How could AI revolutionise fleet maintenance?

Fleet maintenance is on the cusp of an Artificial Intelligence (AI) revolution. But without a strong digital foundation, the benefits could remain out of reach, warns Patrick Tandy, managing director at Freeway Fleet Systems.

Artificial Intelligence is about to start a step-change in fleet maintenance, providing operators with greater control over all the many elements than ever before to create leaner, ever more efficient and economical logistics. But tapping into AI’s full potential requires more than just plugging it in. To get it right, fleet operators need a solid digital foundation, structured data, and strong leadership to steer the ship.

Before AI can deliver its benefits, your fleet operations must be fully digital. Paper-based systems or even computerised setups that just mimic paper processes won’t cut it. AI needs real-time, accurate data to work properly. Without it, the insights you want – such as predicting maintenance needs or cutting costs – won’t happen.

A common mistake that many companies make is simply transferring their old processes onto a computer. This misses the point of going digital. Instead of entering data at the end of a shift, a true digital system lets your team input and access information as it happens. Whether it’s reporting a vehicle defect or updating maintenance schedules, this live data becomes the backbone of your AI-powered system.

AI works best when it has structured data. For example, instead of a driver typing in “mirror broken” as free text, a digital system would let them pick from predefined options like “bent wing mirror arm.” This structured data is easier for AI to analyse, leading to better predictions and faster decision-making. It also speeds up the reporting process and links directly to known repair times and parts needed – saving time and money for your operation.

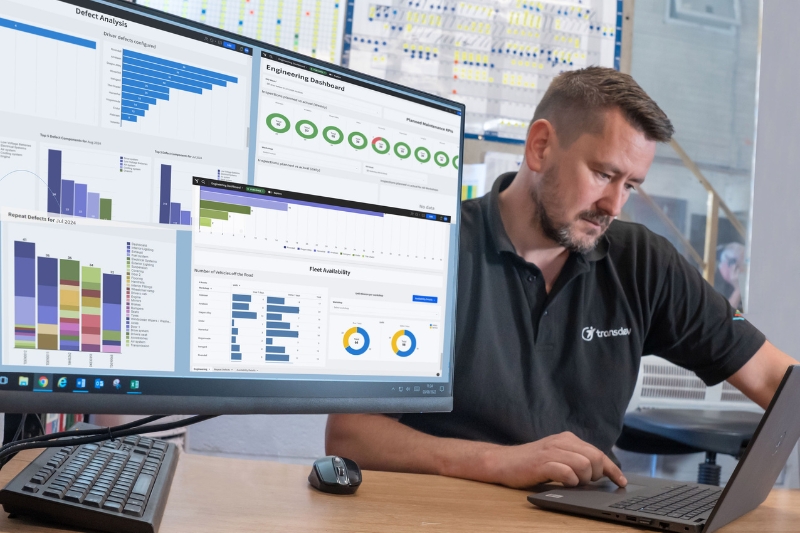

A digital fleet management platform should cover everything, from tracking assets and reporting defects to planning maintenance and controlling inventory. AI can then connect the dots, recognising patterns and offering suggestions based on the complete picture. If you’re missing key information – maintenance history, for example, or parts usage – AI’s recommendations won’t be as useful.

But AI isn’t a replacement for human expertise. It needs someone with experience to guide it. You need to know your goals before you can make the most of AI. For example, if your priority is keeping vehicle downtime to a minimum, AI can help. But you also need to balance that with the workload on your maintenance team, so they don’t burn out. Clear objectives ensure AI is giving you the right insights for your business.

As AI technology advances, it will open up even more opportunities – along with new challenges. Here are three key points to keep in mind: Future proofing, control and security.

Inevitably, AI will develop so the technology you implement today must adapt to future innovations. Ensure your system connects to cloud-based data tools, so when the next iterations of AI arrive you can adopt them without a major overhaul.

Stay in control of your data: AI may provide sophisticated results, but you should always be able to verify the logic behind its recommendations. Make sure your system allows you to review the data inputs, so you know exactly how AI is arriving at its conclusions.

Keep your data secure: ensure that your AI tools give you full control over how your data is stored and used. Choose systems that use secure methods, like API keys, so your data isn’t stored by third parties. This keeps your sensitive information safe.

In the end, AI is a powerful tool that, when combined with a digital fleet management system, can transform how you operate. But it’s not magic — it’s about working smarter. By building a strong digital foundation, using structured data, and staying in control of your insights, you can unlock the full potential of AI while future-proofing your fleet.