How to maintain auxiliary belts

The team at febi look at the make-up of an auxiliary belt and some problems, causes and solutions when it comes to maintaining them.

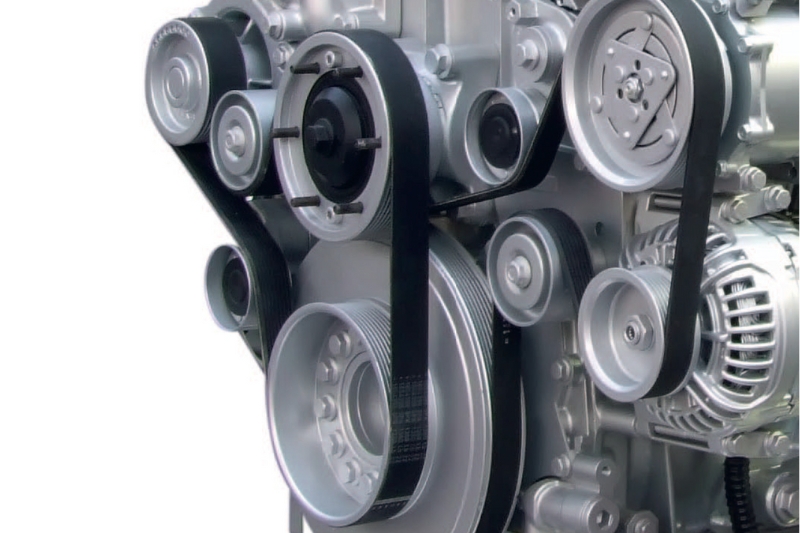

The auxiliary belt is responsible for driving auxiliary units such as the alternator, water pump, radiator fan, and air conditioning compressor. The belt is driven by the crankshaft pulley and transmits the engine’s power to the pulleys of the auxiliary units via the friction of the side ribbed flanks on the underside of the belt.

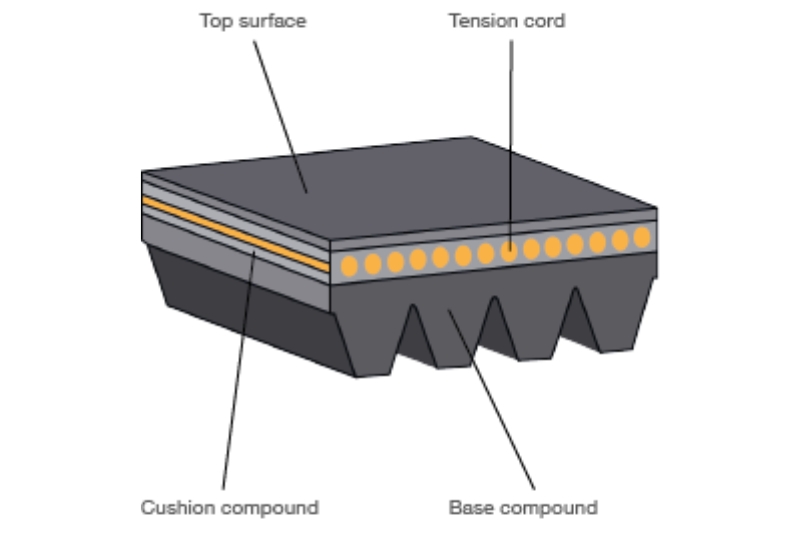

The top surface of a premium belt is made of durable EPDM – ethylene propylene diene monomer (M-class) rubber – a material extremely resistant to wear and temperatures ranging from -40°C to 130°C.

The tension cord layer made of polyester fabric achieves the high tensile strength and stability, which allows very high torque to be transmitted with minimal elongation over the belt’s complete lifespan. The cushion compound made of high-adhesive polychloroprene rubber embeds the polyester fabrics safely and reliably connects the EPDM top surface and the base compound.

The polychloroprene rubber base compound ensures that the belt can reliably withstand the forces generated by transferring large amounts of power while operating at high speeds. This state-of-the-art design and the use of high quality materials in construction means febi auxiliary belts are the embodiment of functionality, reliability, and longevity.

Time for a change?

Belt maintenance, both regular and preventative, is essential to ensure reliability. As its functional principle is based on friction, normal abrasion over time causes the auxiliary belt to become thinner.

The good news, however, is that auxiliary belts today are incredibly durable and very rarely break. How frequently one is replaced depends on several factors; including what the vehicle is used for, where it’s driven, how the belt is made, and the recommendations of the vehicle manufacturer. External influences such as environmental contamination or extreme temperatures also have a great influence on the longevity of the belt.

It is not just the belt that wears, other components such as the idler and tensioner pulleys and the belt tensioners are also subject to degradation over time. Typical failures include excessive play or rough running of the bearings. These components don’t have to be changed as often as the belt itself but should be checked every time a new one is installed to ensure the complete auxiliary belt drive system functions correctly.

To prevent unexpected and premature vehicle breakdowns, checking all auxiliary belt drive components every 60,000km or once a year, and to change all components as a preventive measure every 120,000km is recommended. Vehicles that operate in harsh conditions such as on a construction site should be serviced even earlier.

In addition to auxiliary belts, febi also offers many other aux belt drive components including tensioner assemblies, tensioner pulleys, and idler pulleys. To shorten the search for individual components and minimise the calculable downtime of vehicles, febi offers numerous complete Auxiliary Belt Kits which include all needed vehicle specific components.

Proper storage

The quality of a belt can be maintained for years if stored properly in a dry place between +15 to +25°C. Incorrect storage, e.g. exposure to oxygen, light, extreme temperatures, or moisture, can change belt’s physical properties and render it unusable.

The drive belts should remain in their original packaging and be stored without tension until they are used. When stacking, a height of 300mm should not be exceeded, otherwise deformation may occur.