-keeping. This software enables workshops to store, review, and manage brake test data, including temperature readings and efficiency results, ensuring that documentation is both thorough and easily accessible. These features make compliance not just achievable but efficient and stress-free for operators and workshops alike.

The DVSA’s new section 5.3a, Braking Performance Assessment, effective from April 2025, requires all safety inspections to include brake performance assessments. These assessments should be performed using an RBT, an electronic brake performance monitoring system (EBPMS), or a decelerometer with temperature readings.

I see this as an opportunity for the industry to enhance its commitment to safety. By adopting these comprehensive testing methods, operators not only comply with regulations but also contribute to safer roads for everyone. The updates are about more than ticking regulatory boxes – they’re about making our roads safer and ensuring every brake is functioning as intended.

Commitment to safety

The updates to the DVSA’s guidelines may initially seem daunting, but they represent a significant step forward in vehicle safety standards. By understanding the new requirements and adopting suitable testing methods, operators can ensure compliance without unnecessary disruption to their operations. Performing brake tests with a portable, approved device, along with the necessary temperature checks, provides a practical solution. It reduces downtime, eliminates the need for frequent visits to an ATF, and enhances the overall safety of the fleet.

As we move towards the April 2025 deadline, I encourage all operators and workshops to familiarise themselves with the new guidelines and consider how best to integrate these practices into their maintenance routines. Embracing these changes proactively will not only ensure compliance but also demonstrate a commitment to safety and excellence in the industry.

![Bosch outlines ESI[tronic] workshop software](https://cvwmagazine.co.uk/wp-content/uploads/2025/07/Bosch-ESItronic-25-165x109.jpg)