IMS explains how trailer technology has advanced to become a key consideration for fleet operators.

The humble trailer is no longer the Cinderella of commercial vehicle transport equipment, according to trailer specialists at IMS. Trailer specification has often been a secondary consideration for transport operators involved in the vehicle acquisition decision-making process, with the main focus being on the high tech tractor units.

Trailer technology has come along in leaps and bounds in response to the transport industry’s need to squeeze every iota of efficiency from their fleets. The trailer is fast becoming more intelligent and therefore able to make a greater positive contribution to the cost-effectiveness of the semi-trailer combination. Far from being just a metal chassis with sundry components attached, now fleet operators want a sum of integrated parts that together offer meaningful benefits: weight optimisation, enhanced handling characteristics through steering technology, tyre pressure monitoring, powered and energy recovery axles, plus performance and maintenance data in real time.

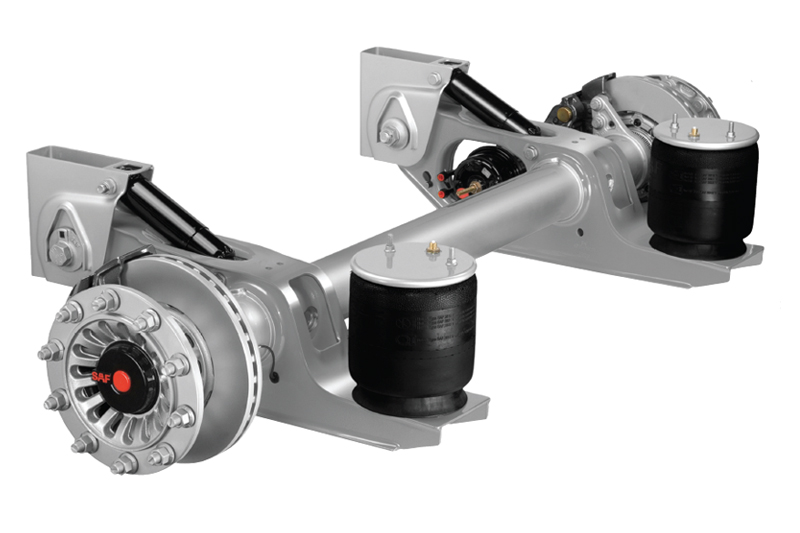

IMS, a new member of the SAF-HOLLAND Group, has long been aware that in delivery and distribution, every kilo counts which is why it has worked consistently on developing payload-optimised axles like the INTRADISC plus INTEGRAL. The company’s latest development of the ten-spoke wheel end design and weight-relieved brake caliper together reduce the weight by 24kg on a triaxle trailer, which is not insignificant. But importantly, none of this weight saving is made at the expense of performance or longevity. Canny operators are also seeing the benefits of fitting the SAF TIRE PILOT system to their SAF trailer axles. The system accurately monitors tyre pressure continuously and maintains minimum pressure in the event of puncture damage. The system aims to reduce tyre wear and save fuel. It also means that spare wheels need not be carried, providing a further weight saving and thereby increasing efficiency.

Low maintenance axles

Fleet operators necessarily spend a lot of their time managing the whole-life costs of their commercial vehicles and in this respect, SAF axle-equipped trailers generally acquit themselves extremely well. SAF axles are very low maintenance by design and come with some of the longest warranties in the industry. The new SAF INTRA PC (Premium Coated), developed for semi-trailers operating in the harshest weather conditions, comes with a 10-year anti-corrosion warranty on the additional coating.

The industry is now seeing technological developments that will both enhance vehicle efficiency and make life easier for transport operators. Trailer telematics allows fleet managers to keep tabs on performance and maintenance schedules in real time. Powered trailer axles are with us now and are making huge improvements to vehicle handling in difficult off-road driving conditions, and energy recovery systems for trailers are in production.