IMS details a technical guide to keep the SAF Intra Suspension running smoothly and efficiently.

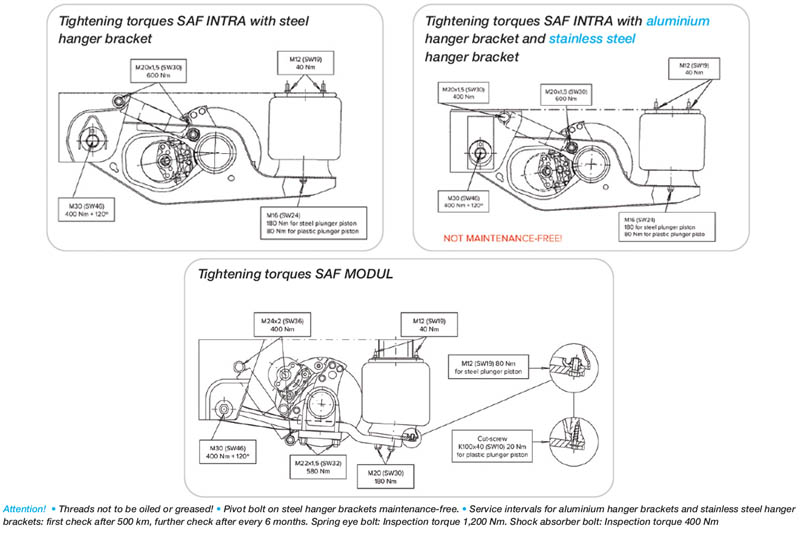

The pivot bolt is maintenance-free if used in combination with the steel hanger bracket. After the initial PDI, check on the torque and then again check every trailer in-service inspection. Stainless steel and aluminium hanger brackets are not maintenance-free. These pivot bolts should be checked after 500km and then every six months. The inspection torque is 1200Nm.

A loose pivot bolt can cause extreme damage to the 3D Bush and also the Hanger Bracket. This can be worn away beyond repair and the bracket will have to be changed. There is the facility to adjust the tracking with the tracking washers on the hanger bracket. This can be adjusted 12mm overall, 6mm forward, and 6mm backwards.

The 3D bush in the Intra suspension system has an elastic movement of +/- 14mm (a total, therefore, of 28mm). This elasticity does not cause any damage to the bush, it is essential for the proper function of the suspension system. The maximum values of +/- 14mm are only achieved during state testing and do not occur during trailer operation.

The form of the 3D bush means that it is significantly more rigid in the horizontal direction than in vertical direction so it is vital that the 3D bush is properly fitted as otherwise it will not operate properly. The bush must be fitted with the word top pointing upwards while the suspension is sitting in the running height position.

When replacing the pivot bushes it is recommended that the plastic wear washers are replaced at the same time. The washers are there to prevent metal to metal contact between the hanger bracket and the trailing intra arm. There is a SAF Bush replacement tool available which makes the whole process of bush replacement manageable. The part number of the tool is 34343326HE.

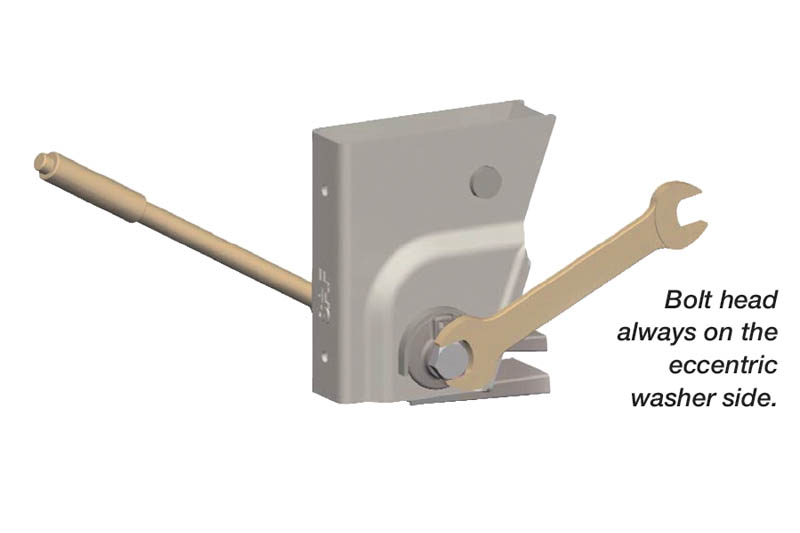

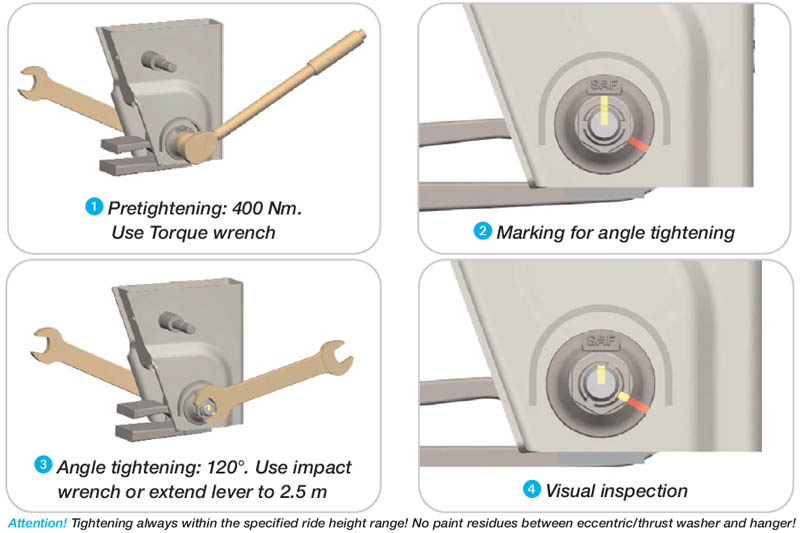

The pivot bolt is torqued to a setting of 400Nm with a further angle tightening of 120 degrees (two flats of the nuts). This should always be done with the trailer axles sitting at running height. If the pivot bolt is ever removed, it should be replaced with a new one. The pivot bolt must only be torqued while the trailer is sitting in the running height position otherwise the bush will turn when the trailer is sat back down on its wheels.

The SAF Intra shocker absorbers are patented due to the angle at which they work. They also have a small valve in the base which assists the shocker to work correctly at this angle. The shocker has the word top stamped on the body and must always be fixed with this facing upwards for the valve to work. There is also on-road and off-road shockers fitted depending on the application of the suspension, off-road shockers are always red in colour and should be replaced like for like.

Modular suspension is the more traditional suspension setup with springs, nuts and U-bolts. It has the same spring eye adjustment for the tracking but uses a metaplastic spring eye bush. Again, the pivot bolt torque is 400Nm plus the angle tightening of 120 degrees.

The Modular trailing arm is surrounded with a metal wrap to protect everything should the spring ever break. U-bolts must be torque to 580Nm and replaced every time they are removed.