Under pressure to get vehicles out of the workshop and back on the road quickly? Specialist tools can save you time and money without compromising safety, says Knorr-Bremse.

Workshops often have to operate against the clock. At the same time, high levels of precision are essential for safe, clean, and reliable repair and maintenance operations. Some jobs are trickier than others and Knorr-Bremse has expanded its range of special and auxiliary tools to make those jobs that little bit easier.

The tools have been developed in co- operation with specialist tool manufacturer GEDORE. Some are designed to make it easier to correctly fit replacement parts; others are designed to save valuable workshop time by speeding up essential safety checks. There are complete kits and individual tools available.

Air disc brake tool kit

The tools for almost all current Knorr-Bremse brake types have been brought together in a single new tool kit. Everything you need to carry out professional maintenance is supplied in a compact box so that you can move seamlessly from one operation to the next without wasting valuable time.

Actuator maintenance gauge

The actuator maintenance gauge enables the height of the seal and push rod to be rapidly inspected, ensuring that orientation of the actuator corresponds exactly with the original installation. Furthermore, during maintenance with an original Knorr-Bremse actuator kit, or when fully replacing a spring brake with a rationalised unit, the gauge helps the operator to correctly re-assemble the components.

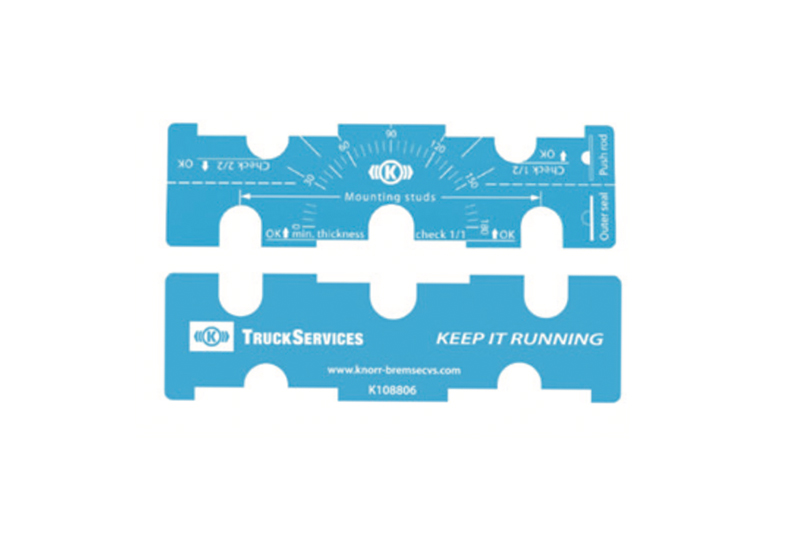

Brake disc measuring gauge

The brake disc measuring gauge enables technicians to check brake disc wear within a few seconds, without having to remove the wheel first. It works with 17.5, 19.5, and 22.5in brakes. As the wheel remains on the vehicle, downtime is reduced.

Clutch compressor kit

Special tools for clutch compressors make easy work of assembling and dismantling the clutch, assembly of the actuator piston, and fixing the toothed drive-wheel.

Special bayonet ring tool

This intuitive tool was developed to enable fast and simple release and tightening of the ring on bayonet-style air drier cartridges.

TEBS tool kit

The problem: TEBS modules can be mounted in various places on the trailer – the surrounding area may be narrow, or there may be limited space to exert the necessary force on the release plugs and connectors.

The solution: Using the Extractor Tool avoids damage and simplifies the release and tightening of the power supply connectors for the trailer EBS module, for both those with a bayonet fitting and those with pole-connector style fittings. Technicians can work overhead so the job is more comfortable and, because the technician has better control and is able to exert more force, it’s faster and easier.

How it works: There is a two-part handle so getting a comfortable fit is easy. The Bayonet Removal tool is simply placed on the bayonet and turned clockwise. It can be used on its own or, if access is extremely limited, in conjunction with a ratchet. It has a square key, making it possible to use a standard ratchet. The Socket Connector tool is used to release pin pole-style plug connectors. The kit contains three separate tools for removing 2-pole, 6-pole, and 12-pole connectors.