Panel Systems, a distributor of Thermhex, looks at how fleets can benefit from the use of lighter materials for trailers and commercial vehicle bodies.

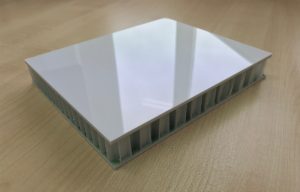

ThermhexManufactured in Germany in an innovative, patented process which ensures rigidity in terms of its mechanical strength, as well as stability, Thermhex is resistant to chemicals and moisture. In addition as part of ensuring ethical and sustainable sourcing of materials, it is also 100% recyclable.

The material can be purchased in a standard sheet of 2500mm x 1200mm, or Panel Systems can supply bespoke sizes up to a maximum of 7000mm in length. Thermhex is supplied in thicknesses ranging from 3.5mm to 30mm and is also available in different core densities to suit specific applications.

Reducing the weight of commercial vehicles is number one on many fleet managers’ wish lists. Whilst truck body and trailer manufacturers are focused on identifying and making use of materials that are lighter in weight but equally rigid, fleet managers are welcoming alternative materials that could help to reduce fuel usage and a fleet’s carbon footprint.

Fuel usage of an average fleet is determined by a number of controllable factors, such as the rate of acceleration and the age and proper inflation of tyres. Other factors beyond a driver’s control include wind speed, traffic and temperature, to name just a few.

Fuel consumption

In order to reduce fuel consumption, many fleet managers are focusing on two key areas: firstly, how their vehicles are being driven and secondly, what their vehicle bodies are made from.

Research conducted by Massachusetts Institute of Technology found that depending on driving style adopted and road conditions, reducing the weight of the vehicle by 35% could cut fuel consumption by 12 to 20%. Commercial vehicle and trailer manufacturers are therefore naturally looking to take weight out of their products, whilst ensuring that they still retain strength and rigidity.

Due to its weight saving properties, Thermhex, the polypropylene honeycomb core material, has been increasing in demand with commercial vehicle and trailer manufacturers.

Owing to its lightweight but rigid structure, the material provides the perfect solution for commercial vehicle fleets that are looking to lower their fuel consumption and emission levels.

A typical dry freight truck panel, manufactured from an 18mm Thermhex core, faced with 2mm Glass Reinforced Plastic (GRP) on each side, would weigh around 7.6kg/m2. In comparison, a panel of the same size with a plywood core would weigh approximately 13kg/m2. This results in a weight saving of 41% and in turn a reduction in fuel consumption and emissions, making vehicles manufactured with Thermhex more economical to run and better for the environment. Home delivery operators have some of the largest fleets in the UK nowadays and recently Panel Systems supplied Thermhex for a fleet of new trucks that will be used as delivery vehicles for an online retailer. The material will be used to form the bodywork to ensure maximum payload capabilities.

In addition, Thermhex is already well established as a material of choice across mainland Europe for applications ranging from automotive, truck bodies, the marine industry, OEM, industrial equipment and caravan markets.

The company claims that the future looks bright for lighter weight, rigid materials. With many trailer body manufacturers looking for an alternative to plywood, innovative lighter materials are demonstrating how they can help operators to make major savings. With emissions legislation set to be tightened further, there is a very real need to take these modern materials – and their associated benefits – seriously.