David Kaiser, Head of Research and Development at Liqui Moly, explains how additives are not only useful chemical tools, but also high-margin revenue generators.

In order to benefit from this, the workshop not only needs some technical understanding of how additives work, they must also be able to share their knowledge with their customers. First of all, additives are an additional cost for fleet operators that they want to avoid. In fact, they can end up saving money – and the workshop can make money.

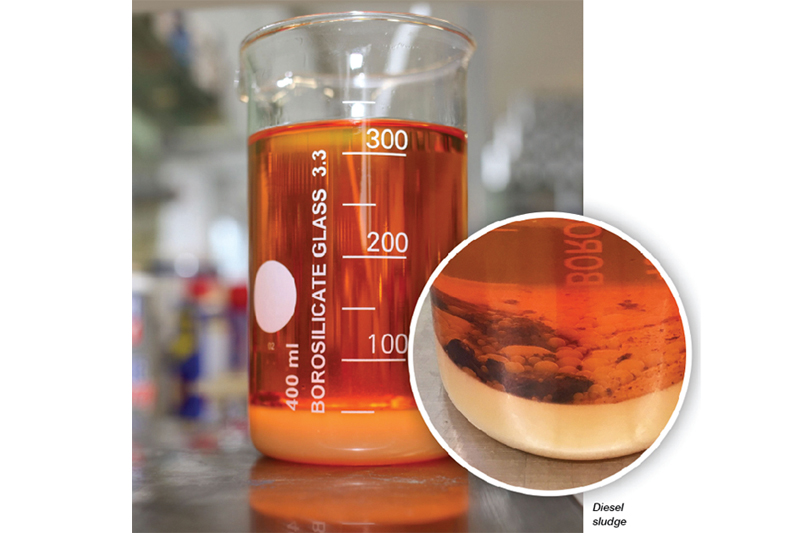

Diesel sludge

If diesel vehicles are decommissioned for a long time, whether because they’re not needed in winter, or for non-seasonal reasons, there is a risk of diesel sludge. Diesel sludge involves the water in the fuel causing problems. The water comes from the air humidity, which condenses on the inner walls of the fuel tank, but it can also be contained in the diesel fuel itself in the event of a poor-quality fuel.

When a vehicle is stationary for an extended period of time, the water settles at the bottom of the tank because it is heavier than the diesel fuel. The boundary between water and diesel offers excellent living conditions for certain bacteria, so they multiply.

“These bacteria form what is known as diesel sludge – a slimy mass that can potentially clog the fuel filter and interfere with combustion. This requires tedious cleaning of the entire fuel system,” says David Kaiser. The downtime and additional costs have to be borne by the vehicle owner.

But this can easily be avoided if the necessary provisions are taken in good time. Liqui Moly’s Anti-Bacterial Diesel Additive provides reliable protection from diesel sludge. When added to the fuel tank, it prevents bacteria from multiplying, thereby stopping the formation of the sludge that can cause problems later. The dosage is 1:1000, so it is not even very expensive to use. It is even more economical when purchased in large containers: these can be as large as 60-litre drums, enabling fleet operators to supply their own filling station. The few pounds for the additive is well invested since it helps avoid much higher costs later on.

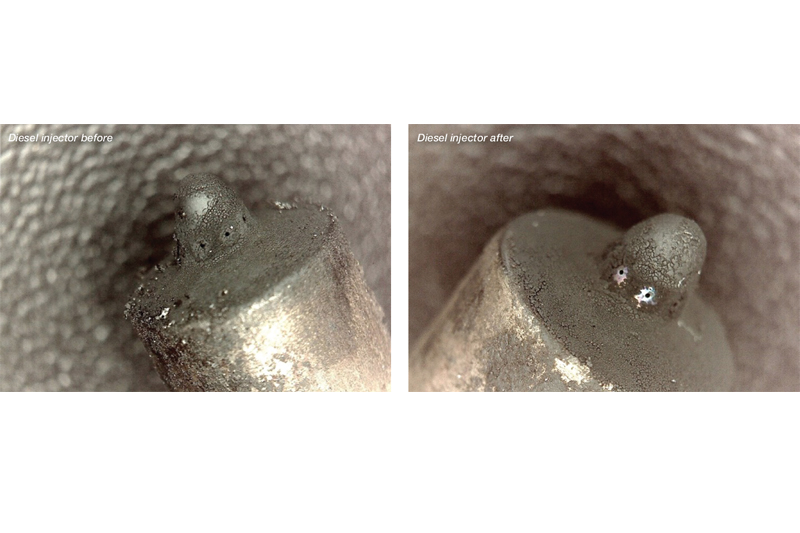

Soiled diesel injectors

The second example is soiled diesel injectors. It is natural for combustion residue to settle on the injection nozzles. But this impairs the spray pattern and the fuel combustion process is no longer as clean as it should be. The result is reduced power and higher fuel consumption. In addition, more combustion residue is now created, thereby exacerbating the problem – so we have a vicious circle. What happens is that this is a very slow process and often not noticed. It not only results in a loss of power and increased fuel consumption, however, it also increases maintenance costs. The encrustations shorten the service life of the injectors and increase the risk of downtime.

This can be avoided by using Liqui Moly’s Super Diesel Additive. It cleans the injection nozzles, removes any soiling and ensures that no new residue can settle. This is all the more important nowadays because modern engines are very sensitive to dirt – the downside of their higher efficiency. Super Diesel Additive restores original performance and fuel consumption.

Freight forwarder Dirk Sauer uses Super Diesel Additive in the stationary Volvo lorry engines in operation at his combined heat and power plant. These engines sometimes run for 24 hours at a stretch at maximum load. “We were able to reduce fuel consumption from 75 litres to 72 litres per hour,” says Dirk Sauer. “This alone saves us about 2,160 litres of fuel per month. It’s good for our budget – and great for the environment, too.”

Super Diesel Additive by Liqui Moly is a multi-purpose weapon in the fight against diesel problems. It not only cleans the injectors, it also lubricates them, thereby increasing their service life. This saves maintenance costs and reduces downtimes. “Previously, we had to replace the expensive injectors every year due to the high loads”, says Dirk Sauer. “Since we started using Liqui Moly, we’ve had no damage or malfunction in the expensive injectors at all.”

And Super Diesel Additive is capable of even more: it increases the cetane number. This improves the ignition properties of the fuel, so the engine runs more quietly and economically. What is more, it protects the entire fuel system from corrosion.

For fleet operators, Super Diesel Additives are also available in large containers – including drums of up to 205 litres – and in the form of a concentrate, too. This reduces costs per litre and makes the use of Super Diesel Additives particularly economical. It means you can use the additive at your own filling station. In this way, you avoid any cumbersome handling of cans when refuelling and you can ensure every vehicle really does benefit from the advantages the additive has to offer.

Super Diesel Additive and Anti-Bacterial Diesel Additive are just two examples of the numerous additives available from Liqui Moly. They not only generate extra business for workshops, the products also allow workshops to demonstrate to customers that they are protecting them from problems and helping them save money. The wide range of additives enables workshops to offer their customers tailor-made service packages.