Juratek explains the different loads which brakes can be exposed to and how its offering attempts to cover all the bases required.

An old saying is that you only get out what you put in; in the computer world, they even have an acronym for it – GIGO. The same is true in the braking field; the performance and durability of the friction material (the output) is only as good as the input. Namely, the raw materials – the way they are blended together, the manufacturing process, and the quality control process that overlays the whole.

Commercial vehicles experience a wide spectrum of use in service, and this has a direct bearing on the duty to which their brake system is subjected and the operating temperatures that are reached. At the one end of the scale, vehicles can be running up and down the motorway hardly ever applying their brakes, others could be on delivery use involving constant stopping and starting, whilst others could be employed as tippers. Yet others can be on routes with long hill descents involving continuous application of the brakes.

Brake temperature mapping of these very different operating conditions indicates peak temperatures can typically range from the relatively modest 20°C under light conditions of use all the way up to 85°C during long hill descents.

Points to remember

The development of fully service-compatible brake pads and discs must recognise and cater for all of these possible conditions to ensure that the resulting products that are offered for sale are safe and durable. It is not enough to simply carry out the mandatory UNR90 tests which only cover the basic braking effectiveness and fade, and not the performance, durability, and compatibility between brake pad and brake disc under the wide range of different service operating conditions.

With its new Synergy premium brake pads, Juratek is employing the best raw materials, state-of-the-art production processes, and quality control to ensure it has excellent performance and durability across its full service temperature spectrum. This friction material has been developed to optimise the synergistic relationship between friction components and a vehicle’s performance and service life.

Safety first

Brake friction components are critical to safety. With heavy demands on performance, these components need to be robust and to work efficiently and effectively in all environments. Synergy braking has been proven on truck, trailer, bus, and coach applications to provide premium braking performance and durability under all service operating conditions. It is tested and approved by the VCA, the UK’s designated type approval authority with more than 30 years’ experience in testing and providing certification for vehicle systems and components.

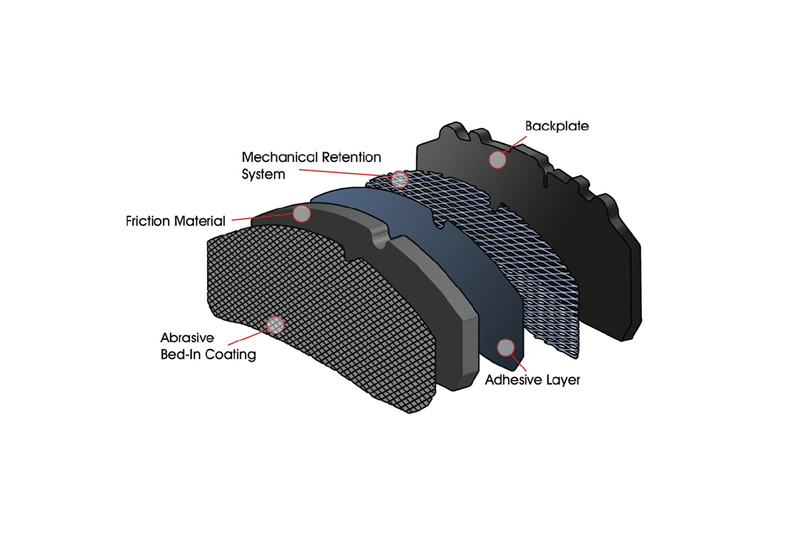

Synergy braking features meshed backplates to provide enhanced mechanical retention of the pad to the backplate, and high friction bedding coatings on the surface of the pad. These coatings help remove debris and contamination from the braking surface of the disc left behind by the former set of pads and provide more rapid bedding of the new set of pads to the disc when pads are replaced.